- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- boron carbide and boron nitride

Results for

Boron carbide and boron nitride - Import export

TRADIUM GMBH

Germany

At TRADIUM, boron metal is available in the following forms for industrial use: - Boron powder - Nano boron - Borides: aluminium boride, magnesium boride, titanium boride, zirconium boride - Boron carbide - Boron nitride Your point of contact for boron is: Thomas Grob Phone: +49 (0)69 50 50 250 - 233 We are looking forward to hearing from you!

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Material of Boron Nitride Ceramics: Pyrolytic Boron Nitride: 99.99% Boron Nitride* 99 Boron Nitride: Boron Nitride + Boric Oxide (B2O3) CABN: Boron Nitride + Calcium Borate ALBN: Boron Nitride + Al2BO3 ZRBN: Boron Nitride + Zirconium Oxide + Boric Oxide (B2O3) ZABN: Boron Nitride + Zirconium Oxide + Aluminum Nitride + Al2BO3 SCBN: Boron Nitride + Silicon Carbon + Al2BO3 Processing of Boron Nitride Ceramics: 1.Hot Pressed Sintering 2.Chemical Vapor Deposition

Request for a quote

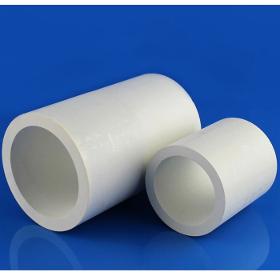

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron Nitride Specifications: >Outside Diameter: 6.40 mm >Inside Diameter: 1.70 mm >Wall Thickness: 2.35 mm >Length: 100 mm >Condition: Hot Pressed >Custom size is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials, this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride: 1.High thermal conductivity 2.Low thermal expansion 3.Good thermal shock resistance 4.High electrical resistance 5.Low dielectric constant and loss tangent 6.Microwave transparency 7.Non toxic 8.Easily machined — non abrasive and lubricious 9.Chemically inert 10.Not wet by most molten metals

Request for a quote

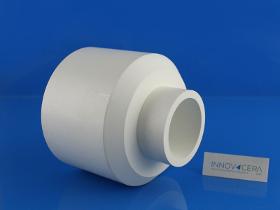

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA can improve material proportion and complete solution according to industry demand to achieve the best effect of customer use. Boron Nitride Ceramic Rod Characteristics: High thermal conductivity, pressed into various forms, used as high temperature, high pressure, insulation, heat dissipation components, such as aircraft, rocket engine nozzles. 2. Excellent thermal shock resistance and erosion resistance. It is used in Amorphous Ribbon Making and amorphous nozzles, three-dimensional printing metal powder diversion tubes, nozzles, etc. 3. High strength non-sticking, applied to various hot-pressing dies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Name: high temperature resistant BN gold melting crucibles Borons Ceramic Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss

Request for a quote

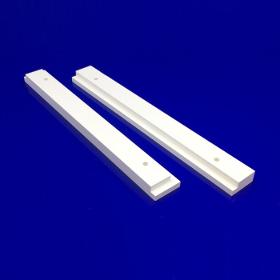

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

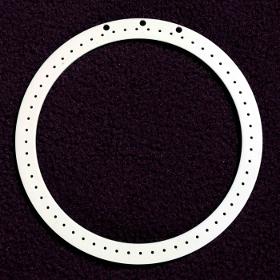

The boron nitride setter plate is made of high purity 99.7% boron nitride ceramics, has a high operating temperature in an inert gas (2100℃) and vacuum (1900℃) environment. It has excellent thermal shock resistance which can be used for applications having sudden temperature changes. It will not react or wet with a wide range of molten metals and glass. It is also a good electrical insulator. Boron nitride ceramic setter plate for sintering AlN Si3n4 Substrates. The maximum size to produce is 480mm x 480mm, plain holes, thread holes, grooves or shoulders could be machined on the plate. In this field, we can offer precision machined components. Features of 99.7% Boron Nitride: * High thermal conductivity * Low thermal expansion * Good thermal shock resistance * High electrical resistance * Low dielectric constant and loss tangent * Microwave transparency * Non-toxic * Easily machined — non-abrasive and lubricious * Chemically inert * Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron Nitride is very often machined to isolation components which works in PVD euipments. They are be installed as replacement parts in PVD Magnetron sputtering systems. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina PVD/CVD vacuum coating equipment insulation accessories > Used for ion coating machine, sputtering coating Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina > Used for polysilicon ingot furnace, graphitization heat treatment furnace, vacuum sintering furnace, atmosphere furnace ect. Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

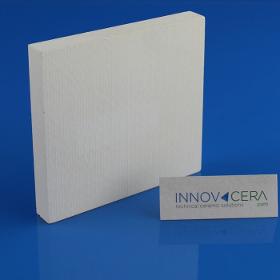

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Hot Press Boron Nitride Sheet Thickness 2 mm, 3 Square in stock (25 x 25 mm, 50 x 50 mm, 200 mm x 240 mm), custom size is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride: 1.High thermal conductivity 2.Low thermal expansion 3.Good thermal shock resistance 4.High electrical resistance 5.Low dielectric constant and loss tangent 6.Microwave transparency 7.Non toxic 8.Easily machined — non abrasive and lubricious 9.Chemically inert 10.Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Due to the nature of the CVD process, PBN parts generally are requested a wall thickness not more than 3mm. PBN is also a good choice for the extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process gives this pyrolytic boron nitride an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. Pyrolytic Boron Nitride Applications: Crystal growth (VGF, LEC Crucible) Molecular Beam Epitaxy(MBE) Crucible MOCVD Heater PBN Infrared Window Traveling Wave Tube (TWT) (PBN Support Rod) PBN Coating Graphite High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss PBN Plate Applications: For vacuum, high temperature, MBE equipment and other fields of insulation gasket, gasket, support, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. Material Properties: * High thermal conductivity * Excellent thermal shock resistance * Low thermal expansion * Exceptional heat resistance * Good Chemical Inertness * High electrical resistance * Low dielectric constant and loss tangent * High volume resistivity * Excellent machinability Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quoteResults for

Boron carbide and boron nitride - Import exportNumber of results

16 ProductsCountries

Company type