- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal conductivity

Results for

Thermal conductivity - Import export

RITTAL

Belgium

Aluminium enclosure, high thermal conductivity for optimum passive heat dissipation. Low weight coupled with high stability. Protection category IP 65 to IEC 60 529. CP Compact Panel, for front panel BH 520x400 mm, installation depth 74 mm, Extruded aluminum section, Support arm connection 120x65 mm, Hinged rear panel with screw lock

Request for a quote

KURARAY (EVAL EUROPE N.V.)

Belgium

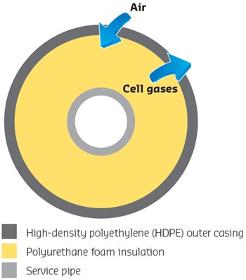

Decreasing insulation efficiency The insulation efficiency of PUR foam decreases over time as air permeates in and cell gasses permeate out of the pipe structure, increasing thermal conductivity. Oxygen permeation can also lead to oxidative degradation of the PUR-foam insulation itself. This reduces the adhesion between the PUR-foam and inner pipe, weakening the structure and compromising the mechanical integrity of the entire pipe system. Maintained efficency and improved performance with EVAL™ With EVAL™ the insulation efficiency of the PUR foam is maintained, avoiding an increase in thermal conductivity . Oxygen ingress that can degrade the PUR-foam insulation is also sharply reduced. EVAL™ provides good adhesion to the PUR-foam without additional surface treatement. For more information, please contact Cynthia Teniers

KURARAY (EVAL EUROPE N.V.)

Belgium

Many pre-insulated pipes use rigid polyurethane foam and a HDPE casing. Over time, the insulation efficiency of the pipe structure decreases, caused by the permeation of air (oxygen, nitrogen) into the foam cells and the diffusion of cell gases (blowing agent, carbondioxide) out of the foam cells. The insulation efficiency of PUR foam decreases as air permeates in and cell gasses permeate out of the pipe structure, increasing thermal conductivity. Oxygen permeation can also lead to oxidative degradation of the PUR-foam insulation itself. This reduces the adhesion between the PUR-foam and inner pipe, weakening the structure and compromising the mechanical integrity of the entire pipe system.

DK CERAMIC CIRCUITS

Belgium

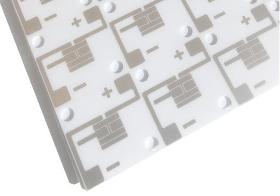

When you are looking for substrates for electronic circuits with a high thermal conductivity and a low expansion coefficient (CTE), ceramic pcb will be your preferred choice of material. Today ceramics are already widely used as substrates in many microelectronic components and power LED packages and more and more they are replacing entire printed circuit boards reducing complexity in design and manufacturing while increasing performance. Examples are Chip-on-board (COB) modules, High power circuits, proximity sensors, battery drivers for EVs, … .

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Thermal conductivity - Import exportNumber of results

4 ProductsCompany type