- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- catheter tubing

Results for

Catheter tubing - Import export

PEEKCHINA CO., LTD.

China

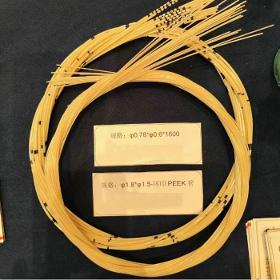

What is PEEK Catheter Tubing? Polyether ether-ketone (PEEK) is a thermoplastic polymer that can be extruded into catheter tubing with desirable properties such as high tensile strength, buckling resistance, good pushability and radiopacity. Why would you choose PEEK medical Tubing? Unlike polyimide, PEEK is melt processable and can be extruded into small diameter tubes for vascular catheters and larger diameter, thin wall tubes for non-vascular applications, such as Natural Orifice Transluminal Endoscopic Surgery (NOTES) devices. What medical devices or procedures is PEEK commonly used in? PEEK vascular catheters provide strong and flexible, small diameter tubing. Non-vascular applications such as endoscopic and laparoscopic procedures often demand larger diameter, thinner wall PEEK tubes.

Request for a quote

PEEKCHINA CO., LTD.

China

Our black PEEK tubing is the perfect solution for medical devices, offering excellent biocompatibility, durability, and resistance to high temperatures, chemicals, and radiation. Made from high-quality polyetheretherketone (PEEK) material, our tubing is reliable and versatile, making it ideal for a wide range of applications. Our black PEEK tubing is available in custom sizes to meet your specific needs. Choose our black PEEK tubing for your next project and experience the benefits of high-quality tubing that meets your exact specifications. Whether you're looking for tubing for catheters, surgical instruments, or other medical devices, our black PEEK tubing is a reliable and durable solution that you can count on.

Request for a quote

AXON CABLE SAS

France

Axon' expertise in PTFE insulated wires and cables has enabled the company to offer different PTFE based products : tubes, rods, profiles, films, glass cloth impregnated with PTFE, desiccant bags, Celloflon® tapes, etc... They all take advantage of the mechanical, chemical, thermal and electrical characteristics of the PTFE (polytetrafluorethylen). Celloflon is an expanded PTFE material patented by AXON'CABLE Advantages Good temperature resistance (-200°C to +260°C) Low dielectric constant Non adhesive properties Non flammability Chemical resistance, … Biocompatibility Construction Tubes can be used as cable insulation, cannulae, tubes for liquids or hot gases (e.g assemblies for ink jet printing). Various versions : from ultra thin tubes to tubes with specific diameters Various colours : natural, black, yellow, red, orange, bicolour, spiral, … Tubes for micro-catheters with walls as thin as 10 µm PTFE multilumen tubing

Request for a quote

AXON CABLE SAS

France

Axon' expertise in PTFE insulated wires and cables has enabled the company to offer different PTFE based products : tubes, rods, profiles, films, glass cloth impregnated with PTFE, desiccant bags, Celloflon® tapes, etc... They all take advantage of the mechanical, chemical, thermal and electrical characteristics of the PTFE (polytetrafluorethylen). Celloflon® is an expanded PTFE material patented by AXON'CABLE Advantages Good temperature resistance (-200°C to +260°C) Low dielectric constant Non adhesive properties Non flammability Chemical resistance, … Biocompatibility Construction Tubes can be used as cable insulation, cannulae, tubes for liquids or hot gases (e.g assemblies for ink jet printing). Various versions : from ultra thin tubes to tubes with specific diameters Various colours : natural, black, yellow, red, orange, bicolour, spiral, … Tubes for micro-catheters with walls as thin as 10 µm PTFE multilumen tubing Axon' offers a wide range of rods specially used as fillers. They are made with PTFE or celloflon® (porous PTFE).

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

An internationally active medical technology company that produces and sells catheter tubes, among other things, has optimized its manufacturing process with the help of a production line from Metzner Maschinenbau. With Metzner's know-how, it was possible to replace a costly manual process with an automatic machine, saving costs. At the same time, the length accuracy and the cutting quality were significantly improved. The company supplied a fully automatic system that precisely cuts the catheter tubing to length, removes the mandrel present from the extrusion without leaving any residue and without longitudinal expansion, and then deposits the tubing in a collecting container at the end. Processing with exact length accuracy and mandrel removal The Metzner special development cuts catheter tubes to an exact length and removes the mandrel inside safely and precisely. The finished material is deposited in a collection container.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Silicone Molding Liquid Silicone Rubber (LSR) and Silicone Transfer Molding (STM) are widely used in the medical device industry for the production of various medical device components such as catheters, tubing, connectors and handles or grips. The process of LSR molding involves injecting liquid silicone rubber into a mold cavity, often over electrical connections or a circuit board. It is then allowed to cure or solidify into the desired shape.

Request for a quote

OCTAMED SAGLIK URUNLERI SAN. VE TIC. A.S.

Turkey

Constructed from non-stretch transparent polyethylene film. Ideal for wound sites require frequent visual checks. It allows flexibility and comfort around the wound for easier movement and adjusts diagonally and horizontally for swelling. Used for many different applications such as fastening tubing and devices such as catheters and IV tubing, stabilization of finger splints. Specifications / Key Features: Easy, straight, bidirectional tear for customize sizing Porous for breathability Easy to handle with gloves Good adhesive to skin and tubing for securement Water-resistant Hypoallergenic X-Ray Permeable Leaving minimal adhesive residue upon removal Non- Sterile

Request for a quote

AKOVA VERTRETUNG&BERATUNG

Turkey

Intragastric balloon placement is a weight-loss procedure that involves placing a saline-filled silicone balloon in your stomach. This helps you lose weight by limiting how much you can eat and making you feel fuller faster. The intragastric balloon procedure is done in the endoscopy unit as an outpatient procedure. You'll be sedated for the procedure. During the procedure, the doctor advances a thin tube (catheter) loaded with the intragastric balloon down your throat into your stomach. Next, the doctor advances an endoscope — a flexible tube with a camera attached — down your throat into your stomach. The camera allows your doctor to see the balloon as he or she fills it with saline. The procedure takes about a half-hour. You can normally go home one to two hours after the procedure is finished.

Request for a quoteResults for

Catheter tubing - Import exportNumber of results

9 ProductsCompany type

Category