- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramic slide rings

Results for

Ceramic slide rings - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

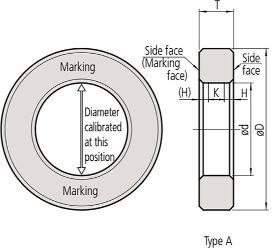

Innovacera developed a series of ceramic accessories for Inside Micrometers, Holtest and Dial Bore Gages. The ceramic material used mostly is zirconia. The zirconia ceramic setting ring advantages: Used for quick and accurate setting of dial bore gages, Holtest, and inside micrometers. If a setting ring of an optimal size is prepared, it can be used for calibration. Actual inside diameter is marked on each ring No more anticorrosion treatment is required when handling Ceramic Setting Rings normally, resulting in simple maintenance and storage. The Zirconia Ceramic Ring Gauges tolerance: Tolerance between the nominal size and the actual diameter: 0.001mm for 1-45mm DIA. setting rings Cylindricity: 0.001mm for 1-45mm DIA. setting rings Some Zirconia Ceramic Ring Gauges Innovacera made: 9mm, 10mm, 18mm, 20mm, 24mm, 25mm, 28mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic ring in aluminum oxide ceramics for the military,medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization. Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic Square Ring: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Ceramic Square Ring Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Square Ring Applications: 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera developed a series of ceramic accessories for Inside Micrometers, Holtest and Dial Bore Gages. The ceramic material used mostly is zirconia. The zirconia ceramic setting ring advantages: High wear resistance and long service life The coefficient of thermal expansion is very small, the effect of temperature is very small The hardness is very high, there is no need to worry about surface scars. Ring gauge management is simple (regular inspection interval is long, saving cost). The Zirconia Ceramic Ring Gauges Technology: Surface Roughness: Not more than Ra0.1um Straight Angle: 0.05/φ100 Parallelism: Not more than0.015mm Each 0.5mm as one size, from 1mm to 50mm. Some Zirconia Ceramic Ring Gauges Innovacera made and size detail: 9mm, 10mm, 18mm, 20mm, 24mm, 25mm, 28mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Laser Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters: 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Abrasion resistance/Zirconia ceramic ring for sealed ink cup/pad printing/innovacera 1. Introduction: Round Zirconia ceramic ring is used for a Ever Bright pad printing ink cup machine, electronic control, lighting and electrical temperature control and other industries.Zirconia ceramic scraper ring is also used for thermostat,technical ceramic,temperature control. The temperature controllers,manufactured with Zirconia,have revolutionary breakthrough if compared with traditional plastic parts.They are highly improved in strength,insulation performance,heat resistant performance,especially sensitivity to temperature Innovacera is offered Yttria Tetragonal Zirconia Polycrystal(Y-TZP), there are many applications of Zirconia ceramics in the chemical and petrochemical industries. They provide economic payback in the way of reduced maintenance and down time. Zirconia ceramics is also becoming the material of choice for components in healthcare applications.

Request for a quoteResults for

Ceramic slide rings - Import exportNumber of results

12 ProductsCountries

Company type

Category