- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt sanders

Results for

Belt sanders - Import export

IMM MASCHINENBAU GMBH

Germany

The 72711 belt sander offers all benefits of the 72780 series but with only one side. It is made for heavy duty applications. For sitting or standing operation. Variable cutting speeds from 900 to 2,800 Rpm. Optionally with frequency converter.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Rigid machine for heavy duty belt grinding. The machine can be adjusted for horizontal or vertical position. Various options include: Dust extraction, chamfering device, angle guide roller, longitudinal stop.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

The unique belt guide system allows the use of very small belt widths without the belt coming off the roller. The tensioning system ensures continual tension in the belt thus contributing to the safety of the guide system. Available in lever or rotary valve variants. Individual work through the rotatable head. Furthermore it has a protective cap for safe handling.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Suitable for sanding jobs in narrow spaces, recessed corners or on curved surfaces

Request for a quote

EUGEN LÄGLER GMBH

Germany

Worldwide: known, used and admired across the globe! The HUMMEL® is powerful, efficient and reliable. With its optimal dust extraction you are able to work almost dust free. The sophisticated and durable technology for perfect sanding along with its enormous performance quality make the HUMMEL® the undisputed number one machine for sanding wooden floors. It has been convincing craftsmen all over the world for over half a century. It is simultaneously powerful and easy to operate and maintain. Both changing the sanding belt and dismantling the machine are extremely simple. The HUMMEL® can be ordered with or without the powerful LED work light. Applications with the HUMMEL®: The HUMMEL® belt sander is mainly used for sanding wooden floors. It enables precise and economical sanding of both small and large surfaces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

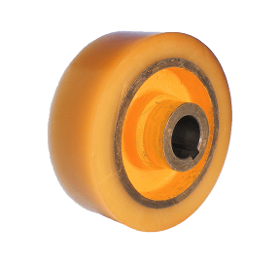

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Wood-Her rollers consist of an aluminum core. Light-colored rubber is used for the coating, in addition to the polyurethane materials that have long been tried and tested in the woodworking industry, and mainly the elastomer Vulkollan®. The core mounting holes have two side holes.As a service, we offer our customers the opportunity to have their used pressure and feed rollers re-upholstered by us. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Tagliabue Model Tag T 22 Year 2007 Condition Used Sanding width 1.350 mm Longitudinal segmented pad 16 mm Workpiece thickness 3 - 150 mm Worktop height from the ground 900mm +/- 20mm Feed speed 5-25 m / min Sanding belt measures 1.350 x 2.620 mm Chevron Belt Dimension 1.350 x 2.250 mm Segment pitch 16.80 mm Orthogonal diameter brush 15 x 200 mm Sanding belt rotation speeds 1-20 m / sec Speed 15 Kw Gearbox 4.0 kW

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Morbidelli Model Author M100 Year 2018 Condition Used Control unit SCM eye-M Axis 5 X-Axis travel 3110 mm Y-Axis travel 1620 mm Z-Axis travel 180 mm Tool changer 28 HSK F63 Bars 6 Vacuum pump 250 m3/h Availability Immediately

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

It is not only being able to change the belt so quickly that makes this belt grinder so distinctive. You can grind an area using the telescopic arm and then change to grinding a point on the rubber roller with the fixed grinding arm. This can be done very easily with a clamping screw. In addition, the machine is available, entirely in accordance with your requirements, with grinding arms for belt widths of 8, 15 or 20 mm. Changing them is easy and requires little effort.

Request for a quoteResults for

Belt sanders - Import exportNumber of results

13 ProductsCountries

Company type