- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cartridge seals

Results for

Cartridge seals - Import export

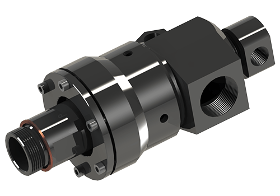

KROMA LTD

Serbia

Cartridge mechanical seals manufactured to meet API 682 (ISO21049) are meant for use in the petroleum, natural gas and chemical industries. During processing of crude oil various chemical compounds are being released, and designers should count on sealing fluids which could be: -under the very high pressure -under very high or very low temperatures -on very high or low pH value -very high or very low viscosity -abrasive -harmful, polluting and potentially explosive API 682 (ISO21049) specifies requirements and gives recommendations for sealing systems with aim to secure that the fluids with characteristics above could be transported: -with minimum waste -with maximum environmental protection -with minimum mechanical failure -with best price-quality ratio

Request for a quote

KROMA LTD

Serbia

Cartridge mechanical seal single or double type, with our without flush, with our without lip seal. Seals are for application in demanding conditions such as pulp and paper industry, mining industry, various stages in the oil and gas industry, etc.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square cartridge heaters are used where much power has to be installed near the surface of a tool, e.g. in cutting knives, sealing stations or hot plates. With a soft, malleable condition in stainless steel or nickel sheath square cartridge heaters can easily be pressed into common milled rectangular grooves. Apart from the advantageous heat transfer over ¾ of the sheath, it is not necessary to cement or cast in the heater which is imperative for round cartridge heaters. Unlike tubular heaters which are also available in square sections (see chapter Flexible Heating Pipes), the square cartridge heaters have the termination on one side and can be loaded with 16W/cm² (2.5W/in²) due to their special inside construction.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Aluminum cartridges protect the sealing compound with a diaphragm and seamed lid to prevent leakage, ensuring a long shelf life and preventing the contents from drying out. The two-component integrated system is suitable for fast-curing fillings and easily used with existing guns on the market while offering a variety of static mixer nozzles. Cartridges can be printed with customized art in up to six colors and have lacquer applied to the inside surfaces. Products include cartridges and a two-component integrated system.

Request for a quote

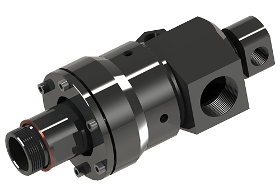

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite. For coking heat transfer oil with temperature higher than 230 °CVersion HT with diamondhard sealface and hightemperature graphitesealring solid grease ballbearingsmaintenance free no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar heat transfer oil air TEMPERATURE MAXIMUM 300 °C heat transfer oil air SPEED MAXIMUM 700 1/min ISO 228 thread 700 1/min NPT thread SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite ballbearings (can be relubricated) no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar heat transfer oil air 10,0 bar steam 17,0 bar water TEMPERATURE MAXIMUM 190 °C water steam heat transfer oil air SPEED MAXIMUM 700 1/min NPT thread 1500 1/min ISO 228 thread SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2")

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Fast delivery of spare and wear parts We have a modern shelf stock of all common wear and spare parts. The delivery guarantee from our own stock is a matter of course for us - as well as for older machines and third-party products. ▪ Blasting gloves/sandblasting gloves ▪ Blasting nozzles/sandblasting nozzles ▪ Clamps ▪ Vent valves ▪ Laminated glass panes ▪ Profile seals ▪ Illumination panes ▪ Filter cartridges ▪ Replacement diaphragms ▪ Sealing rings ▪ Nozzle holder ▪ Blasting hoses/sandblasting hoses ▪ Door seals ▪ Air nozzles ▪ Check valves ▪ Sinter filters ▪ Metering rings ▪ baffle discs and much more.

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite. For coking heat transfer oil with temperature higher than 230 °CVersion HT with diamondhard sealface and hightemperature graphitesealring graphite bushbearingsmaintenance free no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar heat transfer oil air 12,0 bar steam 17,0 bar water TEMPERATURE MAXIMUM 175 °C air 190 °C steam 300 °C water heat transfer oil SPEED MAXIMUM 700 1/min ISO 228 thread 700 1/min NPT thread SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2")

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 554 2/2-way angle seat globe valve has a plastic piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing or a compact seal cartridge, dependent on the size and version. A wiper ring or the wiper contour of the seal cartridge additionally protects the valve spindle against contamination and damage. This provides low maintenance and reliable spindle sealing even after a long service life. —Simple and fast commissioning —Good flow capability and compact design —Valve and positioner are optimally adapted to each other. (For positioner details please refer to the relevant data sheets) —Optionally suitable for contact with food according to Regulation (EC) No. 1935/2004 (K-No. 1935) —Standard gland packing suitable for vacuum up to 20 mbar (abs.)

Request for a quote

OMEGA AIR

Slovenia

WOSm water oil separators have been developed to separate lubricant oil from condensate generated in compressed air systems. Due to patented technology regular service can be done in 30 seconds without any cleaning. Separation begins in “cyclonic depressurization chamber” and continues in “filter cartridge”. When the “filter cartridge” is fully saturated you just simply unscrew complete cartridge and replace it with new one. All the condensate stays in old cartridge which can also be sealed with plastic cover and disposed according to local directives and laws.

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Repair Kits Related Links DM Advantage Training Online Catalog QuickShip Program Literature Order Center Video Library Related Products DM Advantage Two-Speed Fan Drives PolarForce Two-Speed Conversion Kits DM Advantage Reman Fan Drives DM Advantage Repair Kits WindMaster Fans WM Revolution Fans WindShift Modular Fans To maximize DM Advantage's performance, depend on DM Advantage Repair Kits. Designed to handle the demanding high-torque, high-heat requirements of today's more powerful diesels, these parts ensure top vehicle performance, unrivaled fuel efficiency, and savings you'll see on your bottom line. DM Advantage Super Kits include a fan mounting disc, clutch pak, sheave bearing, O-rings, friction liner, air cartridge, face seal, retaining rings, facing screws and lubricant. These kits allow the rebuilding of a DM Advantage to new condition in about 30-45 minutes. DM Advantage Seal Kits include everything you need to eliminate an air leak in fifteen minutes: O-rings, retaining rings, facing screws, air cartridge, face seal and lubricant. DM Advantage Friction Disc Kits include a fan-mounting disc, friction liner and facing screws — allowing the replacement of a worn-out disc and liner in fifteen minutes. DM Advantage Friction Liner Kits include a friction liner and facing screws. Liner replacement can be completed in about fifteen minutes. All Horton Repair Kits feature Genuine Horton Parts. DM Advantage Bearing Kits include a sheave bearing, bearing nut and retaining ring. Bearing kits are designed for repairs requiring fewer parts than a super kit. DM Advantage Clutch Pack Kits include an O-ring lubricant, facing screws, air cartridge seal, spring housing/piston. Clutch Pack Kits repair the clutch pack. PolarForce Two-Speed Conversion Kits include an O-ring seal, fan mounting disc, button head screws, air chamber seal, face seal, retaining ring, friction liner, spring housing/piston, magnet assemblies. Whether you're looking to upgrade your fleet's performance or needing torque enough to turn today's 32-inch diameter fans, DM Advantage is the answer. Related Products - DM Advantage On/Off Fan Drives - DM Advantage Reman On/Off Fan Drives - DM Advantage Two-Speed Fan Drives - DM Advantage Reman Two-Speed Fan Drives - PolarForce Two-Speed Conversion Kits - WindMaster Fans - WindMaster Revolution Fans - WindShift Fans - Shogun Fans Links - DM Advantage Training - Order or View Literature - On-line Catalog

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Conversion Super Kit Related Links Online Catalog QuickShip Program Literature Order Center Video Library Related Products DM Advantage Two-Speed Fan Drives PolarForce Two-Speed Conversion Kits DM Advantage Reman Fan Drives DM Advantage Repair Kits WindMaster Fans WM Revolution Fans WindShift Modular Fans Featuring superior components, the DM Advantage Conversion Super Kit converts a standard DriveMaster® On/Off Fan Drive to a DM Advantage On/Off Fan Drive. The kit is easy to install and includes a premium double row angular contact (DRAC) sheave bearing, an improved air cartridge seal that provide 40 percent longer life, and a long-wearing friction liner for added reliability and reduced maintenance. Like all Genuine Horton Super Kits, these kits contain everything needed to completely rebuild your fan drive. Once converted, the DM Advantage On/Off Fan Drive has the latest innovations and a fail-safe design for long-life performance. Benefits - High-performance and efficient engine cooling - Increased reliability in high-horsepower applications - Easy to install and maintain Features - The latest innovations - A premium double row angular contact (DRAC) sheave bearing - Improved air cartridge seal - Long wearing friction liner Applications - Heavy-duty trucks - Medium-duty trucks - Buses - Off-highway equipment Premium Bearing vs. Groove Hub Bearing Related Products - DM Advantage On/Off Fan Drives - DM Advantage Two-Speed Fan Drives - PolarForce Two-Speed Conversion Kits - WindMaster Plastic Fans - WindMaster Revolution High-efficiency, Hybrid-flow Fans - WindShift Modular Fans Links - DM Advantage Training - Order or View Literature - On-line Catalog

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

HT/S Advantage™ / PolarExtreme Reman Fan Drives & HT Now there's a superior alternative to upgrading an HT/S Advantage or S Fan Drive that endures the harshest environments: PolarExtreme Repair Kits. PolarExtreme Repair Kits feature seal components constructed from hydrogenated buna nitrile rubber (HBNR) to enhance the Horton fan drive for extreme conditions. The PolarExtreme super Kit includes the new PFD (Piston Friction Disc) with a unique fin design for better heat dissipation. These kits mean PolarExtreme delivers the ultimate upgrade with: - Longer life - Better abrasion resistance - 30% greater tolerance to temperature extremes - Less likely to suffer spiral fatigue - Less breakage and leakage Horton blue seals identify these kits as the extreme performer — PolarExtreme. PolarExtreme Seal Kit Repairs and upgrades Horton HT/S Advantage and S Air-Engaged Fan Drives Blue D- & O-ring, cartridge assembly, face seal assembly, System Sentry®, umbrella check valve, spline lubricant, spline lubricant brush, socket head screws. PolarExtreme Super Kit Repairs and upgrades Horton HT/S Advantage Air-Engaged Fan Drives PolarExtreme PFD (Piston Friction Disc) with a unique fin design for better heat dissipation, hub assembly, sheave bearings, friction facing, lock nut, blue PolarExtreme D- & O-ring, cartridge assembly, face seal assembly, System Sentry, umbrella check valve, spline lubricant, spline lubricant brush, socket head screws. Related Products - HT/S Advantage Air-Engaged Fan Drives - Advantage Reman Fan Drives & Genuine Horton Repair Kits Links - Order or View Literature - On-line Catalog

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Air-Engaged Fan Drives The HT/S Advantage is perfect for high run time applications. We started with a technologically advanced hub bearing assembly optimized for durability. We added a PFD (Piston Friction Disc) featuring the System Sentry®. This patented device reacts to heat build up caused by fan drive slippage or fan obstructions. When it senses excessive heat, the System Sentry releases, disengaging the fan drive before extensive damage occurs to the cooling system. Finally, we included a new air cartridge with a long-life carbon tip and double O-ring air seal to reduce the possibility of air leaks. The bearing assembly design, PFD with System Sentry, and air cartridge, combine to provide you with a premium on/off fan drive that will perform consistently under extreme conditions - exactly the sort of performance you've come to expect from Horton! Benefits - Long service life - Ideal for harsh environments - Consistent performance - Better protection against heat damage Features - System Sentry - Long-life air cartridge - Double O-ring air seal Applications - Heavy-duty trucks Related Products - Advantage Reman Fan Drives & Genuine Horton Repair Kits - HT/S PolarExtreme Reman Fan Drives & HT/S or S Repair Kits - WindMaster Fans - HG300 Solenoid Valves Links - Order or View Literature - On-line Catalog - HT/S Advantage Training Manual

Request for a quote

SOMEFLU

France

Horizontal process non-metallic free-flow pump equipped with mechanical seal Fully suitable for corrosive liquids or fluids with thick particles Recessed impeller with straight blades and tangential discharge section Designing according to NFE 44121- DIN 24256 - ISO 2858 - ISO 5199 Suction and discharge line according to NFE 29-203 – DIN 2533 – ISO PN16 All hydraulic parts are machined from thick parts of plastic (no injection moulding) Plastic used : PP, PVDF, PEHD The shaft sealing is an own SOMEFLU cartridge mechanical seal design Cartridge mechanical seal version : standard seal, injection, rinsing, grease filling or double seal For ATEX (explosion proof), antistatic plastics charged with black carbon are used Max flow : 180 m³/h Max delivery head : 35m

Request for a quote

SOMEFLU

France

Main applications Steel, Chemical, Mining, Environment Construction Horizontal process non-metallic pump equipped with mechanical seal Fully suitable for corrosive liquids or fluids with thick particles NP product with a recessed impeller For a free-flow version, please refere to our HV product Designing according to NFE 44121- DIN 24256 - ISO 2858 - ISO 5199 Suction and discharge line according to NFE 29-203 – DIN 2533 – ISO PN16 All hydraulic parts are machined from thick parts of plastic (no injection moulding) The shaft sealing is an own SOMEFLU cartridge mechanical seal design Cartridge mechanical seal version : standard, injection, rinsing, grease filling or double seal For ATEX (explosion proof), antistatic plastics charged with black carbon are used Materials PP, PVDF, PEHD, PE-UHMW, SOMEDUR® Performance data Max flow : 190 m³/h Max delivery head : 50m

Request for a quote

SOMEFLU

France

Horizontal process non-metallic pump equipped with mechanical seal Pumps are designed for heavy-duty use in the most severe conditions Designing according to NFE 44121- DIN 24256 - ISO 2858 - ISO 5199 Suction and discharge line according to NFE 29-203 – DIN 2533 – ISO PN16 All hydraulic parts are machined from thick parts of plastic (no injection moulding) Plastic used : PP, PVDF, PEHD, PFA, PTFE The shaft sealing is an own SOMEFLU cartridge mechanical seal design Cartridge mechanical seal version : standard seal, injection, rinsing, grease filling or double seal Available in mag-drive version, please see the NP-M product For ATEX (explosion proof), antistatic plastics charged with black carbon are used Max flow : 1500 m³/h Max delivery head : 90m

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cartridge seals - Import exportNumber of results

17 ProductsCountries

Company type