- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- calibrated gauges

Results for

Calibrated gauges - Import export

OR.P. STAMPI SRL

Italy

Highly advanced electronic inspection machinery, along with sensitive calibrated gauges, surface metering apparatuses are what complete our sophisticated metrology laboratory permitting OR.P.Stampi to be ISO 90012000 certified and to be synonymous of quality.

Request for a quote

ZETEK SP. Z O.O.

Poland

The certification of gauges is based on checking that the instrument maintains the prescribed measurement tolerances and MSA processes that confirm the stability of the measurement process of the gauge used in different conditions and by different people. Tests and control and measurement devices undergo the process of checking the current state, and then we carry out the calibration process and recertification. We carry out the certification and calibration process of the gauges in accordance with the procedures resulting from ISO 17025 , which confirms the credibility of our work. At the client's request, we perform work in accordance with the requirements and processes resulting from the individual features or parameters of a given measuring instrument. Calibration of the gauges Calibration is an integral part of the construction and production processes of control and measurement devices and gauges, and is also used during service or repair work.

Request for a quote

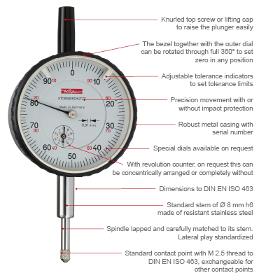

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The well thought-out design, accurate components and robust construction of our Precision Dial Gauge series offer reliability, durability and long working life. The standard features that enhance the quality across our entire product range are: Calibrations of all Dial Gauges are traceable to national and international standards. The final quality control for the whole series includes visual inspection and full mechanical functional tests. Supplied with Declaration of Conformity and Confirmation of Traceability. Materials and components selected specifically to ensure a long working life.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

To ensure that an instrument provides accurate measurements, regular calibrations are necessary. Calibration means to operate a target-performance comparision using a measuring instrument and a traceable reference. Calibration of instruments is essential in every area where sensitive measurement technology is used, e.g. in the manufacturing of sensors. It is the only way to guarantee quality standards and prevent defects arising in processes and products from the outset. For companies wanting to attain ISO 9001 certification, regular calibration of testing equipment is a requirement. halstrup-walcher has been accredited by the German calibration service DKD and Deutsche Akkreditierungsstelle GmbH (DAkkS) as a calibration laboratory in accordance with DIN EN ISO / IEC 17025 since 1999 – among other things for calibration of pressure measurements.

Request for a quote

BUDENBERG GAUGE CO LTD

United Kingdom

Fast response, exceptional repeatability and accuracy are just some of the standard features of our range of Bimetallic or Filled System Temperature Gauges. We have an extensive range of systems, options and configurations and can provide a cost effective solution to all your temperature measurement needs. Budenberg Gauge Co Ltd is a premier manufacturer of instrumentation for Chemical, Food and Beverage, Oil and Gas, Petrochemical, Pharmaceutical, Power Generation and Transmission, Refrigeration, Water and Waste Water markets. Quality and reliability have become the trademark of all Budenberg products and all our instruments are supplied with a minimum 1-year guarantee and carry a unique serial number for traceability purposes. Budenberg provides highly specialised machined - to complete products for niche industries globally. Our resources allow for bespoke solutions from finished product to machined components.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BUDENBERG GAUGE CO LTD

United Kingdom

Schaffer Diaphragm gauges are designed for use on slurries, viscous or corrosive fluids that would normally attack or block standard bourdon tube gauges. 316 Stainless Steel full safety pattern case. Implementing specialist materials for both the connection and diaphragm enable the Shaffer Diaphragm gauge to be configured for use on any gaseous or liquid media including suspended solids or powders. The direct drive from the diaphragm to the movement ensures a more positive indication of pressure than other models of tube gauges. Offering a full range of screwed connection sizes and materials, Schaffer Diaphragm gauges can operate at pressure ranges as low as 30 mBar with the option to permit units to withstand a maximum pressure of 70 bar.

Request for a quote

BLOWERDOOR GMBH

Germany

Maintain the high accuracy of your BlowerDoor measuring technology by regularly submitting it to a calibration. Benefit from the high accuracy of the BlowerDoor measuring technology: At ± 4% or rather ± 5% (flow rings D + E), the accuracy of the BlowerDoor testing flow rings – as well as that of the pressure gauge DG-700 (± 1%) or DG-1000 (± 0.9 %) – clearly exceed the minimum legal requirements. The manufacturer’s calibration as well as the calibration with DAkkS-certificate, are subject to the highest quality standards. When calibrated, all measuring systems undergo a preceding functional test. If required, we will gladly provide you with a replacement device at favorable rates and conditions, while your BlowerDoor measuring system is being calibrated or repaired.

Request for a quote

BUDENBERG GAUGE CO LTD

United Kingdom

The Classic range of Pressure Gauges has been designed to meet the high demands of the process industry. From harsh corrosive chemical applications to general engineering uses, the Classic combines a high specification with a very cost-effective price. The standard unit incorporates 316 stainless steel wetted parts that are housed within a liquid fillable 316 stainless steel case. Standard units are available as dual scale bar and psi but custom scales can be supplied. 316L wetted parts and cases are available as an option. Available with a wide range of accessories including: Syphons, Snubbers, Gauge Savers, Manifolds, Diaphragm Seals etc ensures that Budenberg can provide you with the right product to suit any individual application or requirement. Scale Ranges: 0 to 1 bar to 0 to 1400 bar or equivalent units of pressure / vacuum are available. Size: 100 mm (4”) & 150mm (6") Mounting: Direct, Flush or Surface

Request for a quoteResults for

Calibrated gauges - Import exportNumber of results

9 ProductsCountries

Company type