- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cabling machines

Results for

Cabling machines - Import export

SINC RECYCLING MACHINERY LTD.

Turkey

Mini Razzor 150 cable granulator is advanced-level cable and electronic waste recycling machine. With the compact design the machine becomes mobile, it can be easy moved to other locations and works like plug and play machine. The machine is equipped with all needed to work independent. Just supply the electricity and you can start to recycle your cable or electro waste for to separate the coper, metals, lead or other ferrous or nonferrous metals from the plastics.

Request for a quote

IGUS® GMBH

Germany

-For medium duty use -Minor oil influence -More suitable for indoor applications, but also for outdoor use at temperatures > 5 °C -Unsupported travel distances and up to 20 m for gliding applications -Bus connection cable for machining units/machine tools, handling, indoor cranes

Request for a quote

FERPLAST SNC

Italy

MINI TWIST 140-160 CABLE - SEALING MACHINES WITH TWIST BAND Twisting manual machine, designed and built to tie different kinds of product, with a twistband wire. It is mode in varnished steel assuring a long life. The MINI TWIST is user-friendly and astonishes for its simplicity. It makes possible a grow of productivity of the worker himself. The machine is feeded by a reel of plastic wire, so-called "Twist band" which has a metal wire inside.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Two accumulation places für high speed Low maintenance Low wear Very quiet operation Also without accumulation areas possible Upstream and downstream interlocks Settings by intuitive operating terminal In conveying direction left or either right Machine movable Power cable, length 3m OPTIONAL: One pop-out roller on entry side PLC control Table height steplessly adjustable Many specific options available, easily configurable Fully electrical system, no pneumatic connection required

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 451

Request for a quote

KRAFFTER MACHINE TOOLS

France

Stroke X axis: 650 mm Max. Stroke speed X axis: 4000 mm/min Working feed X axis: 0 - 1800 mm/min Stroke Y axis: 450 mm Working feed Y axis: 0 - 1800 mm/min Stroke Z axis: 130 mm Min. Stroke speed Z axis: 0.5 mm/min Max. Stroke speed Z axis: 12000 mm/min Stroke frequency Z axis: max. 4 Hz Stroke W axis: 500 mm Planetary speed C axis: 5 - 250 rpm Max. Stroke speed W axis: 800 mm/min Stroke U axis (radial feed): 5.5 mm Distance between columns: 750 mm Table length: 770 mm Table width: 630 mm Clearance between grinding motor and table: 585 mm Max. load on table: 500 Kg Supply voltage: 400 V Weight: 4550 Kg EQUIPMENT INCLUDED: x1 HI-CUT pack including: -work area protection -exhaust system with electrostatic air filter -fire protection system (to be assessed by a qualified body) -automatic paper tape filtration unit x1 grinding motor x1 cable for grinding motor Machine visible under power in our premises by appointment.

Request for a quote

PEMAT S.C.

Poland

The male cable plug is used for connecting welding cables. The universal ŁW / ŁP type cable plug is used for connecting welding cables to the welding machine. It is mounted on mass and current wires. The plug together with the aggregate socket guarantees reliable electrical connection of the cable to the welding device. This type of connector is used in welding semi-automatic and MMA and TIG welding machines of most device manufacturers. Technical data: For cable: 35-50mm Diameter of the bolt: 12mm Pin length: 19mm Max. conductive current in 60% duty cycle (A): 316 Max. conductive current in 100% duty cycle (A): 285

Request for a quote

PEMAT S.C.

Poland

Universal connection socket fixed in welding machines, for connecting welding cables. The socket together with the plug guarantees reliable electrical connection of the cable to the welding machine. This type of connector is used in welding semi-automatic and MMA and TIG welding machines of most device manufacturers. Technical data: Connector type: 25 Cross section of the coupler (mm2): 16-25 Max. conductive current in 60% duty cycle (A): 190 Max. conductive current in 100% duty cycle (A): 180

Request for a quote

PEMAT S.C.

Poland

The male cable plug is used for connecting welding cables. The universal ŁW / ŁP type cable plug is used for connecting welding cables to the welding machine. It is mounted on mass and current wires. The plug together with the aggregate socket guarantees reliable electrical connection of the cable to the welding device. This type of connector is used in welding semi-automatic and MMA and TIG welding machines of most device manufacturers. Technical data: On the cable: 10-25mm Diameter of the pin: 9mm Pin length: 11mm Max. conductive current in 60% duty cycle (A): 190 Max. conductive current in 100% duty cycle (A): 180

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Trencher for Ferrum DM court loader / wheel loader suitable for many of our wheel loader models The 3rd control circuit is required for the trencher chain of the trencher Trench cutter with mount for quick coupler Ideal for quickly digging trenches for lines and cables in the ground or in the garden to mill to lay cables or pipes Machine is suitable for loose to medium-firm soil Recommended for: Wheel loader Ferrum DM416 x4 V2 Ferrum DM522 x4 Ferrum DM430 x4 DLZ Ferrum DM625 x4 Ferrum DM732 x4 Court loader: Courtyard loader FIRST 16

Request for a quote

TECHNIC MACHINES

Turkey

We provide for our customers different combinations of cable tray roll former machine line. Such as feeding system solutions from coil or sheet or different working parameters for cable tray roll forming machine. And also we produce our cable tray production line with different final cable tray design as to customer's request. With different cable tray width, thickness, height or with different cable tray punching solutions according to our customer’s final cable tray design. Cable Tray Roll Forming Line Units – Cable Tray Press Feeding Unit – Cable Tray Punching Unit – Cable Tray Roll Forming Unit – Cable Tray Cutting Unit – Cable Tray Coupling Unit Solutions for Cable Tray Making Machine Cable Trays have no standard sizes. Sizes can be between 50 – 1200 mm width and can be between 25 – 100 mm flange height. - Light Duty Cable Tray Roll Former - Medium Duty Cable Tray Roll Forming Line - Heavy Duty – Cable Tray Production Line

Request for a quote

PROJECT DRILL

Italy

N ° 1 puntel brand drilling rig, model PX3 / 1000 R tracked 6-cylinder 130 hp engine Stroke for rods of length 3000 mm Max pull 11 tons Rotation head with max torque 1350 kgm; 2 speeds Double vice with max passage 310 mm Winch Foam pump Winch Control panel on the side of the machine Remote cable track controls Overhauled and repainted Ideal for water wells Viewable at our office Price upon request

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This machine is not only able to crimp the biggest hoses ever for a UNIFLEX machine, it is also the most compact machine for mobile work in UNIFLEX history. The HMC 12-2000 is the most solidly built C-crimper of the 2000 ton category due to its integrated power booster for high crimping forces. After a long period of research and development in the field of FEM, this machine outshines all others of its category. UNIFLEX defines new crimping techniques and focuses on not only the highest quality and user friendliness but also advanced materials. The strongest C-Crimper for hoses worldwide •C-form crimper with 2000t effective pressforce with UNIFLEX greaseless technology •C-form crimping tool, open on the side, with an 355mm opening - no limit for flanges •Max. crimping range 380mm •For up to 3“ hydraulic / offshore / tubular & 12“ industry hoses •Robust construction for heavy duty •Ideal for special application with its high crimping force

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Cable trunking for footfall loading in machining centres PFLITSCH Automobile-Trunking complies with the works standard for many automotive manufacturers and serves as walkable floor trunking in many automated manufacturing lines and robotic production plants, allowing loads of up to 1,200 N and using antislip channelled sheet covering (slip-resistance rating R10). With seven cross sections from 100 mm to 600 mm wide, standard base perforations and universal separating walls, this robust trunking can be placed and combined with other PFLITSCH trunking systems to customer requirements. Your advantages: Walkable floor trunking with high footfall load High strength, wide support spacing Channelled sheet for antislip safety Can be combined with other trunking systems

Request for a quote

U.I. LAPP GMBH

Germany

This is the brand of choice if you want fast, safe and forward-thinking solutions for tranferring data. The range includes data cables for all electronic applications, from tiny cables in coffee machines to those transferring huge amounts of data in supercomputers. Properties: — Robust, durable and reliable. — Suitable for a wide range of uses, including under chemical and mechanical stress, in humid conditions and in various temperatures. — Suitable for fixed connection or energy supply chains. — Also halogen-free and available with international licences.

Request for a quote

JACOB GMBH

Germany

The Cable Entry Plate KADP is used to insert and seal cables in enclosures, machines and control cabinets. It provides a high flexibility for varios applications. KADP is perfect in tight spaces, as several cables can be inserted into the plate. Due to the ideal placement of the close-fitting insertion points, a high packing density with a protection grade of IP66 is achieved. The installation of the KADP into the enclosure is time-saving, by simply snapping the plate in with a single click. The cables are simply plugged in and the job is done. The "pushout" membrane re-seales almost by itself after removing the cable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RUSE SPORT

Bulgaria

We produce a huge range of fitness equipment, different types of benches: declined bench, abdominal bench, curved bench, atlas combined bench, adjustable bench, bench for crunches and upholstered for wall bar, inclined bench with adjustable weight, hypertension bench, horizontal bench, fixed flat bench, dip bar abdominal, dip bench bar abdominal, leg press, olympus combined machine, scott bench, short abdominal bench, upper bench, vertical bench, also cross trainers, tread mills, vibro trainers rowing machines, steppers, bars, dumbbells, cable machines. etc.

Request for a quote

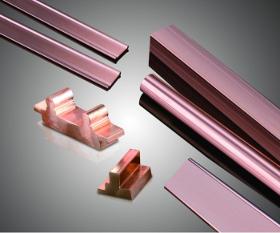

JINTIAN COPPER

Germany

Main products: TMY copper, T2 / TU2 copper rods, profiled bars, electrical round copper billets Product characteristics: High copper content, low oxygen content, compact structure, uniformity, low electrical resistivity, high electrical conductivity, precise size, excellent mechanical properties; can be customized according to demand Applications: High and low voltage electrical appliances, power electronics, power transmission and transformation, automotive industry, molds, communication technology, cables, machining, metallurgical chemicals, construction industry Production capacity: 100,000 tons Honorary titles: Zhejiang Famous Brand Product

Request for a quote

HEINZE & STRENG GMBH

Germany

Due to a lot of different manufacturing method we have the following types: Press-fit slipring collectors: max. length of 420 mm Injection-moulded slipring collectors: max. OD: 100 mm Shrink-fit moulded slipring collectors: max. dimension up to 1 m Ø Application fields: Cable Stranding Machines Gears Pumps Fans Tinning Lines Annealing Machines

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Allows the counter to be reset to zero manually at the push of a button or program controlled during marking. Option PN comprises of a compact compressed-air cylinder in the marking wheel and a RESET key on the machine’s control panel. Programmable, automatic reset function requires Option W. W - PROGRAMMABLE ELECTRONIC CONTROL MODULE FOR PN PNEUMATIC RESET SYSTEM OR OTHER PNEUMATICALLY OPERATED FUNCTIONS Causes, for instance, the counter to be reset to zero or the marking wheel to be lifted every time a preset length of cable has passed through the machine. An additional, programmable contact closure allows an external process (e.g., cutting the cable at a preset length after the counter has returned to zero) to be triggered. 2W - EXTERNAL DEVICE PRE-SELECTION Option 2W features a second pre-selection counter to be used for controlling an external device, e.g. for triggering a cutting device when achieving a pre-defined length of the marking good. The pre-defined length corresponds

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

B - STROBOSCOPE Automatically synchronized flashing stroboscope for monitoring the quality of printed marks. High quality finish with tight and resistant to solvent metal casing. VST - VIDEO SYSTEM FOR MONITORING THE PRINT QUALITY Medek & Schörner also offers a video system for monitoring the print quality of fast-running cable printing machines, e.g. allowing real-time inspection for bad quality and/or missing prints. FM-P - REPLACEABLE INK SUPPLY MODULE With ink tank, pump, cooler, filters, and ink flow fine adjustment and selector valves. Allows the printing ink to be changed in about 2 minutes. Ink can be stored in the ink tank for several weeks with no degradation of ink properties.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Produce your air cushions automatically to avoid unnecessary waiting times. Once the stock level is reached, your AirWave1 or AirWave2 automatically stops the production using the level sensor. The machine automatically starts again as soon as cushions are removed from the container. The level sensor with infrared light barrier has a sensor range up to 400 mm. Fits the AirWave1 and AirWave2 air cushion machine. Cable length: 1.35 meters

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

The VST video stroboscope has been designed to continuously monitor the print quality of fast-running cable printing machines. The system also offers the convenience of being able to view the entire print area at various magnifications on a monitor screen. The integrated software allows various evaluations of the displayed print area; e.g. alarm in case of bad quality and / or missing prints. Print monitoring at speeds up to 2500 m/min and above Real-time inspection for bad quality and /or missing prints The device is e.g. synchronized with the gravure printer's stroboscopic signal output (12 pulses per printwheel revolution). A special high-speed camera periodically takes a sequence of 12 consecutive partial print photographs depicting the total print impression printed by the printwheel circumference and outputs them via a 1 Gb/sec Ethernet interface to any computer (not included with the basic VST Video Stroboscope).

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

Indent marking or embossing of cables up to 30 mm in diameter immediately after the extruder head. Indent marking or embossing Single or double-sided marking Line speeds up to 1000 m/min STANDARD CONFIGURATION Frame with support column and crank-operated height adjustment mechanism. Marking head with cooling trough. Marking wheels and guide rollers available separately.Marking machine for insulated cables. Indent marking or embossing. Single or double-sided marking. Marking wheels mounted on water-cooled shafts to prevent insulation from sticking to marking wheels and ensure perfect marking at extrusion line speeds of up to approx. 1000 m/ minute. Height of each marking wheel adjustable separately. SPECIFICATIONS Max. printing speed: 1000 m/min Product diameter: 1.5 mm to 30 mm Marking wheels: 86 mm in diameter ACCESSORIES Marking wheels Pressure rolls

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 5000 range includes the flagship models for precise processing of thick cables up to 240 mm² section and 35 mm diameter. Even the basic specification models, with their high torque and powerful three-stage step motors offer the highest level of cutting and haul-off power. All models are equipped with as standard with the Metzner double-knife system that enables very varied and multi-stage processes to be performed. Moreover, with convincing operator-friendliness and long service life. Metzner AM 5000 models are also suited to processing thinner braided cables from 1.5 mm² The stripping full haul-off 1side/2nd side amount to 270-450 mm and 90-270 mm, for partial haul-off 450 mm and 270 mm. For interuption-free automatic production, a number of sensors monitor the material feeding If a material blockage occurs, the production stops automatically and the operator is informed about the cause of the fault.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quoteResults for

Cabling machines - Import exportNumber of results

59 ProductsCountries

Company type

Category

- Mechanical engineering - custom work (9)

- Copper wires and cables (6)

- Cutting, plastics - machinery (5)

- Professional fitness equipment (4)

- Cables, high-voltage (2)

- Gas, compressed (2)

- Metallurgy and iron and steel industry - machinery and installations (2)

- Optical fibres (2)

- Silicones (2)

- Apparatus for gymnasiums (1)

- Cable ducts (1)

- Cables - accessories (1)

- Coil winders (1)

- Construction machinery (1)

- Copper and copper alloys (1)

- Drilling machinery (1)

- ELECTRIC EQUIPMENT (1)

- Electric and electronic components - machines for manufacturing (1)

- Electric cables (1)

- Gases, compressed and liquefied (1)