- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramic materials

Results for

Ceramic materials - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

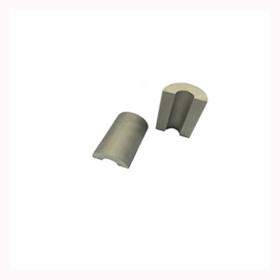

Features: Made of ground sintered SmCo magnet Powder is mixed with resin and molded like NdFeB bonded magnet No need to be coated because it is difficult to erode and oxidize High-BH (maximum) High-Br and Hc with high-operating temperature, low-temperature coefficient, counter-demagnetization, decay resistance Main products cover SmCo5 and Sm2Co17 magnets, samarium cobalt powder, various assemblies and more OEM orders are welcomed Applications: Widely used in motors, watches, transducers, instruments, positional detectors, generators, radars and more High quality, competitive price, best service

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Silicon carbide is a kind of inorganic non-metallic materials, with excellent mechanical strength and hardness, small creep deformation, good oxidation resistance, good corrosion resistance and good wear resistance, it is an ideal choice for high temperature engineering materials. Due to the outstanding properties, silicon carbide ceramic is also recognized as a mechanical sealing ring material better than metals, tungsten carbide, al2o3 ceramics and more. Place of Origin: China Material: Silicon Carbide (SiC) Color: Black/grey Material: Silicon Carbide Ceramics Volume density: 3.10-3.15 g/cm3 Max temperature: 1600°C Silicon carbide content: ≥98% Flexural Strength: ≥400 MPa Hardness: ≥ 92 HRA Size: Customizable Application: Industrial Furnaces Supply Ability: 5000000 Piece/Pieces per Month Packaging Details: Standard exporting packing Port of shipment: Xiamen Lead Time :15-30days Payment term: T/T,L/C etc.

Request for a quote

PEEKCHINA CO., LTD.

China

Ceramic PEEK Material Discover the art of precision engineering with Ceramic Filled PEEK Rods. Their exceptional machinability enables manufacturers to achieve intricate designs and complex shapes effortlessly. Combined with high strength and good stiffness, these rods ensure your components maintain their integrity, even under demanding conditions. Trust in Ceramic Filled PEEK Rods for reliable performance and seamless machining, elevating your projects to new levels of excellence.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Ceramic Composites Elevate your applications with our PEEK ceramic composite. This advanced material combines the exceptional properties of PEEK with the added strength and durability of ceramic. Experience enhanced mechanical performance and wear resistance, making it the perfect choice for demanding industrial solutions. Choose PEEK filled with ceramic for precision and resilience in extreme conditions.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

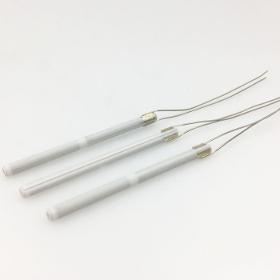

Electric 12V 13V Alumina Ceramic Heating Element Heater Rod for Oxygen Sensor Advantages Ceramic Heater for Oxygen senster is used for heating oxygen sensors that detect the exhaust gas of vehicles and is equipped to most of automobile gasoline engines. Because the temperature can be rapidly raised, it is possible to activate the sensor immediately after the engine start which provides useful feedback to reduce emissions. 1.Based material: a.white alumina ceramic b.the content of alumina is no less than 95%. c.the tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C 2.Ni-wires:N6 Ni-wires with 0.6mm diameter 3.Brazing material: siliver-copper braging alloy

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Heater for Soldering iron & Station: Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before.Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries. a.Based material: white alumina ceramic, and the content of alumina is no less than 95%.The tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C b.Ni-wires:N6 Ni-wires with 0.6mm diameter c.Brazing material: siliver-copper braging alloy Application: We are producing High Quality 24V 110V 220V Heating Element for Soldering Station with the advantages of energy-efficient,long lifetime,high insulation,super fast heatin up and eco-friendly.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Laser Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters: 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

No other oxide ceramic material collectively exhibits these highly desirable properties and characteristics. BeO ceramic conducts heat more quickly than virtually all metals with the exception of copper and silver. Beryllia exhibits extremely low dielectric loss characteristics, possesses high electrical resistivity, and offers excellent strength with high specific stiffness properties. BeO provides all the desirable physical and dielectric characteristics exhibited by an aluminum oxide or aluminum nitride, in addition, offers thermal conductivity ten times higher than alumina, and fifty percent higher than aluminum nitride, a dielectric constant that is lower than both alumina and aluminum nitride, and weight per given volume that is fully a quarter less than alumina, and nearly ten percent less than aluminum nitride. As a thermally conductive and electrically insulating material, its performance is exceeded only by that of the diamond.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

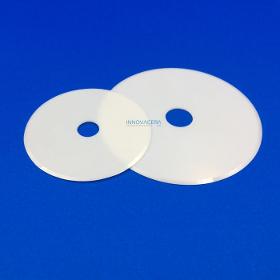

Ceramic Rotary Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Durable Zirconium Oxide Ceramic Scalpel/INNOVACERA Technical cutters made of reinforced zirconium oxide ceramics are the standard material of choice in many machines and applications. we can supply product upon request. Product features: 1,Faster cutting rates 2,Consistently good cutting quality, e.g. improved strength of spliced connections 3,No corrosion 4,Smooth running 5,Extended maintenance intervals 6,Universal cleaning possibilities using acids, alkaline solutions and organic solvents Product application: 1,textile industry 2,Medicine 3,Food and beverage production 4,Automotive

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Trapezoid Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride (Si3N4) is a high-melting-point material with high fracture toughness and excellent thermal shock resistance, It is considered to be one of the few monolithic ceramic materials that can withstand severe thermal shock and thermal gradient generated by hydrogen and oxygen rocket engines.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia is a very strong industrial ceramic with excellent properties in terms of hardness, fracture toughness and corrosion resistance; it solves the most common characteristic of ceramics-high brittleness. Its unique crack propagation resistance and high thermal expansion make it an excellent material for joining ceramics and metals such as steel. Due to the unique properties of zirconia, it is sometimes referred to as “ceramic steel”.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

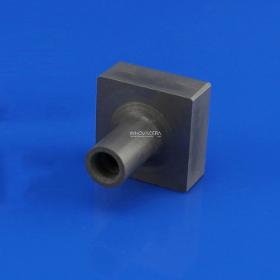

Innovacera provided advanced ceramic solutions for fluid dispensing and filling in the pharmaceutical, cosmetic and food industries.Our pumps and valves are made in advanced ceramic materials.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. In addition, it is extremely resistant to wear and corrosion and is an industrial ceramic that can only be formed by diamond grinding. The melting point is very high at 2,072°C, and it is very hard. Alumina components can be widely used in electronics, pump components and automotive sensors.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel. > high fracture toughness > thermal expansion similar to cast iron > extremely high bending strength and tensile strength > high resistance to wear and to corrosion > low thermal conductivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: * Surface grinders * CNC milling machines * Jig grinders * Centerless grinders * CNC lathes * ID grinders

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Si3N4 Silicon Nitride Tube Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1. Good thermal shock resistance 2. Creep resistance 3. Low density 4. High fracture toughness 5. High hardness and wear resistance 6. Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Factory Custom Silicon Nitride Thermal Substrate for High Power Radiator Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel. Features: > high fracture toughness > thermal expansion similar to cast iron > extremely high bending strength and tensile strength > high resistance to wear and to corrosion > low thermal conductivity Ceramic material composition: . TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quoteResults for

Ceramic materials - Import exportNumber of results

69 ProductsCountries

Company type

Category

- Ceramics (65)

- Ceramics, industrial (47)

- Ceramics, refractory (7)

- Silicones (1)

- Ceramic manufacturing - machinery and equipment (1)

- Ceramic, components - electric (1)

- Driveshafts and micro-motors - electric (1)

- Metal detectors (1)

- Plastic products for engineering (1)

- Plastic products for the electrical industry (1)