- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper%20alloys

Results for

Copper%20alloys - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product Name: Copper Tin Nickel Alloy Width:10-630mm Material:Bronze Grade: Oxygen Free Copper Cu (Min): 75% Model Number:Copper Alloy Place of Origin: China Size: Customised Standard: JIS ASTM DIN EN ISO Certificate: SGS / ROHS / ISO9001:2008 Package: standard export packing Price Term: CIF CFR FOB Ex-Work etc. Usage: Electric Components Lead time:20 Days

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin: China Shape: as required Length: Customized Grade: Brass Cu (Min): 57%-59% Alloy Or Not: is Alloy Type: copper bar Certification: SGS MOQ: 100 kgs OEM Service: Accept Supply Ability: 50 Ton/Tons per Week Packaging Details:standard export packing Port of shipment:Xiamen,China Lead Time :15-30days Payment term: T/T,L/C etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Hai Tong have high speed press range from 25 to 60 tons utilizing Micron high speed press introduced from Taiwan, We stamp ferrous, non-ferrous, copper based alloys, stainless steel, aluminum,with speeds up to 1500 SPM. We manufacture quality and premier product and we always exceed our customers' expectations. Our progressive die stamping services are perfect for manufacturing components with tight tolerances of +/-0.01mm. We have 15 years of toolings fabrication experience and can consult on any project including failure analysis. We produce pins, copper contact, copper terminal, printed circuit contacts, and much more, which are used on switch, plug,s ocket, computer, household appliance,etc

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

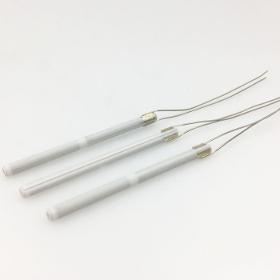

Electric 12V 13V Alumina Ceramic Heating Element Heater Rod for Oxygen Sensor Advantages Ceramic Heater for Oxygen senster is used for heating oxygen sensors that detect the exhaust gas of vehicles and is equipped to most of automobile gasoline engines. Because the temperature can be rapidly raised, it is possible to activate the sensor immediately after the engine start which provides useful feedback to reduce emissions. 1.Based material: a.white alumina ceramic b.the content of alumina is no less than 95%. c.the tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C 2.Ni-wires:N6 Ni-wires with 0.6mm diameter 3.Brazing material: siliver-copper braging alloy

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher. Advantages of Ceramic-to-Metal Seals * More solid, durable hermetic seal and better electrical insulation * Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments * High mechanical strength, less fracture when applied to high vibration and high g-load conditions * Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Heater for Soldering iron & Station: Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before.Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries. a.Based material: white alumina ceramic, and the content of alumina is no less than 95%.The tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C b.Ni-wires:N6 Ni-wires with 0.6mm diameter c.Brazing material: siliver-copper braging alloy Application: We are producing High Quality 24V 110V 220V Heating Element for Soldering Station with the advantages of energy-efficient,long lifetime,high insulation,super fast heatin up and eco-friendly.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material:Stainless steel, copper alloy,aluminum alloy and so on Surface treatment:Polishing, Zinc plating, Nickel plating, Chrome plating, powder coating, Anodizing, E-coating Drawing operation:PDF, JPG, Auto CAD, Pro/Engineer, Solid Works, UG. Etc. Industry:Automotive, Electrical, Building, Furniture,Mechanical, Machine assembly, Computer, Air industry. Electronics etc. Professional team :Over 10 years experience in metal fabrication Delivery time:Strictly according to customer confirmed order. Package detail:Standard export package or as customers' specific requirement

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Materials: stainless steel, carbon steel, alloy steel, aluminum, zinc alloy, copper, brass,POM, PC, PA, Teflon, PVC and ABS Process: raw material, rough machining, finish machining Surface treatment: plating, spraying, anodizing, electro polishing and coating Tolerance: ±0.01mm OEM/ODM orders are welcome Customized designs are welcome Standards: DIN, JIS, ASTM, AISI, BS and GB Packaging: precision machining parts Inner: PE bag or customized Outer: wooden case or carton or customized Size: customized

Request for a quoteResults for

Copper%20alloys - Import exportNumber of results

12 ProductsCountries

Company type