- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical insulation

Results for

Electrical insulation - Import export

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Electrical Insulation and Extremely High Voltage; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

PEEKCHINA CO., LTD.

China

Glass Filled PEEK Properties PEEK glass filled into a versatile material capable of meeting specific application requirements. Industries such as aerospace, automotive, medical, and many others benefit from this tailored enhancement, allowing them to leverage PEEK's exceptional properties in diverse and demanding settings. The degree of glass fiber reinforcement can be adjusted to achieve the desired balance of properties for each unique use case.

Request for a quote

PEEKCHINA CO., LTD.

China

This high-performance material boasts exceptional mechanical strength, chemical resistance, and thermal stability, making it the ideal choice for precision engineering and complex component manufacturing. Lightweight yet durable, our PEEK sheet excels in high-temperature environments and offers excellent electrical insulation properties.

Request for a quote

PEEKCHINA CO., LTD.

China

Experience the versatility and durability of our high-quality PEEK Thin Sheet/Plate. Available in various thicknesses, including 0.5mm, 0.6mm, 0.8mm, and 1.0mm, these thin sheets are designed to meet the demands of a wide range of applications. PEEK (Polyetheretherketone) is renowned for its exceptional properties, including high temperature resistance, chemical resistance, and mechanical strength. Whether you need a thin sheet for electrical insulation, aerospace components, or medical devices, our PEEK Thin Sheet/Plate delivers reliable performance. The precise manufacturing process ensures uniform thickness and smooth surface finish, allowing for easy fabrication and excellent dimensional stability. Its lightweight nature makes it a preferred choice in weight-sensitive applications without compromising on strength.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK (Polyether Ether Ketone) heat shrink tubing is revolutionizing the medical device industry with its exceptional properties and reliable performance. Known for its high-temperature resistance, chemical resistance, and mechanical strength, PEEK heat shrink tubing provides unparalleled protection and insulation for sensitive medical equipment. Whether it's ensuring the durability of surgical instruments or protecting the intricate wiring of diagnostic devices, PEEK tubing is the ideal choice for enhancing the safety, efficiency, and longevity of medical devices. Its low flammability and excellent electrical insulation further contribute to its suitability in critical healthcare applications, making it an essential component for medical device manufacturers seeking high-performance solutions.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride heat shields and magnetic rings are mainly used to protect high voltage electrodes and are widely used in the photovoltaic industry.Heat shields and magnetic rings, as well as ceramic rings, are collectively referred to as electrode shields.Silicon nitride electrode protection cover mainly uses silicon nitride insulation, heat resistance and corrosion resistance.Compared with the protective cover of quartz and alumina which is still in use today, the service life of the silicon nitride electrode shield is more than 10 times, and it will not be electrically broken down during use, and will not be heated, nor will it be heated. Will be eroded away. Due to its own stability, in the use of photovoltaic reduction furnaces, the collapse rate of non-human factors is greatly reduced. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

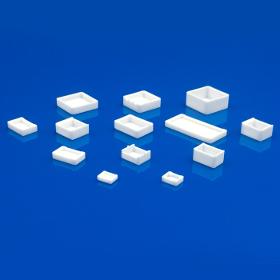

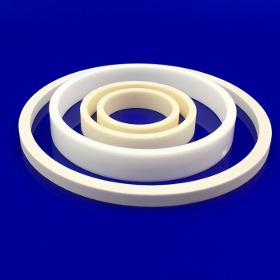

Alumina ceramic is a kind of ceramic material with a-al2o3 as the main crystal phase, because of its own high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be used in more stringent conditions. Alumina ceramics, with low price and mature production process, is one of the largest and most widely used ceramic materials, mainly used in the field of cutting tools, wear-resistant parts, and bioceramics. In addition, it is also widely used in energy, aerospace, chemical electronics, and other aspects. Especially 95% alumina and 99% aluminas, whether in structural ceramics or electronic ceramics are one of the most widely used ceramic materials. .Purity:92%,96% and 99.7% .Good mechanical strength .Excellent electrical insulation .High-frequency loss .Good thermal conductivity .Heat,wear and corrosion resistance Alumina is the best-known advanced ceramic material, is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1. Good thermal shock resistance 2. Creep resistance 3. Low density 4. High fracture toughness 5. High hardness and wear resistance 6. Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as aluminum oxide (Al2O3), is the most mature and commonly used technical ceramics. With excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina content ranging from 80% to more than 99% according to different application. It's widely used in automotive, petro-chemical, fluid contro, material transfer, industry, electrical and electronic, semiconductor,etc... - High Temperature Ability - Abrasion Resistant - Wear Resistance - Chemical Resistance - Electrical Insulator - Corrosion resistant - High compressive strength - High mechanical Strength - Resists strong acid and alkali attack at high temperatures - Excellent electrical insulation properties - Decent thermal conductivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

With its properties of electrical insulation and excellent thermal conductivity, Aluminum Nitride Ceramics is ideal for applications where heat dissipation is required. In addition, since it offers a coefficient of thermal expansion (CTE) near that of silicon, and excellent plasma resistance, it is used for semiconductor processing equipment components.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic plate is composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements * High Temperature Electrical Insulators * Extreme temperature measurement components * Ceramic Laser components * High voltage electrical insulators

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. In addition, it is extremely resistant to wear and corrosion and is an industrial ceramic that can only be formed by diamond grinding. The melting point is very high at 2,072°C, and it is very hard. Alumina components can be widely used in electronics, pump components and automotive sensors.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Technical ceramics are favoured in a wide range of electronics and engineering applications for their chemical and mechanical properties. Compared to metals, they are stronger in compression, especially at higher temperatures. Ceramics have a good thermal stability (i.e. a low coefficient of thermal expansion) and good thermal and electrical resistance. They are also hard, and have excellent dimensional stability. Al2O3 Properties: Excellent electrical insulation Relatively low strength and fracture toughness Resistance to wear and corrosive Excellent thermal stability Resistance to high temperatures High electrical resistivity Good chemical stability High corrosion resistance

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Pellet Igniter Information Ceramic Boiler Ignition Igniter surface can reach a permanent working temperature above 900℃;Since air can through and around inside and outside of the heater tube. Heat can be transferred from both inside and outside of ther heater element. Igniting wood chips, firewood, coal bricks or other biomass fuel. Specification: Voltage: 120V / 230V Power: 150W / 170W / 200W / 230W Tube Size: OD10.5 × ID6.5 × L78 mm Supporting Socket: NO.7 Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) Range of temperature: 800~1100 °C Alumina Pellet Igniter Advantages 1) Higher temperature, about twice of traditional metal sheathed heater; 2) Shorter ignition time, about 60~90 seconds 3) Electrically insulated with no exposed electric contacts 4) Wear and corrosion resistance 5) Long life time 6) Easy to install and replace 7) Long-lasting (non-aging). Tested to 100,000 cycles. 8) 800~1100°C at steady-state temperature.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

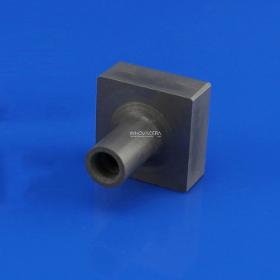

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher. Advantages of Ceramic-to-Metal Seals * More solid, durable hermetic seal and better electrical insulation * Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments * High mechanical strength, less fracture when applied to high vibration and high g-load conditions * Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic tubes are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. * Good electrical insulation * High dimensional tolerances * Excellent corrosion resistance * Very high working temperatures * Excellent thermal shock properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic tubes are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. * Good electrical insulation * High dimensional tolerances * Excellent corrosion resistance * Very high working temperatures * Excellent thermal shock properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Porous ceramic rods description: Porous ceramic filter rods are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. * Good electrical insulation * High dimensional tolerances * Excellent corrosion resistance * Very high working temperatures * Excellent thermal shock properties Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Aluminum AL2O3 Ceramic Water valve plate Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical,automotive, semiconductor, textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc. Customized designs are very often to be made. 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The protective tube of silicon nitride material has high thermal conductivity, high temperature resistance, corrosion resistance,non-wetting with molten metal, and electrical insulation, making it the best choice for heating body protection tubes. The advantage of the immersion holding furnace is very obvious, and in order to achieve the immersion of the heating element into the molten metal, it is necessary to have a protective tube which can protect the heating element well. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quoteResults for

Electrical insulation - Import exportNumber of results

48 ProductsCountries

Company type