- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- functional testing

Results for

Functional testing - Import export

SUZHOU CSL PRECISION CO., LTD

China

CSL Precision has several skilled and expertised engineers who is helping our customers in the design stage to have the earlier engineering involvement. Product Drawing, Testing Method/Criterial,Function requirement, Assemby SOP, etc. can be set up too by CSL Precision.

Request for a quote

HOMKEY PACKAGING COMPANY LIMITED

China

Assist in the design and development of unique packaging solutions tailored to the client's products. Create prototypes and mock-ups to test the functionality and aesthetics of the packaging before final production.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Precision aluminum anodized cnc turning ring parts Surface: anodized gold Material: AL6061-T6 Tolerance:within 0.02mm Usage: machine Manufacturing process: cnc turning parts Machining Euipment: cnc turning machine Testing equipment: projector We are willing to provide with sample for quality and function testing.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Specialty cnc turning stailess steel parts Surface: as your requirement Material: steel / aluminum / brass / iron / zinc / alloy Any other material and dimension depends on customers' demand. Usage: machinery / furniture / toy / woodboard / wall Manufacturing process: cnc machining Euipment: cnc machine Testing equipment: projector Tolerance:+/-0.05MM We are willing to provide with sample for quality and function testing.

Request for a quote

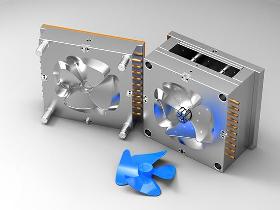

XUFENG TOOL TECH GROUP LIMITED

China

Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . We manufacture our rapid toolings in material aluminium, P20, NAK80 and S136 tool steel, which can be run in a standard injection moulding machine to produce production quality parts in low-volumes. P20 prototype tooling for volumes up to 50,000+ shots. NAK80 or S136 prototype tooling for volumes up to 100,000+ shots. Prototype tooling in 5 to 28 calendar days. Tooling Lead-Time get short leadtime, Low Cost - reduced Cost from material ,MFG , Allowing real trials ,Allows functional test of parts on initial design stage, Many design faults are debugged before mass big production.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Functional testing - Import exportNumber of results

5 ProductsCountries

Company type