- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bending presses

Results for

Bending presses - Import export

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

MAHERAS LTD.

Bulgaria

We have hydraulic press brake for flatness bending.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Abkant (Press Brake or Bending Press) machines are a type of bending press. They are used in operations such as metal bending and metal curling. Nowadays, many computer-controlled Abkant machines are available. These machines have accelerated the production in terms of both form utility and time saving. With Abkant curling cylindrical, conical, elliptical and oval shapes can be provided. The length, thickness and type of the material (stainless, aluminum, steel sheet, etc.) to be curled are important in the choice of Akbant machine. Akbant machines have individual molds and specific radiuses for various bending operations. The angle calculation of the sheet while performing bending operation using Abkant machine is a skill that requires expertise. Otherwise, bended lengths may not be at the desired sizes. As Ramazan Aycan Inc., we provide you with bending services with our hydraulic and electro servo Abkant machines.

Request for a quote

METAL IN LTD

Bulgaria

The modern equipment with CNC machines, which we possess allow us to work sheet iron with thickness till 18 mm and dimensions 1500x3000 mm. These products are with high quality, precise manufacturing and excellent external look. Thank to different machines and equipment (lazer cutting, stamp press, punching, shears, eccentric and hydraulic presses, machine shafts, bending machine for metal sheets straightening , spot welding, robotic MIG-MAG welding, WIG welding, powder coating. The company produce big variety of products as the more important are: Hydraulic reservoirs Metal boxes for electronics Wardrobes Cabinets for instruments Metal cabinets for coffee machines Front panels for professional speakers Fireplaces, burners and barbecues Gun safes and storage of documents Control panels for machines Doors and lids for machines and vacuum cleaners Equipment for stores Lamps for lighting Steps of excavators

Request for a quote

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Metal sheets of various types and thicknesses are produced quickly and at low cost by making millimetric calculations on computer-controlled machines. Thanks to the pressure force that can be applied from 35 tons to 640 tons with press brake bending machines, materials up to 6000 mm in length and up to 20 mm in thickness can be processed.

Request for a quote

PERGEL METAL

Turkey

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Finger bender technology on our X2000NC This is new and revolutionary! Do you know our X2000NC? Then you know the advantages of our variable, modular machine concept. In this new model, we have consistently transferred the finger bending technology of the SPEEDMAX to the X2000NC. This model now combines all the advantages of two bending worlds. By integrating the NC bending technology in combination with our rotary positioning pliers and the servo transfer, the X2000NC is now pushing material speeds to a whole new level. E.g.: Up to 40 parts per minute, each one with up to 6 bendings and 1 press operation is possible

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

KW HYDRAULIK GMBH

Germany

Pressing Pipes Bending Pipes Striping and Peeling of Tube Brochure Tools for Pipeline Construction Drilling of Tubes Cutting and Sawing of Tubes Chamfering Tool for Plastic Tubes

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

These displacement sensors are potentiometric displacement sensors used for direct measurement, testing and monitoring of mechanical displacements. The spring-loaded control rod eliminates the need of coupling with the measurement object. A prerequisite for a very long life duration of the devices is a parallel alignment of the motion direction of the measurement object and the rod. Areas of application are: Displacement on: —Electromagnets —Hydraulic cylinders —Switches and buttons Measurements of: —Deformation —Bending —Press-fits —Feed strokes Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. FEATURES: —Measurement ranges: 0 ... 10 mm to 0 ... 150 mm —Non-linearity up to 0.05 % F.S. —Resolution 0.01 mm —Follower roll on request —Optional with internal spring

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Special machines from Schmale Maschinenbau are equipped with an intelligent combination of technologies. The plant shown above is used to manufacture reinforcement items from solid material with a diameter of 20mm for the building industry. Servo-electric units such as bending slides, presses and finger benders are combined into customer-specific solutions for the production of individual items that can not be produced on standard machines. Schmale offers special machines for wire, tube and strip processing. You can watch various special machines for the production of different forming articles on our YouTube channel. https://www.youtube.com/channel/UCziuQiA3kXBVfH4ecLxQ2JA/videos

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to its high resolution also when measuring long distances, linear displacement measurements up to 900 mm can be carried out. Conversions between rotatory and translation movements through ball screws, wire or cord connections and so on are not necessary for direct displacement measurement. Application fields include: —Electromagnets —Deformations - bending —Pneumatic cylinders —Length tolerances —Press-insertions (longitudinal press-fits) —Feed strokes —Machine hubs —Punch, knee lever or extruder distances —Hydraulic cylinders Due to the technology employed in potentiometric displacement sensors, they always operate with a sliding contact system. Special processes are applied to give the resistance tracks low friction, low tendency to stick/slip, resistance to abrasion and long-term stability. The rod is guided in a low-play floating frontal bearing. This absorbs small angular and parallel displacements.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Advantages of Heating Plates with Square Cartridge Heaters: -> Simple plate manufacture due to rectangular groove geometry, no deep-hole boring -> Simple heater installation by bending and pressing along the plate surface -> Complex plate geometries with bores and openings -> Optimal heat transfer due to 75% surface contact -> No casting with heat conductive compound -> Uniform temperature profiles due to thermally optimized groove layouts/power distribution and utilization of insulation plates -> high process temperatures (up to 450°C in aluminium, up to 700°C in stainless steel) Example "Heated Stamp": D=100 mm out of tempered tool steel up to max. 700°C continuous temperature. Fitted with 2 Square Cartridge Heaters 1500 W/ 230 V, 4,5 x 4,5 mm x 600 mm, with 50 mm unheated at the termination end. Annealed and formable with a nickel sheath, resistant up to 850°C surface temperature. Connection by fibreglass insulated pure nickel high-temperature leads (max. 500°C)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TEKNIK KONTEYNER - WASTE BINS

Turkey

Our metal galvanized waste containers can be specially produced in line with the technical specifications of the product. It can be produced as hot dip galvanized or original galvanized. It can be produced with and without pedal options. Apart from 770 liters, it can also be produced in 770 liters, 660 liters and 400 liters capacities.Body 1.50 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. Base corners are radiused. The assembly of the body sheet and the side sheets together, the 20.00 mm. formed by pressing the sides of the side sheets. It is mounted from the outside to the body sheet with a bent protrusion or lip in width and welded completely, including the radii, without interruption.Body welding and other welds were welded without slag by gas metal arc technique.The body mouth is completely surrounded by a pipe profile.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

Our metal galvanized waste containers can be specially produced in line with the technical specifications of the product. It can be produced as hot dip galvanized or original galvanized. It can be produced with and without pedal options. Apart from 400 liters, it can also be produced in 770 liters, 660 liters and 400 liters capacities. Cover lid color can be in different options.Body 2.00 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. The base has corners and the upper posterior rim is radiused. The assembly of the side sheets made of the same sheet with the body sheet, at least 15.00 mm. wide bent protrusion or lip including all perimeters and radii, with this protrusion, side sheets and body sheet, including external radii, are joined seamlessly by welding.The body welding and other welds are made by using the gas metal arc technique, without slag, by continuous boiling and the body is watertight.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

770 Liter Hot Dip Galvanized Waste Container (Dome Lid Model)Body 1.50 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. Base corners have radius. The assembly of the body sheet and side sheets is made by pressing 20.00 mm on the edges of the side sheets. It is mounted externally to the body sheet with a wide bent protrusion or lip and is completely welded, including the radii, without interruption.The body weld and other welds were welded without slag using the gas arc technique.The body mouth is completely surrounded by a pipe profile.Lift arms and cover connection 2.50 mm. It is welded onto the sheet metal apparatus and screwed onto the body.Lift arms are manufactured in accordance with EN standards. Cover arms 3.00 mm. is.Cover 1.40 mm. It is manufactured from sheet metal as a system that can be opened around its own axis.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

Our metal galvanized waste containers can be specially produced in line with the technical specifications of the product. It can be produced as hot dip galvanized or original galvanized. It can be produced with and without pedal options. Apart from 660 liters, it can also be produced in 770 liters, 660 liters and 400 liters capacities.Body 2.00 mm. It is formed by bending and pressing as a single piece of sheet metal and its strength is increased. The base has corners and the upper posterior rim is radiused. The assembly of the side sheets made of the same sheet with the body sheet, at least 15.00 mm. wide bent protrusion or lip including all perimeters and radii, with this protrusion, side sheets and body sheet, including external radii, are joined seamlessly by welding.The body welding and other welds are made by using the gas metal arc technique, without slag, by continuous boiling and the body is watertight.

Request for a quote

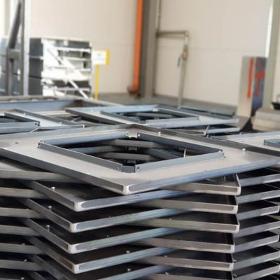

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. - Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. - Sheet bending up to 4000 mm. Capabilities for pipe bending: - Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. - Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. - Sheet bending up to 4000 mm. Capabilities for pipe bending: - Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: Sheet metal bending, CNC tube/pipe bending, And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: Advanced press brakes with wipe dies to allow precise bending with minimal distortion. Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. - Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. - Sheet bending up to 4000 mm. Capabilities for pipe bending: - Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. - Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. - Sheet bending up to 4000 mm. Capabilities for pipe bending: - Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

ARPIAL - METALURGICA LIGEIRA LDA

Portugal

Copper press break partswith bending

Request for a quote

ARPIAL - METALURGICA LIGEIRA LDA

Portugal

Combination of diferent parts, produce from turning, bending, press break and/or welding to result in a final product to the client

Request for a quoteResults for

Bending presses - Import exportNumber of results

86 ProductsCountries

Company type

Category

- Bending - steels and metals (15)

- Bending machine tools (12)

- Pipe and tube fittings - ferrous metal (12)

- Milling - steels and metals (8)

- Laser - cutting and welding machines (6)

- Auditorium seats (4)

- Dustbins, waste bins (4)

- Forming - steels and metals (4)

- Brakes, servo-brakes and accessories (2)

- Industrial sheet metal work (2)

- Milling - machine tools (2)

- Sensors (2)

- Testing equipment (2)

- Compactors and crushers (1)

- Components and parts for small household appliances (1)

- Construction, industrial - contractors (1)

- Cutting - steels and metals (1)

- Electroheat - machines and equipment (1)

- Finished Metal Products (1)

- Furniture for fairs and exhibitions (1)