- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- check weight

Results for

Check weight - Import export

MH MULTIPACK SDN BHD

Malaysia

Vacuum Stoppering system to minimize entrapped filling & drip-free. Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion. Valveless Rotary Piston pump for Hygiene Filling. Contact parts are FDA Approved material and autoclavable. Optional Laminar Air Flow Booth. Optional N2 flushing. Optional FDA 21 CFR Part 11. Optional Realtime Equipment OEE monitoring anytime, anywhere. Optional 100% Weight In Process Control of filling weight system by tare in / tare out to obtain nett filling weight check.

Request for a quote

MH MULTIPACK SDN BHD

Malaysia

Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion. Valveless Rotary Piston pump for Hygiene Filling. Contact parts are FDA Approved material and autoclavable. Laminar Air Flow Booth. Auto rejection without machine stop. Optional 100% IPC Tare-in, Tare-out weight check. Optional N2 flushing. Optional FDA 21 CFR Part 11. Optional Realtime Equipment OEE monitoring anytime, anywhere.

Request for a quote

MH MULTIPACK SDN BHD

Malaysia

Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion. Valveless Rotary Piston pump for Hygiene Filling. Contact parts are FDA Approved material and autoclavable. Laminar Air Flow Booth. Auto rejection without machine stop. Optional 100% IPC Tare-in, Tare-out weight check. Optional N2 flushing. Optional FDA 21 CFR Part 11. Optional Realtime Equipment OEE monitoring anytime, anywhere.

Request for a quote

MH MULTIPACK SDN BHD

Malaysia

Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion. Precision Auger Filling System with wide filling range without change part. Bottle lifted during filling for clean filling. Swingable Filling module for easy dismantle when cleaning. Contact parts are FDA Approved material and autoclavable. Patented Elevator cap sorter without vibration noise, less than 70dB. Cap closing torque are servo control for highest consistency. Auto rejection without machine stop. Optional 100% IPC Tare-in, Tare-out weight check. Optional N2 flushing. Optional FDA 21 CFR Part 11. Optional Realtime Equipment OEE monitoring anytime, anywhere. Machine Specification

Request for a quote

MH MULTIPACK SDN BHD

Malaysia

Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion. Precision Auger Filling System with wide filling range without change part. Bottle lifted during filling for clean filling. Swingable Filling module for easy dismantle when cleaning. Contact parts are FDA Approved material and autoclavable. Auto rejection without machine stop. Laminar Air Flow Booth. Optional 100% IPC Tare-in, Tare-out weight check. Optional N2 flushing. Optional FDA 21 CFR Part 11. Optional Realtime Equipment OEE monitoring anytime, anywhere

Request for a quote

MH MULTIPACK SDN BHD

Malaysia

Aseptic Nested Filing Line from De-bagging, De-liding, Filling and Stoppering system. Vacuum Stoppering system to minimize entrapped filling & drip-free. “Trackless” Rubber stopper feeding to eliminate jamming at the track. Statistical Weight In Process Control of filling weight system by tare in / tare out to obtain nett filling weight check. Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion.

Request for a quote

FERPLAST SNC

Italy

Multifunction counter and floor scales. Capacity from 6 to 600 Kg - Division 2 to 200 grams. MODULAR SCALES FOR COUNTER AND FLOOR "WALL-E" Counter or floor scales complete of multifunction weight indicator FPDFWL BASE 6-digit standard. They have a strong and solid structure and a load of stainless steel. Extremely easy to use and versatile, guaranteeing precision and reliability. They are particularly suitable for the industry and commerce. Available also CE-M APPROVED for sale to third parties, according to OIML R-76/EN 45501. TECHNICAL FEATURES WEIGHING PLATFORM Precise and sturdy structure, suitable for creating scales and automatic weight checking systems for all industrial and commercial applications. Stainless steel top. Standard version works with aluminum cell 3000d with IP65 protection.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Essentus® range of dynamic checkweighers offers four basic models for simple, precise weight and integrity checking of packaged foods and other products. Easy to operate Robust conveyer technology A wide range of belt lengths and widths Automatic learning function makes configuration easier (L/H performance) A wide variety of options (L/H performance) Automatic speed regulation (L/H performance)

Request for a quote

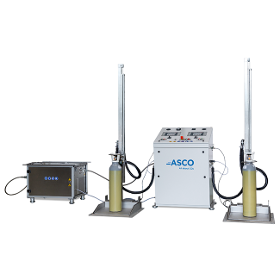

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quote

FERPLAST SNC

Italy

Box weighing system to be integrated in manual idle lines When the box is positioned on the weighing station, the operator can read and check the weight of the products inserted in the box before placing it on the pallet and thus avoid errors or returns of the goods. In this way the operator can view the result of the weighing on the weight indicator without having to lift the packages to weigh them. The weight indicator is usually installed on a vertical post clamped to the structure of the roller conveyor. In this way the indicator remains positioned vertically and it is very easy for the operator to read the weight. The standard version foresees the installation of the basic DFWL indicator. On request it is possible to install the 7-key indicator also with DFWKPXP printer. The rollers used for the roller conveyors have a diameter of 50 mm and a pitch of 75 mm

Request for a quote

DIBAL SA

Spain

From the simplest to the most demanding solutions. We adapt our checkweighers to comply with our clients’ specifications and their plants. This equipment helps you reach the required quality standards efficiently. Automatic equipment to check that a product’s weight is within a defined weight range. Dibal CW automatic checkweighers, with optional rejection system, check the correct weight of products without stopping the production line. If the weight is above or below the set range the equipment automatically rejects the product.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

Can be used for sorting 5 to 7 grades of weight; For raw food, bags, bottles, containers, and so on; SS304 stainless steel; 10-inch touch screen; Can store over 1 million entries, data export by USB.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

OIML R76 approved GMT-X1, a DIN rail-mounted weighing transmitter for industrial automation, can be used in various system weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc. Through Bluetooth, it can be connected to Weasy App for configuration and monitoring. Hardware Configuration: 1. Standard: RS4851 + RS485/RS232(Selectable) 2. Hardware Option1: 3 Input 5 Output or 3 Input 4 Output relay (Optional) 3. Hardware Option2: RS485+16bit Analog or 2 Input 4 Output 4. Hardware Option3: Modbus TCP or Ethernet/IP or Profinet (Hardware Option1,2,3 can be selected at the same time) 5. Bluetooth Communication

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GMT-X4 is a DIN rail-mounted weighing transmitter with four-channel. When one of the four channels' load cells is damaged, GMT-X4 will automatically identify and give an alarm by displaying the alarm message on the screen. It has the characteristics of compact design, stable performance, and easy operation, which can be used for various weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc. Different configuration choices, a variety of combinations; Standard: ① 4-channel of 6-wire load cell interfaces; ② RS485&RS232; ③ 4 Input 8 Output transistor I/O; Option1: Modbus TCP /IP or EtherNet/IP or ProfiNet or EtherCat; Option2: 4 analog output; Option3: 1CAN interface; (Option1,2,3 can be selected at the same time)

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GMT-X1, a DIN rail-mounted weighing transmitter for industrial automation, can be used in various system weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc. Through Bluetooth, it can be connected to Weasy App for configuration and monitoring.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GM8802S-C is a compact check weigher control module with the DIN rail mount installation method. It has an OLED display. The WEINVIEW 7-inch or 10-inch touch screen is the optional selection. It is suitable for weight checking or sorting in the production process of various industries, such as logistics, chemical, food, pharmaceutical, and electronics industries, and so on.

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

GMT-X4 is a DIN rail-mounted weighing transmitter with four-channel. When one of the four channels' load cells is damaged, GMT-X4 will automatically identify and give an alarm by displaying the alarm message on the screen. It has the characteristics of compact design, stable performance, and easy operation, which can be used for various weighing applications, such as weight checking, loss-in-weight, liquid filling, batching, vessel and silo weighing, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA CONSUMER GMBH

Germany

Filling: - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product - Synchronization interface for the bottling plant - Vibrating the containers under the filling positions for product compaction and optimal utilization of the container's volume Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-fc2

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing: - 100% tare/gross weighing - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - Volumetric dosing with auger filler - High-precision positioning for constant filling weight/volume Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Standard version with up to 2 working stations - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

EGESAN PRINTING AND PACKAGING

Turkey

During the production process, we are applying visual check , unit weight , thickness , stiffness and colour analysis tests in offset printing.

Request for a quote

OEG OFFSHORE LTD

United Kingdom

The OEG Offshore Cargo Basket range has been designed and manufactured in accordance with DNV 2.7-1 / BSEN 12079. The units are supplied with certified slings and shackles as standard. All units are stackable where deck space or yard space is at a premium. OEG Offshore Cargo Baskets can be supplied with cargo nets or tarpaulins and the base has integrated forklift pockets for ease of yard loading and offloading. OEG Cargo Baskets are supplied with internal tie down points through out the interior provide strong points to secure cargo. Optional guide rails and supports can also be provided to suit customer requirements. Please check the exact dimensions and weights of cargo baskets with an OEG representative before ordering as our CCU design types undergo continuous improvement modifications. In addition, our range of cargo baskets available from our US Gulf of Mexico and Mexican bases meet the requirements of SEPco document OPS0055 and AECCA Gulf of Mexico standards.

Request for a quoteResults for

Check weight - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Handling - Machines & Equipment (6)

- Packing and packaging - machinery and equipment (6)

- Weight and mass - measurement and regulation instruments (4)

- Weighing and dosing equipment (3)

- Measurement and control instruments (2)

- Cooling and lubrication pumps (1)

- Drilling - machine tools (1)

- Food packaging (1)

- Offshore services (1)