- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramic metallization

Results for

Ceramic metallization - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

In a development that could have a significant impact on the electronics industry, the latest ceramic metallized insulators are making strides in enhancing semiconductor packaging and related applications. These insulators offer a range of practical benefits that can improve the performance and durability of electronic components. Let’s take a closer look at what sets them apart: Key Features of Ceramic Metallized Insulators: 1. Stability and Strength: The ceramic material employed in these insulators boasts an even texture, ensuring every batch maintains stable quality and flexural strength. This consistency in material quality is pivotal for the reliability of electronic components. 2.Dense and Weldable Metal Layer: The metal layers in these insulators are densely applied, providing a smooth and even surface. This not only enhances their appearance but also makes them easy to work with, particularly in manufacturing processes.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera supplies precision metallized ceramic components in aluminum oxide ceramics for the military, medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.

Request for a quote

UDEN-UKRAINE

Ukraine

(UDEN-S wall heaters are an excellent choice for autonomous or additional heating of any standard premises: apartments, houses, budgetary institutions or commercial real estate): ○ Metal-ceramic design heater UDEN-1000 (Energy-efficient metal-ceramic heaters UDEN-S are used to heat a variety of rooms: apartments, private homes, commercial real estate, and social spheres)

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic parts in aluminum oxide ceramics for the medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization.Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin) Available Ceramic Composition >94%,96%,99%,99.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DBC (Direct Bonded Copper) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,high thermal conductivity, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for "chip on boaed" technology which repre-sents the packaging trend in century. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing /Innovacera Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Metallized Ceramic Componenets: Innovacera supplies precision metallized ceramic ring in aluminum oxide ceramics for the military,medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization. Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher. Advantages of Ceramic-to-Metal Seals * More solid, durable hermetic seal and better electrical insulation * Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments * High mechanical strength, less fracture when applied to high vibration and high g-load conditions * Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera manufactures many kinds of metalized ceramic coil bodies for electrical inductors, including the H-shapes, U shape and Bone-shaped and so on. The main material of metalized ceramic coil bodies is 96 Alumina and the metallized coating material is W, Ni, Au etc. Our factory have more than 20 years of metalized ceramics producing experiences, can give a prompt solution for R&D project. The metalized bodies is partially metalized , ceramic inductor coil bodies cores can make very small size which it is big helpful for the electrical systems , wire-winding technique, electronics devices and electrical coils components miniaturization developed.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic-to-Metal Seal The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher.

Request for a quote

HOMESHOP

Poland

Liquid for disinfecting hands and surfaces, materials, equipment with a virucidal effect. Product for cleaning metal, laminated, glass, ceramic surfaces, door handles, handrails, handles, office equipment, mobile phones, payment terminals, etc.

Request for a quote

HOMESHOP

Poland

Liquid for disinfecting hands and surfaces, materials, equipment with a virucidal effect. Product for cleaning metal, laminated, glass, ceramic surfaces, door handles, handrails, handles, office equipment, mobile phones, payment terminals, etc.

Request for a quote

DEJA LTD.

Bulgaria

Screen printing is a printing technology, also known as serigraphy. Derived from two Greek words - seri (sieve) and graphos (write). Printing done with a considerable thickness of the layer of ink on fabric, synthetic material, paper, cardboard, plastic, glass, leather ceramic, metal and other materials. The shape of the host surface can be flat and irregular. Characteristic of this technology is the high ink coverage, enabling inscription in dark souvenir with a lighter color. Modern technology in screen printing provide sufficient quality of the print. In screen printing on textiles, the most commonly used inks are plastisol. Characterized by excellent stability and a large range of different colors. Used for printing on synthetic (polyester) and natural materials. Resistant to wash (40 °C) (50 °C) (60 °C). Should not be subjected to dry cleaning, ironing or washing at high temperatures

Request for a quote

DEJA LTD.

Bulgaria

UV digital printing on souvenir is a unique solution for high-quality printing on different surfaces as well as other applications for advertising miniature text, bright and solid colors. Direct printing is a technology where the print is happening directly from the client's file over the objects. The ink is transferred directly onto different surfaces such as plexiglass, glass, plastics, papers, self-adhesive film, PVC film, comatex, veralit, leather, textile, canvas, wood, ceramics and metal. The bigest advantage of this technology is the multicolor printing on small quantities, personalisation and advantage over dark surfaces and mirror printing over transperеnt materials.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin:China Product Name:Tungsten Powder Chemical Composition:99.99%Pure Tungsten Powder Lead time:15days Port of shipment:Xiamen Payment term:T/T,L/C Application 1 For high proportion alloy, green bullets, alloy steel, drill, and products; 2 High-active nano powder can be used as the raw materials of high performance proportion alloy additive quantity (powder from 30% ~ 50%) and preparation of the silk road, and raw materials can be used as additive, high alloy materials, tungsten powder can significantly improve performance and reduce alloy sintering temperature and shorten the production cost saving time and sintering; 3 The nanometer powder can be used as the raw material, nanometer WC preparation of nanocrystalline cemented carbides. Due to the special nanometer powder, and can be used for pore structure ceramic metallization coating W-Mn method of tungsten powder materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WMC SINTERSTAR AG

Switzerland

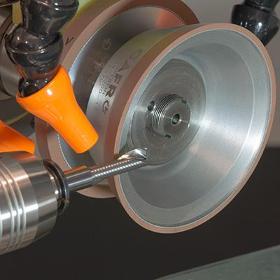

WMC Sinterstar AG represents the company Mirka (Cafro) in Switzerland. Cafro diamond and CBN grinding wheels are characterised by innovative bonds and high cutting ability for machining hard metal, ceramics and steel. Cafro's core competence is the production of resin bonded diamond and CBN grinding wheels. Over the years, the company has also specialised in the manufacture of metal-, hybrid-, ceramic-bonded and electroplated grinding wheels and PCD/PCBN tools. Our employees will also find the optimal grinding solution for your company. We benefit from our own knowledge and experience as a carbide manufacturer.

Request for a quote

NORELEM FRANCE

France

Version: Ground. Top face without centerbore. Note: Rest pads can also be used as feet for jigs and fixtures. Advantages: Cerazur is extremely impact and bend resistant. The basis of this material is zirconium oxide. It is a composite metal-ceramic material.

Request for a quote

FERPLAST SNC

Italy

The gluing of the professional range EG have powers from 220 to 400 W with high extrusion capacity (from 1400 to 2200 g/h) They have a high reliability, even in case of intensive use. They work with all sticks with a diameter of 12 mm, Length 200-300 mm. and are suitable for the bonding of wood, cardboard, leather, metals, fabric, glass, ceramic, plastic, etc. The progress of glue takes place through the mechanical trigger. Professional models of EG series are equipped with ON / OFF switch and a potentiometer for adjusting the temperature up to 220-230°C.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

OKS 1105 prevents the formation of electrically conductive layers and minimises the risk of flashovers and dielectric losses. The insulators and switchgear covered with the paste thus maintain a good insulation resistance. Sealing lubrication for electrical or electronic equipment such as relays, plug-in connections, cable lugs and lamp sockets Protection of insulators and switchgear in humid atmospheres, for example of junction boxes, screw terminals, overload cutouts at high-voltage pylons, connecting cables and terminal connections Lubricant for plastic screw connections and other moving parts of metal, ceramic, plastic Advantages and benefits Excellent water repellent properties Excellent surface wetting Good adhesion on glass, porcelain and plastics Stable consistency across a wide temperature range Very good resistance to chemical and weather-based influences (e.g. ozone, UV radiation) Neutral with regard to many materials

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Sliding coating of materials of all kinds, such as metals, glass, ceramic, wood, leather and plastics As lubricant for threads of all kinds, such as machine screws, thread-cutting screws, sheet-metal and wood screws for increasing pre-tension forces or reducing screw-in torques As dry lubricant for maintenance and care of plastic/metal sliding pairs For assembly of axial face seals or dry lubrication in textile or paper-processing machines Advantages and benefits Highly effective due to outstanding film-forming properties Broad range of uses for dry lubrication in maintenance and care Waterproof and resistant to weathering

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Sliding coating of materials of all kinds, such as metals, glass, ceramic, wood, leather and plastics As lubricant for threads of all kinds, such as machine screws, thread-cutting screws, sheet-metal and wood screws for increasing pre-tension forces or reducing screw-in torques As dry lubricant for maintenance and care of plastic/metal sliding pairs For assembly of axial face seals or dry lubrication in textile or paper-processing machines Advantages and benefits Highly effective due to outstanding film-forming properties Broad range of uses for dry lubrication in maintenance and care Waterproof and resistant to weathering

Request for a quote

EVRICA FURNITURE

Bulgaria

Another piece of garden furniture that is sure to decorate your yard. When it comes to garden furniture, the choice is not limited to beautiful flowers, fence layout, comfortable benches and picturesque gazebos. To ensure the necessary convenience and comfort, it is best to bet on a wrought iron garden table. It will be a perfect addition to the interior of your garden, and also, it will be another beautiful thing that pleases the eye, and not just purely practical to use. The advantages of this furniture are really many. And they are not only related to the opportunity to enjoy the beautiful landscape in your garden, sitting comfortably next to it The proposed model wrought iron garden table is a combination of a comfortable ceramic top, with a solid metal stand and elegant legs. The line is clean, and the model has a number of advantages — it is simple, with a sleek and fine design, a sturdy and comfortable top that further creates a sense of resilience.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Degreasing all surfaces and parts of non-absorbent materials, e.g. metals, ceramic or plastics and elastomers Cleaning of adhesive surfaces for coatings, paints or adhesives and sealants Cleaning of friction surfaces on which high friction forces are transmitted such as clutch and brake linings (brake cleaners) Removal of aged and gummy oil and grease residues, of residues of brake fluids and silicones, as well as of residues of simple coatings, adhesives and sealants Advantages and benefits Highly effective due to actively cleaning substances Modern cleaner on a solvent base Fast and residue-free evaporation of the cleaner

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Degreasing all surfaces and parts of non-absorbent materials, e.g. metals, ceramic or plastics and elastomers Cleaning of adhesive surfaces for coatings, paints or adhesives and sealants Cleaning of friction surfaces on which high friction forces are transmitted such as clutch and brake linings (brake cleaners) Removal of aged and gummy oil and grease residues, of residues of brake fluids and silicones, as well as of residues of simple coatings, adhesives and sealants Advantages and benefits Highly effective due to actively cleaning substances Modern cleaner on a solvent base Fast and residue-free evaporation of the cleaner OKS 2660 is suitable for use with the OKS Airspray system Also available as spray version OKS 2661

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Degreasing all surfaces and parts of non-absorbent materials, e.g. metals, ceramic or plastics and elastomers Cleaning of adhesive surfaces for coatings, paints or adhesives and sealants Cleaning of friction surfaces on which high friction forces are transmitted such as clutch and brake linings (brake cleaners) Removal of aged and gummy oil and grease residues, of residues of brake fluids and silicones, as well as of residues of simple coatings, adhesives and sealants Advantages and benefits Modern active cleaner on the basis of a solvent mixture Highly effective due to actively cleaning substances Better initial dissolving of soiling than at brake cleaners thanks to longer soaking-in period No formation of condensate on the material surface OKS 2610 is suitable for use with the OKS Airspray system Also available as spray version OKS 2611 (propellant gas CO2)

Request for a quote

GRÜNING & LOSKE GMBH

Germany

lastic and strong adhesive and sealant on polyurethane (PUR) basis. For bondings and sealings on metals, many plastics, ceramic, wood, glass, stone, etc.. Applications: Tank and apparatus construction, Car body, freight container and vehicle construction, Ventilation and air conditioning, Pipeline and fittings construction, Energy and electrical industry, Insulating technology and in many areas of plastic technology and wherever silicone is not suitable. Properties: Can be painted over and sanded after curing, Odourless curing, Resistant to weathering and UV, Excellent aging resistance, Resistant to fresh water and saltwater, Stable, pasty and Silicone-free. A better adhesion is achieved by using suitable WEICON adhesion agents. With suitable paint coating systems (except alkyd resin paints). Available in white, grey and black.

Request for a quoteResults for

Ceramic metallization - Import exportNumber of results

142 ProductsCountries

Company type

Category

- Ceramics (31)

- Ceramics, industrial (16)

- Silicones (11)

- Moulds, ceramics (9)

- Ceramics, refractory (6)

- Surface treatment - machinery and equipment (6)

- Cleaning and maintenance - equipment and supplies (4)

- Electricity generators (4)

- Compactors and crushers (3)

- Aluminium coatings (2)

- Ceramic, components - electric (2)

- Chemistry, inorganic - raw materials and derivatives (2)

- Cleaning and maintenance products, household (2)

- Coating machinery (2)

- Electric and electronic components - machines for manufacturing (2)

- Grinding - machine tools (2)

- Laser - cutting and welding machines (2)

- Marking - diverse products (2)

- Measurement - Equipment & Instruments (2)

- Painting and varnishing of rubber and plastic (2)