- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- block machine

Results for

Block machine - Import export

ELKON GMBH

Germany

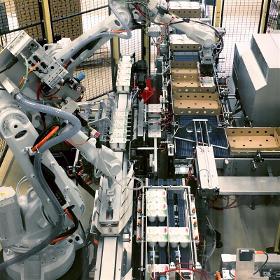

ELKOBLOCK-36S single pallet concrete block making machine which is specially designed by experts in their field to produce different types of blocks such as interlocks, curb stones, hollow blocks, solid blocks, etc. has the capacity to produce concrete paving stone approximately 1.400 square meters in an 8 hours shift. Optimum operation is provided for production, curing, additional processing and packaking according to preferred method of single pallet concrete paving and block making machine which can be used with high performance finger car robot or cage system layout.

Request for a quote

ELKON GMBH

Germany

With more than 44 years of experience, technological production and innovative approach in concrete machinery, ELKON has designed premium block making machine aiming at sustainable high quality and optimum performance in block production. ELKOBLOCK-36M which is specially designed by experts in their field to produce different types of blocks such as interlocks, curb stones, solid blocks, etc. has the capacity to produce concrete paving stone over 1.000 square meters in an 8 hours shift. Heavy duty design, robust machine structure and certified high grade steels used in production ensures highest durability and longest life time. Four columns system with chrome-plated guides for tamper head improves stability of machine and guarantees parallel movement of tamper head.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO CO2 Gas Revert Recovery Systems are engineered to efficiently recover the revert CO2 gas from ASCO Dry Ice Pellet and Block Machines which normally direct the revert (flash) gas to the atmosphere. When dry ice is produced the conversion rate from liquid CO2 to dry ice is approx. 4045 %. This means 5560 % is lost to the atmosphere. This conversation rate is a physical fact and therefore, unfortunately, not to change. With a CO2 Revert Recovery System, however, most of the CO2 can be recovered which leads to a final conversion rate of approx. 9095 %. This way, the dry ice production costs are reduced up to 50 %.

Request for a quote

SCHNELL SPA

Italy

Machine to cut (EPS) polystyrene blocks in sheets, useful for the production of precast sandwich panels. The machine cuts the blocks horizontally and vertically and obtains polystyrene sheets of different thicknesses and shapes.

Request for a quote

TITAN MACHINERY

United Kingdom

A sand-lime brick making machine is a specialized piece of equipment designed for the production of bricks made from a mixture of sand, lime, and other additives. These bricks are also known as silica sand bricks or sand-lime bricks and are recognized for their excellent quality and durability. Sand-lime brick making machines are widely used in the construction industry to produce bricks that are known for their strength and resistance to environmental factors. These bricks find applications in various construction projects, including residential, commercial, and industrial buildings. They are valued for their durability and suitability for both load-bearing and non-load-bearing walls.

Request for a quote

TITAN MACHINERY

United Kingdom

A brick and block making machine is a versatile piece of equipment capable of producing high-quality bricks, blocks, and tiles. These machines are essential in the construction industry, providing the means to create durable and reliable building materials. Whether it's for residential, commercial, or industrial projects, these machines play a crucial role in meeting the demand for robust construction materials. They offer precision in molding, ensuring uniformity in size and shape, which is vital for structural integrity. With advancements in technology, modern brick and block making machines are designed for efficiency, allowing for faster production without compromising on quality. They can handle various raw materials, including concrete, clay, and fly ash, making them adaptable to different construction needs. In addition to standard bricks and blocks, these machines can produce interlocking blocks, paving tiles, and more, expanding their utility in the construction world.

Request for a quote

SCANDINAVIAN & UK MACHINES

Sweden

Capacity – 1 concrete ring in 5-7 minutes. Technical description: Block height floor production: 500-1000 Useful height of machine: 1000 mm Production area: 1500 x 1500 mm Installed electrical power 25 kW Number of high-frequency vibrators: 6 pieces Machine weight with a mold and without a face mix device - 8750 kg Fully automatic model. "Scandinavian & UK Machines" provides full service in mobile and stationary batching plants; block, paving, curbs and wall panels producing equipment; cold asphalt plants; cement unloading equipment supply - consultations, projection, installation, specialists training, service, spare parts delivery.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

Line of Machine equipment for the production of wall blocks controlled by PLC automation. Machine with a powerful hydraulic configuration, is able to produce blocks into 140-150 pallets per hour. This kind of Machine produces 12 pieces of 20-th blocks in 1 cycle. The batching plant that provide the Machine by mortar is controlled semi/full automatically that’s up to client. The PARS12 blocks making machine has also the operative and quick mold changing system. It makes the machine ideal for producing different kinds of blocks. General Options Easy to install Easy commissioning and repair Pneumatic and hydraulic cylinders Efficient operation with high productivity Low investment and operating costs Easy to clean Opportunity for long-term work System simplicity Reliable emergency system

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

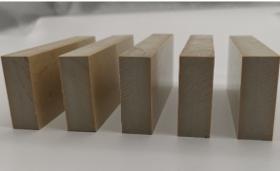

This machine has been designed in order to produce high quality of interlocks, blocks,curbstones and other concrete products as requested by the customer. One press can produce 42pcs of interlocks or 18 pcs from blocks 20x40x20cm block and curbstones. The machine can be used with a stacking system or without stacking system. The press time is 20-24 seconds. It has two working system, it can work either full automatic or semi automatic depending on user preference. Movements on the system will be controlled by a PLC. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood. There are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce interlocks,blocks,curbstones and other concrete products as requested by the customer. In one press it can produce 36 pcs of interlocks, or 12 pcs of 20x40x20cm block The press time is 18-22 seconds. It has two working system, it can work either on full automatic or semi automatic depending on user preference. The machine can be used with a stacking system or without a stacking system. Movements on the system will be controlled by plc. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood there are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed then transported up to the mixer.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

UMMANMAK

Turkey

The main field of activity of our company is the production of machines that produce products such as paving stones, borders, briquettes, tile stones in various shapes and sizes. These machines are full-fledged concrete block production facilities together with aggregate bins and weighing units, concrete mixers, conveyor belts. Umman Machine uses the high quality products of the leading companies in their own sectors in the manufacture of all machinery and auxiliary equipment. Combining its experience and knowledge of more than half a century with quality raw materials and workmanship, Umman Machine produces our machines and products that will work for many years without any problems and with full efficiency, under the assurance of CE .ISO 9001 2008.TSE, OHSAS. Concrete parquet production

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the aluminium blocks with Anodized Gold,Machining into a cavity.Mainly used in architectural decoration industry.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

SYNERLINK

France

EL STEP combines the operations of cardboard overpacking and packaging in a single machine block. This equipment can handle different formats of cups as well as bottles. This solution has a number of advantages. It combines compactness, flexibility, performance and ergonomics. The equipment’s four stations (destacking, transfer, folding-gluing and packaging) take up very little space (3x6 m). The machine’s modular architecture and the choice of sequential multi-row operation allows adaptation to the machine’s rates — from 30 to 200 overpackings per minute. Format change takes very little time and can be done by an operator at human height. EL STEP is totally designed to be interfaced with any SYNERLINK machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PEEKCHINA CO., LTD.

China

PEEK material performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK ARKPEEK-GF30: 30% glass fiber + 70% PEEK ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC milling. The surface treatment is zinc coating.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The material is stainless steel. The process is CNC milling. The finish is anodizing.

Request for a quote

HOVMAND A/S

Denmark

When it comes to handling large and heavy paper, cardboard and plastic reels, COMPACT is the right choice. The smallest battery-operated lifter on the market features a combined boom with wheel for easy lifting of rolls up to 100 kg and a rotating V-block for special reels with axle up to 60 kg. A cost-effective alternative for those who like to keep things simple. This ensures your reels are transported safely from A to B – and all the way to the packaging machine (perhaps better: further processing machine?). Our COMPACT lifter is a simple, self-explanatory lifting solution, specially developed for the printing and packaging industry. And it’s so simple: pick up the reel on the boom or the V-block, run to the machine, apply the brakes and then comfortably push the roll from the boom or V-block into the machine.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Reformer R70i has been developed for producing dense dry ice blocks in various sizes by compressing dry ice pellets. Be it in combination with an existing or with a new dry ice pelletizer, the ASCO Dry Ice Reformer R70i is a very convenient tool to complement the dry ice pellet business with dry ice blocks. The compact machine is driven by a powerful and unique hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC. A Siemens touch screen provides good overview and easy operation, a comprehensive monitoring, easy maintenance and optimal service planning. An integrated production control system allows to define and supervise the amount of blocks or weight to be produced.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO’s automatic Dry Ice Machine BP425i produces slices in ten different thicknesses and two different types of pellets with a diameter of 3, 6, 10 or 16 mm (1/8, 1/4, 3/8 or 5/8 in) at the push of a button. Standard slice dimensions are 210 x 125 x 20 125 mm (8.3 x 4.9 x 0.8 4.9 in). Other slice/pellet dimensions are available on request. Depending on the setting, the production capacity ranges from 190 to 400 kg/h (418 to 882 lb/h). The dies for the production of different sizes do not have to be changed manually as they are already builtin and can be controlled at the touch screen panel. The automatic dry ice block, slice and pellet machine ASCO BP425i belongs to the ASCO iSeries line.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO’s automatic Dry Ice Machine BP420i produces slices in 10 different thicknesses and 2 different types of pellets at the push of a button. The dies for the production of different sizes do not have to be changed manually as they are already built in and can be controlled at the touch screen panel. The BP420i features high density, fully automatic dry ice production for slices in ten different thicknesses. In addition, it is possible to produce pellets in two different sizes with a diameter of 3, 6, 10 or 16 mm (1/8, 1/4, 3/8 or 5/8 in). Standard slice dimensions are 210 × 125 × 20 70 mm (8.3 x 4.9 x 0.8 2.8 in). Other slice/pellet dimensions are available on request. Depending on the setting, the production capacity ranges from 240 to 400 kg/h (529 to 882 lb/h). The automatic dry ice block, slice and pellet machine ASCO BP420i belongs to the ASCO iSeries line.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Machine Block Brush

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Our large range of tool and engineering steels can easily combine toughness with conditioning, shaping and cutting. All these steels respond adequately to your needs of manufacturing hard and resistant tools and moulds. Whether you need them to withstand impact loading or to enable sharp cutting edges, they are made to ensure performance and durability. As a result of the right balance in alloys, our tool steels support high temperature without deformation. Their structure enhances their polishing properties. We can deliver quality tool steels as blocks (raw or machined) or as round bars (raw or peeled). Our extremely large range of thickness renders steels that meet your highest expectations. Applications : Plastic molding dies, die-casting die blocks, blanking and stamping dies, metal cutting tools, extrusion tools, hammers and sledges, etc.

Request for a quote

SCHNELL SPA

Italy

Machine used to reinforce the polystyrene insert (EPS) of the Reinforced Thermal Block. The machine inserts automatically the vertical wires and their connectors into the polystyrene core.

Request for a quote

KITTNER ANLAGEN - UND MASCHINENBAU

Bulgaria

The machine is designed for cleaning and degreasing of engine blocks, gearboxes, and other machine parts. The dimension of the engine block 2500x950x800 mm and load capacity max. 2500 kg. The parts are placed on a mobile table, which is positioned in front of the machine and via a mechanical actuator, the board of the table moves inside. The cleaning is carried out by three nozzle collectors – two fixed and one movable. The machine has a mud sump and oil separator. The mud sump catches gross dirt larger than 1.5 mm. The band oil separator is designed for separation of the oil from the washing solution. Machine corpus made entirely out of stainless steel, material No. 1.4301. The machine complies with the high CE-Requirements and EU- and USDA regulations.

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply EPS block molding machines, suitable for various capacities and sizes - from the smallest of 2 x 0.5 x 1 (m) to the biggest of 6 x 1.25 x 1.25 (m). We can also supply the block molding machines with the adjustable side and/or bottom. You can learn more about our products and services by visiting our web site - https://www.estechtic.net/ or you can send your inquiries to fr@estechtic.net.

Request for a quoteResults for

Block machine - Import exportNumber of results

98 ProductsCountries

Category

- Brick-making - machinery and equipment (26)

- Concrete blocks (17)

- Carbon and graphite - electrical components (10)

- Concrete mixers (10)

- Food industry - machinery and equipment (5)

- Cooling and lubrication pumps (4)

- Cutting, plastics - machinery (4)

- Epoxy resin (3)

- Aluminium and aluminium alloys (2)

- Cement-making - machinery and equipment (2)

- Concrete preparing - machinery and equipment (2)

- Gantry cranes (2)

- Insulating panels, asbestos-free (2)

- Adjustment - machine tools (1)

- Aluminium alloys (1)

- Assemblies, hydraulic (1)

- Ceramics, industrial (1)

- Concrete forms (1)

- Concrete, ready-mixed (1)

- Connectors, electronic (1)