- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- visual inspection

Results for

Visual inspection - Import export

ARODO - PREMIUM POWDER PACKAGING

Belgium

We equip all new machines with a PLC controller and internet connection, enabling our support staff to view the control panel of your machine via remote access. This way we can analyze and adjust the software remotely without a problem. We visually inspect the mechanics of the machine by web cam. Together with you, we're taking major steps toward Industry 4.0.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Pump Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a pump generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing any pump is the inspection. Pump inspections include: Visual inspection Measuring axial positions and clearances Disassembly + visual inspection of parts Dimensional measurements Check of probes and sensors (if present) Oil sampling & check When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope of work may vary, but can include: Cleaning & steaming Sandblasting Preparation of technical drawings for machining by in-house engineering team Machining of parts (bearing housings, rotors, …) Balancing of rotating parts Coating of rotating parts

Request for a quote

MAINTENANCE PARTNERS

Belgium

Gearbox Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a gearbx generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing any gearbox is the inspection. Gearbox inspections include: Visual inspection Measuring axial clearances Measuring gear tooth clearances Disassembly + visual inspection of parts Dimensional measurements Blueprint Oil sampling & check When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope of work may vary, but can include: Cleaning & steaming Sandblasting Preparation of technical drawings for machining by in-house engineering team Machining of parts (bearing housings, rotors, …) Balancing of rotating parts Assembly

Request for a quote

MAINTENANCE PARTNERS

Belgium

Fan Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a fan generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing a fan is the inspection. Fan inspections include: Visual inspection Alignment check Checks of belts and couplings Measurement of axial clearances Disassembly + visual inspection of parts Dimensional measurements When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope of work may vary, but can include: Cleaning & steaming Sandblasting Preparation of technical drawings for machining by in-house engineering team Machining of parts (bearing housings, rotors, …) Balancing of rotating parts Coating of rotating parts Assembly Coating of exterior

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners provides services on various types of blowers, for example: Vacuum blowers Lobes Screws Centrifugal blowers High Vacuum Boosters (HVB) All brands We offer repairs on blowers of all brands, including Aerzen, Dresser-Rand (Roots) and Ebara. Blower Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a roots blower generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing a blower is the inspection. Blower inspections include: Visual inspection Measuring axial and radial clearances Measuring of backlash Disassembly + visual inspection of parts Dimensional measurements Blueprint Oil sampling & check When the inspection is finished, an inspection report is drawn up with recommendations for repair.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAINTENANCE PARTNERS

Belgium

Types of Industrial Fans Maintenance Partners provides services on various types of fans, for example: Centrifugal Axial Fan units (fan + motor) Directly driven Indirectly driven (chain or belt) Fan Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a fan generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing a fan is the inspection. Fan inspections include: Visual inspection Alignment check Checks of belts and couplings Measurement of axial clearances Disassembly + visual inspection of parts Dimensional measurements When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope of work may vary, but can include: Cleaning & steaming Sandblasting Preparation of technical drawings for...

Request for a quote

MAINTENANCE PARTNERS

Belgium

Types of Blowers Maintenance Partners provides services on various types of blowers, for example: Vacuum blowers Lobes Screws Centrifugal blowers High Vacuum Boosters (HVB) All brands We offer repairs on blowers of all brands, including Aerzen, Dresser-Rand (Roots) and Ebara. Blower Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a roots blower generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing a blower is the inspection. Blower inspections include: Visual inspection Measuring axial and radial clearances Measuring of backlash Disassembly + visual inspection of parts Dimensional measurements Blueprint Oil sampling & check When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners has built up decades of world-class expertise in repairing generators. We provide services on a broad range of equipment: Salient pole and Turbo rotors From small (kVA) to large (MVA) power High voltage and Low voltage Air cooled up to Hydrogen cooled Generator Services & Repairs Our services range from standard inspections, revision and repair of generators to full (re)winding. We can perform our services in our workshop or onsite. The best repair approach is selected in cooperation with the customer and the scope of a minor and major inspection is determined. Minor inspection Disconnecting equipment and electrical insulation measurements Check of temperature propes, heating system and instrument transformers Visual inspection Inspection of the coolers Check of rotating diodes, slip rings and excitation system Check of grounding brushes

Request for a quote

MAINTENANCE PARTNERS

Belgium

Types of Generators Maintenance Partners has built up decades of world-class expertise in repairing generators. We provide services on a broad range of equipment: Salient pole and Turbo rotors Emergency Power Units From small (kVA) to large (MVA) power High voltage and Low voltage Air cooled up to Hydrogen cooled Generator Services & Repairs Our services range from standard inspections, revision and repair of generators to full (re)winding. We can perform our services in our workshop or onsite. The best repair approach is selected in cooperation with the customer and the scope of a minor and major inspection is determined. Minor inspection Disconnecting equipment and electrical insulation measurements Check of temperature propes, heating system and instrument transformers Visual inspection Inspection of the coolers Check of rotating diodes, slip rings and excitation system Check of grounding brushes Major overhaul Major overhaul can include the following tasks: Detailed...

Request for a quote

MAINTENANCE PARTNERS

Belgium

Assessment & Maintenance Plan Transformers are low maintenance, but not free of maintenance. To determine the maintenance need of your transformer(s), Maintenance Partners offers an assessment that consists of visual inspections, oil sampling, thermography and electrical measurements. The assessment is the foundation for a maintenance plan in which the condition and priority of each transformer are decisive for the maintenance frequency and needs. Transformatoren Maintenance Partners - Preventief Onderhoud - StaalnamePreventive Maintenance For a safe and reliable operation of transformers, preventive maintenance is a must. This detects problems at an early stage and can prevent further deterioration. Preventive maintenance includes the following tests: Oil sampling + analysis (Oil quality, PCB, furan detection, moist level, …) Electrical measurements (Insulation resistance, Winding resistance, Transformer Turn Ratios, SFRA-Sweep Frequency Response Analysis, IDAX- Tgδ, …)

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners offers a full maintenance solution for oil filled and dry transformers. We offer services for distribution and power transformers of all brands, including: ACEC BBC Helmke Siemens AEG Brush Holec Smit Alstom France Transfo I.E.O. Stromberg ASEA G.E.C. Pauwels / CG Trafo Union Assessment & Maintenance Plan Transformers are low maintenance, but not free of maintenance. To determine the maintenance need of your transformer(s), Maintenance Partners offers an assessment that consists of visual inspections, oil sampling, thermography and electrical measurements. The assessment is the foundation for a maintenance plan in which the condition and priority of each transformer are decisive for the maintenance frequency and needs. Preventive Maintenance For a safe and reliable operation of transformers, preventive maintenance is a must. This detects problems at an early stage and can prevent further deterioration. Preventive maintenance includes the following tests: Oil.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

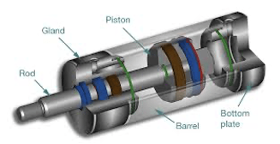

Non-rotating asset components seldom receive the routine surveillance they need Hydraulic systems represent another way industry converts electricity to mechanical energy. A pump, normally powered by an electric motor, moves hydraulic fluid through a system. The system is typically made up of a reservoir to hold the hydraulic fluid, high pressure lines to carry the fluid, control valves that ensure the fluid is sent where needed, relief valves for safety, and cylinders to produce mechanical energy. The pump and motor receive attention while the balance of the system is run-to-failure. Ultrasound testing could change this lackadaisical approach; especially considering its versatility, ease of use, and applicability to most hydraulic defects. External and Internal Leaks External leaks can often be found by visual inspection. Some external leaks, like a ruptured hose or fitting, are easy to spot. Simply follow the trail of spilled oil. Others are not so obvious.

Request for a quoteResults for

Visual inspection - Import exportNumber of results

13 ProductsCompany type