- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bulk bag filling systems

Results for

Bulk bag filling systems - Import export

SPF SWEDA LTD

Ukraine

The Big-Bag packing machine SWEDA DWS-301-1000-1-P is intended for batching bulk materials into super sacks (“Big-Bag”). The Big-Bag filling machine can be used for batching cereals, sugar, compound feed, mineral fertilizers, granules and other bulk materials. The FIBC fiiling machine SWEDA DWS-301-1000-1-P is structurally different from the FIBC packing machine SWEDA DWS-301-1000-1 by the presence of additional units: a weighing belt conveyor (instead of a weighing platform), a storage belt conveyor and an overhead feed hopper. Features: -Increased capacity (up to 35 bags per hour); -Stainless steel tract (optional); -Fan for blowing the bag eliminates spillage of the product; -Automatic ejection of the straps and the removal of the bag from the batching area; -Communication with the automated control system of the enterprise and the owner’s office; -There are no special requirements for operating conditions and staff; -Prompt mounting, adjusting and put into operation.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec Big Bag filling stations are suitable as standard for filling big bags with a capacity of up to 2 tons. Various options are available to meet the required task. Also a calibratable weighing of the filled Big-Bas. The Big-Bag filling station offers a variety of options: - height-adjustable suspension frame - Tightening of the big bag by means of linear drive - Double big bag filling - vibration table for compacting the products, etc., ... to name just a few.

Request for a quote

GERI TRADING SRL

Romania

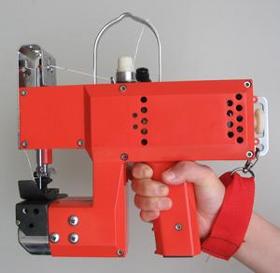

Portable bag closer sewing machine Model : NP-7D (two needles two threads) Brand Keestar (CN) Sewing type : dbl. stitch chain Sewing step : 6,5 mm Sewing speed : 1.250 spm Tension 220V/50Hz Weight 5,8 Kg Cutting the chain : automatic

Request for a quote

GERI TRADING SRL

Romania

Characteristics : The packed material is of the powder type (flour, malt, etc.). Weighing range: 10 - 50 Kg / bag. Accuracy: ą 0.1% -0.5%. Weighing / packing speed: 240 - 540 bags / hour. Supply voltage: 380V (50Hz).. Optionally the line can be equipped with the following devices: - Bundle printing of the date of validity, packing, lot number, etc. - vertical loader for feeding the silo in which the weighing and filling material of the bags is stored Depending on the specifics of the user, closing of the bags can be done by thermal bonding instead of sewing (specific for packing in transparent polyethylene bags).

Request for a quote

VRASTICANKA

North Macedonia

100% polyester thread , waxed , for closing bags . Packing on 150,200,250 gr , 1kg ,2kg .... High quality Polyester Twine Ne 12/3 , 12/4 , 12/5 , 12/6

Do you sell or make similar products?

Sign up to europages and have your products listed

GERI TRADING SRL

Romania

The band transport conveyor GKS has a large capacity for bags supply at a high speed bag closer sewing head. This conveyor is part of an automatic line suitable for agriculture sectors where bags packaging and storage are also requested. Whenever such conveyor is working, bring the effortless of operators, while productivity level become higher and packaging cost are decreased. Characteristics : Band length :2,0 - 4,0 m. Band wide :400 mm. Transport speed :6,7 - 22 m/min. Transport capacity :20 - 100 tone/h. Tension :380 V. Motor power :0,55 Kw. Price : from 650 Euroas to the band's length requested.

Request for a quote

GERI TRADING SRL

Romania

Portable bag closer sewing machine Model : GK - 1800 Brand Keestar (CN) Sewing type :chain stitch Sewing step : 6 - 8mm Sewing speed : 1600 spm Tension 220V Weight 3,5Kg Cutting the chain : automatic

Request for a quote

GERI TRADING SRL

Romania

Characteristics : The packaged material is granular (grain, rice, salt, sand, etc.). Weighing range: 1 - 25 Kg / bag. Two weighing tanks (double the weighing speed). Tolerance: 0.2%. Weighing / packing speed: 360 - 900 bags / hour. Supply voltage: 380V (50Hz). Price at request. Benefits : - two weighing tanks that will increase packing capacity and intake Optionally the line can be equipped with the following devices: - conveyor belt with variable length between 2m and 4m. - Bundle printing of the date of validity, packing, lot number, etc. - vertical loader for feeding the silo in which the weighing and filling material of the bags is stored Depending on the specifics of the user, closing of the bags can be done by thermal bonding instead of sewing (specific for packing in transparent polyethylene bags)

Request for a quote

B+B ANLAGENBAU GMBH

Germany

An automatic big bag filling station supplied by B+B completes the washing line of the plastic recycling process. Inquire for more information on options.

Request for a quote

SPF SWEDA LTD

Ukraine

Open-mouth bag filling machine DWS-301-50-1 is intended for packing of free-flowing materials in open-mouth bags. By means of the bag packing machine SWEDA DWS-301-50-1 it is possible to pack up in sewing (open) bags (paper, polypropylene, jute) free-flowing products, including food. Long-term operating experience of bag filling machine SWEDA DWS-301 for packing of sugar, grains, seeds, cereals, granulated powders, pellets and other free-flowing substances and materials has confirmed it’s high accuracy and reliability. Features: - High capacity (up to 400 bags/hour) and batching accuracy (class 0.2); - Stainless steel tract with dust cover; - Work 24/7; - Possibility of communication with the automated control system of the enterprise and the owner’s office; - Easy to operate, without difficult settings and menus; - There are no special requirements for operating conditions and staff; - Operational mounting, adjustment and put into operation.

Request for a quoteResults for

Bulk bag filling systems - Import exportNumber of results

11 ProductsCountries