- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chemical degreasers

Results for

Chemical degreasers - Import export

LAMBIOTTE & CIE

Belgium

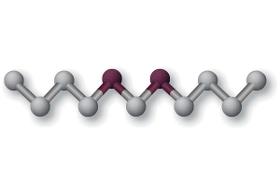

Molecular formulaC9H20O2 Molecular weight160.3 CAS number2568-90-3 EC number219-909-0 IUPAC name1-(Butoxymethoxy)butane EC name1.1'-[Methylenebis(oxy)]dibutane

Request for a quote

ROCHOLL GMBH

Germany

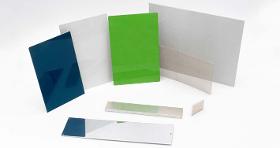

Are you aware of our finishing options for metal and aluminum test specimens? Chemical degreasing, deburring, grinding, turning, milling, punching or blasting – no problem. Upon request, test specimens can be customized and labeled with serial numbers. Contact us to find out how we can help you. By the way: we can manufacture test specimens for the TABER-ABRASER from all kinds of metals.

Request for a quote

VINCO

Spain

EN AW-6016 (Al Si1,2Mg0,4) - EN 485 T4 EN 485 EN AW-6016 (Al Si1,2Mg0,4) - EN 485 T6 EN 485 EN AW-6082 (Al Si1MgMn) - EN 485 O EN 485 EN AW-6082 (Al Si1MgMn) - EN 485 T4 EN 485 EN AW-6082 (Al Si1MgMn) - EN 485 T6 EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 O EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 T6 EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 T76 EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 T73 EN 485 EN AW-8011A (Al FeSi(A)) - EN 485 O/H111 EN 485 EN AW-8011A (Al FeSi(A)) - EN 485 H18 EN 485 EN AW-8011A (Al FeSi(A)) - EN 485 H24 EN 485 FINISHES: Under a commercial agreement We are able to supply aluminium that can be anodised or is anodised We also offer the following material cleaning options (depending on the alloy): Wash Chemical degreasing

Request for a quote

VINCO

Spain

EN AW-1050A (Al 99,5) - EN 485 0/H111 EN 485 EN AW-1050A (Al 99,5) - EN 485 H14 EN 485 EN AW-1050A (Al 99,5) - EN 485 H16 EN 485 EN AW-1050A (Al 99,5) - EN 485 H18 EN 485 EN AW-1050A (Al 99,5) - EN 485 H22 EN 485 EN AW-1050A (Al 99,5) - EN 485 H24 EN 485 EN AW-1050A (Al 99,5) - EN 485 H26 EN 485 EN AW-1070 (Al 99,7) - EN 485 0/H111 EN 485 EN AW-1070 (Al 99,7) - EN 485 H18 EN 485 EN AW-1070 (Al 99,7) - EN 485 H22 EN 485 EN AW-1070 (Al 99,7) - EN 485 H24 EN 485 EN AW-1200 (Al 99,0) - EN 485 0/H111 EN 485 EN AW-1200 (Al 99,0) - EN 485 H14 EN 485 EN AW-1200 (Al 99,0) - EN 485 H18 EN 485 EN AW-1200 (Al 99,0) - EN 485 H19 EN 485 EN AW-1200 (Al 99,0) - EN 485 H24 EN 485 FINISHES: Under a commercial agreement We are able to supply aluminium that can be anodised or is anodised We also offer the following material cleaning options (depending on the alloy): Wash Chemical degreasing

Request for a quote

KITTNER ANLAGEN - UND MASCHINENBAU

Bulgaria

The machine is designed for cleaning, degreasing, chemical treatment of the outer layer and blowing of small components. The parts are arranged in trays with dimensions 600x400x70-150 mm. Two washing zones – pre-washing zone and zone for main washing. After each washing zone there is zone for blowing. The pre-washing zone has an external band filter, which is with the possibility of processing a high volume of washing solution and captures particles of a size greater than 350 μm. The band filter cleaning the washing solution of oil and hard dirt. The mainly washing zone has a column bag filter, which captures particles of a size greater than 50 μm. Both filters have monitoring systems for the degree of soiling and in case of clogging the machine stops. Automatic dosing of the cleaning agent. Machine corpus made entirely out of stainless steel, material No. 1.4301. The machine complies with the high CE-Requirements and EU- and USDA regulations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OSMO MEMBRANE SYSTEMS GMBH

Germany

Degreasing bath treatment Ultrafiltration is established for a long time for applications like treatment of emulsions, degreasing baths or craft detection oils. With ultrafiltration, oil and dirt particles are separated. So, the particle-free filtrate can be used for degreasing again. According to the recommendations of suppliers for degreasing chemicals tensides are added to the degreasing bath. So, lifetimes up to 3 to 6 months can be reached for degreasing baths. Osmo Membrane Systems GmbH offers an upgrade for your degreasing plant in replacing the polymer pipe modules by ceramic modules. Ceramic modules are more temperature resistant, chemical resistant and changing pH-values. On the one hand, the separation efficiency will be increased and on the other hand, the lifetime of the degreasing plant will be increased significantly, because polymer modules have to be changed much more, depending on the application. The costs for the upgrade are equal to the costs for working with poly

Request for a quoteResults for

Chemical degreasers - Import exportNumber of results

7 ProductsCountries

Company type