- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cement aggregates

Results for

Cement aggregates - Import export

PI MAKINA

Turkey

Cone crushers are designed to crush hard and a corrosive brook and quarry materials such as granite, basalt, and andesite. It is used as a secondary and tertiary crusher. The maximum input size is 135-215 mm. The principle of operation of cone crushers is to crush the materials with the effect of compression, cutting and bending. It offers low dust and wear-out rates as they crush the material through compression. Thanks to the long-lasting wearing parts, the crushing process lasts longer. By virtue of its advanced crusher chamber design, it provides high productivity with less wear on parts. The adjustable crusher chamber makes it possible to receive material of the desired size. In addition, operating costs are low as maintenance and repair operations can be easily carried out on the crusher.

Request for a quote

UMMANMAK

Turkey

UMMAN Concrete Recycling System aims to recycle the waste concrete formed in the concrete plant by washing the aggregate and cement so that it can be used in the concrete plant again. The Concrete Recycling Unit recycles the waste concrete, providing great benefits in terms of cost and preventing environmental pollution. ENVIRONMENTALLY FRIENDLY In our period when the protection of the environment is much more important, minimizing the environmental impact and producing harmless to the nature have become a necessity for concrete production plant. Waste concrete left to nature freezes, pollutes underground resources and harms the environment and living things by adversely affecting groundwater. The Recycling Unit is of great benefit to the environment as it recycles the waste concrete into production.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH has the second largest range of elevator buckets. With more than 400 bucket types and sizes, we have a bucket for every product and application. Elevator buckets in regular & stainless steel (deep drawn or welded) Synthetic elevator buckets (nylon, HDP or polyurethane) Elevator buckets for agricultural applications (e.g. grain, seed, mixed feed, sugar) Elevator buckets for industrial applications (e.g. cement, gypsum, aggregates, coal, artificial fertiliser)

Request for a quote

CONVERGENT GROUP

Belgium

Pentra-Sil® (C&N) cleans and neutralizes concrete that suffers from efflorescence, sweating, and other alkalinity problems. Pentra-Sil®(C&N) Lithium fixer for Concrete Efflorescence and Sweating Problems works by infusing lithium ions into the substrate—these ions calm alkali reactions between aggregate and Portland cement thereby reducing the formation of alkali salts and sweating. (For serious problems we recommend a full treatment of Pentra-Sil® (C&N), Pentra-Sil® AC), and Pentra-Sil®(HD). Pentra-Sil®(C&N is also excellent for cleaning concrete after diamond polishing.Pentra-Sil®(C&N) removes fine particles and dust that can reduce shine.

Request for a quote

INOTEK MAKINA

Turkey

CSTC Type Screw conveyor is a mechanism that uses rotating helical screw blade coiled around a shaft, it conveys differnt types of powder or granules material. It is cost-effective. They are genarally used for coal, ash, slag, cement, wood chips, aggregates, cereal grains, an,mal feed, boiler ash, meat and bone meal, municipal solid waste, and so on....

Request for a quote

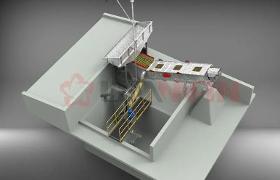

BEYAZLI GROUP

Turkey

Concrete Batching Plant - Ready Mix Concrete Plant - Concrete Machinery - Concrete Mixer - Concrete Factory |More Economic | Advanced Technology | More Durable | Fast Delivery| Campaign Price: 170.370 EURO (free installation and free staff training) Contact: seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 100 m³ / Hour ready-mix concrete /8 HOURS Transportation : 5 HQ 40' Containers Concrete Batch Plant Ready Mixing Concrete Plant Concrete Mix Machinery Concrete Transportation | More Economic | Advanced Technology | More Durable | Fast Delivery The ready-mix concrete plant or concrete batching plant is designed with a fully automatic operating system. Designed to work 24 hours. This concrete batching plant system is made to produce ready-mix concrete from the mixture of Aggregate, Cement, Water and Concrete additives with specific ratio. The system of concrete batching plant starts operation with the dosage. Video: https://www.youtube.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cement aggregates - Import exportNumber of results

6 ProductsCountries

Company type