- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brazing and welding

Results for

Brazing and welding - Import export

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Turn Table, precisely provide to welding by turning clockwise or counterclockwise of parts connected to it horizontally. It also enable movement in the rotation axis. . The work table is operated with a T-slot turntable to ensure that the workpieces are fully fixed to the work table. It is designed with the aim of increasing efficiency, eliminating the need for welding in difficult positions and considering ergonomics of employees.

Request for a quote

CLIMADI REFRIGERANT SRL

Romania

5 Tips About Welding Mapp PRO Gas You Can Use Today Posted February 7, 2011 My uncle used Mapp fuel For several years also. I’ve use both acetylene or propane For some time as Mapp wasn’t that prevalent listed here as it absolutely was where by he lived. BLUEFIRE Handy Cyclone Propane Brazing is greatly utilised and can be done on steel pieces that can not be welded. As opposed to welding, brazing is more rapidly, easier, and safer than other welding procedures. This oxygen is then ship to your brazing web page in higher-tension vessels. Within a Dewar-variety vessel, liquid oxygen is separate from your air utilizing a zeolite sieve. The zeolite adsorbs nitrogen and lets oxygen move, which leads to a purity of 93%. The upper the purity with the oxygen, the higher the process of reducing.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Argon-arc welding Electric arc welding Gas metal arc welding Arc welding"

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

Welded construction parts are manufactured all according to ISO Standards of certifed Suppliers.

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

With our extensive supplier portal, we can cover all your needs in the field of cold and hot forged castings. Trust us in choosing the right supplier for your needs

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

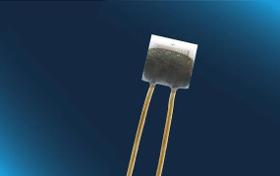

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

DOGRAR METAL

Turkey

Our machines with 1500x3000 mm and 2000*4000 mm capacities can process 0.5 - 20 mm stainless steel, S235 JR and aluminium and 0,5 - 8 mm copper, brass and titanium at high speed. No matter whether manufacturing low quantities or mass production, we are guaranteeing ISO 9001:2015 quality level and the best raw material optimization, thanks to powerfull TRUMPF machinery since 2004. The determining factor in quality and efficiency is the machine as a complete system of laser power and functions. That's exactly why you can’t produce a good part without good technology, and we always adopt the principle of production with the best technology. At the same time, with the automatic loading units we have, we can place the raw material in the machine without damaging the surface quality, and we can save a lot of time in this process compared to the traditional loading method.

Request for a quote

DOGRAR METAL

Turkey

Tube and section laser cutting provides many advantages such as new design opportunities, declining manufacturing steps or easier welding methods from machinery to furniture sector. Thanks to Trumpf TruTube 3000 Fiber that we have included in our machiner in 2021. we can process tubes and sections up to 170 mm diameter or side dimensions. Laser cutting of tubes and sections, used in a wide range from the machinery industry to the furniture industry, offers you new pipe and profile construction possibilities that cannot be realized with traditional methods in pipe and profile construction. All kinds of contours and shapes that cannot be made with traditional methods are achieved with laser with low tolerances and at the same time saving time. In addition to the ease of processing, you can also simplify further manufacturing steps with the created contours. For example, with the positioning aids obtained by creating male and female contours on opposite sides

Request for a quote

DOGRAR METAL

Turkey

Fanuc Arc welding robot with 2 meters reaching capacity can weld 5 mm -20 mm parts with multi dimensional and efficient methods. Thin design makes the robot ideal for usage in different sectors from automotive to furniture industry. Unlike traditional welding methods, you can achieve the quality from first to last part. In addition to TIG welding, We are also working with other welding methods such as stainless steel welding (MIG/MAG) and spot welding depending on our client's needs and material preferences.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOGRAR METAL

Turkey

Our machine selection may bend 240 and 300 IPE and NPI. and pipes from 21 to 76. Moreover, we can process from 15x15 rolling mills to 60x60 rolling mills also, from 20^5 sheet bar to 80x20 sheet bar.

Request for a quote

DOGRAR METAL

Turkey

Our machines with 2500x6000 mm and 2500x12000 mm capacities can cut 2-30 mm galvanized steel and ST 37 and 2-15 mm stainless steel. Also, they may process as inclined method for the sheets thicker than 10 mm. With our plasma cutting machines that can cut up to 12 meters in length, high thickness materials can be processed with high precision. With this production method, which has high durability and low energy consumption, production can be made at low cost. With the oxygen cutting method, we can shape materials up to 200.00 mm in thickness with additional fprhnologies such as micro-joint at a speed of 15 mitpr per minute.

Request for a quote

FÖHRENBACH GMBH

Germany

With high demands on accuracy and dynamics, the base frame in welded construction or hard stone is also a possible and reasonable part of the scope of supply. Here, all axes are specified, assembled, aligned, measured, tested and recorded - according to desired specifications. By means of hard stone, the required accuracies can be achieved. Hard stone offers all the characteristics required - ranging from a small coefficient of expansion, high abrasion resistance, optimum vibration damping, absence of unwanted residual stresses up to the necessary accuracies regarding flatness, parallelisms and angularity.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures various steel frames for various structures and machinery. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse We have around 150 different versions of Socket Weld Outlets (ANSI B 16.11 / MSS SP 97) in our extensive warehouse in Kamen. We can deliver to you at short notice at any time. We only deliver goods of European origin. Standards and special requests We supply socket weld outlets in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply special materials on request. Furthermore, socket weld outlets differentiate between reduced and full branches. Express service We can deliver socket weld outlets in stock to the customer within Germany the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service. Technical specifications More details, technical data and dimensions can be found in our data sheet “Socket weld outlets” in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Swept outlet similar to ANSI B 16.19 / ANSI B 36.10 Swept outlets in pipeline construction A swept outlet is used in pipeline construction just like a welding outlet, a socket welded outlet or a threaded outlet for a 90 ° branch. A swept outlet is an alternative to the T-piece / red. In comparison to the T-piece / Red.Tee, the installation effort for a swept outlet is lower because only one hole has to be drilled into a pipe. The swept outlet can then be welded into this hole. A swept outlet differs from a welding outlet in the type of welding. While a welding outlet is only placed on the run pipe and then welded, a swept outlet is welded directly into the run pipe. Ideal stress distribution Swept outlets were developed in order to achieve the best possible stress distribution for internal pressure and pipe forces. Due to the favorable voltage level, swept outlets are often used in highly stressed pipes in the oil and gas industry.

Request for a quote

ANTHERMO GMBH

Germany

Numerous designs available at short notice Support-free assembly Nipple outlets (MSS SP 97) have been specially developed for support-free assembly. Nipple outlets are available with different ends. Smooth or beveled ends are used for welded connections, while the ends have an external thread for screw connections. We can deliver nipple outlets with NPT thread according to ASME B1.20.1 from our warehouse. We can deliver nipple outlets with BSP / T threads according to ISO 7-1 and BSP / P threads according to DIN ISO 228 with short delivery times. Standards and special requests We deliver nipple outlets in different wall thicknesses (STD, XS, S 160 & XXS and special wall thicknesses) as well as in all common materials. If required, we can also supply special materials. Technical specifications You can find more details, technical data and dimensions in our data sheet "Nipple outlet" in the download area.

Request for a quote

ANTHERMO GMBH

Germany

Numerous designs available at short notice Branch connections on straight pipe sections Lateral outlets are used for 45 ° branches on straight pipe sections. Other departure angles are possible on request. Standards and special requests We deliver lateral outlets in two pressure levels (3,000 lbs and 6,000 lbs) and in all common materials. If required, we can also supply special materials. Technical specifications You can find more details, technical data and dimensions in our data sheet “Lateral outlets” in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Elbow outlets for 90 ° bends 1.5 D Up to 2 “elbow outlets fit on elbows of all diameters mentioned in our data sheet (see download area). Larger branches are manufactured precisely for the respective arch diameter. Standards and special requests We deliver elbow outlets in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. If required, we can also supply special materials. Technical specifications More details, technical data and dimensions can be found in our data sheet "elbow outlets" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quoteResults for

Brazing and welding - Import exportNumber of results

200 ProductsCountries

- Germany (74)

- Turkey (34)

- United States (20)

- Poland (16)

- Switzerland (11)

- Russia (8)

- China (5)

- Belgium (4)

- Italy (4)

- Slovakia (4)

- Austria (2)

- Portugal (2)

- Romania (2)

- Serbia (2)

- Ukraine (2)

- United Kingdom (2)

- Belarus (1)

- Czech Rep. (1)

- Denmark (1)

- France (1)

- Hungary (1)

- Luxembourg (1)

- Spain (1)

- Taiwan R.O.C. (1)

Company type

Category

- Steels and metals - welding and brazing (78)

- Welding, soldering and brazing - equipment and supplies (76)

- Steel & Metals (21)

- Autogenous welding machines (7)

- Welding work - steels and metal (7)

- Brazing - steels and metals (6)

- Sensors (6)

- Brazing - equipment and supplies (3)

- Laser - cutting and welding machines (3)

- Steel (2)

- Welding, electric - equipment and supplies (2)

- Aluminium sheets and bands (1)

- Bending - steels and metals (1)

- Chemical metal treatment (1)

- Epoxy resin (1)

- Gas and oil pipelines - installations (1)

- Grinding - machine tools (1)

- Induction heating systems (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Refrigerants (1)