- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- testing

Results for

Testing - Import export

TELEDYNE ICM

Belgium

With their large active areas, shock-absorbing hard protective sleeves, and light-weight form factor, the new GO-SCAN digital panels have been designed to meet NDT technicians’ requirements in terms of ease-of-use, ruggedness, and image quality.

Request for a quote

TELEDYNE ICM

Belgium

With their large active areas, shock-absorbing hard protective sleeves, and light-weight form factor, the new GO-SCAN digital panels have been designed to meet NDT technicians’ requirements in terms of ease-of-use, ruggedness, and image quality.

Request for a quote

TELEDYNE ICM

Belgium

With a resolution of 49.5 µm for an active area of 230×290 mm (9×11.4 in), the Go-Scan 2329 is the only detector on the market with such a high resolution to image size ratio. The image quality reaches class B (ISO 17636-2) for almost all your applications. High definition, user-friendly, light-weight, real-time feedback, shock absorbing! Featuring Teledyne DALSA’s high-resolution CMOS detector, and the lightest x-ray generator on the market, Teledyne ICM’s CP SERIES, the Go-Scan solution is without a doubt the all-around NDT solution when it comes to image quality, ease of use, handiness, and reliability.

Request for a quote

TELEDYNE ICM

Belgium

For the first time ever, Teledyne ICM and Teledyne DALSA, two of the most advanced x-ray solution providers in the world, unite forces and reveal the first Integrated Digital Portable X-Ray Solution for Non-Destructive Testing… ever! High definition, User-friendly, Light-weight, Real-time feedback, Shock absorbing! By focusing on the end-user as the starting point of this incredible collaboration, we created a high-tech digital x-ray solution entirely designed around you! Featuring Teledyne DALSA’s high-resolution CMOS detector, and the lightest x-ray generator on the market, Teledyne ICM’s CPSERIES, the Go-Scan solution is without a doubt the all-around NDT solution when it comes to image quality, ease of use, handiness, and reliability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SDT ULTRASOUND SOLUTIONS

Belgium

Detecting mechanical faults before they stop production Bearing and Machine Maintenance Industry runs on machinery. Bearings, pumps, electric motors, compressors, presses, gearboxes and much more. All of which can break unexpectedly, causing production to stop. When production stops your organization loses money. Few bearings make it to the end of their engineered lifecycle. This is due to poor workmanship, bad lubrication practices and neglect. Problems can even arise right after installation due poor installment of the machine. No two machines are the same. Across industry, machines operate under different loads, climates and conditions, making their maintenance requirements unpredictable. Many machines are still maintained on calendar based PM’s, while others are run-to-failure. Both strategies are wasteful.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

SDT was the first to pioneer on ultrasound-based hatch cover weathertightness testing on board of ships back in the late 1980s. Together with MacGregor, Lloyds Register of Shipping and IMCS, SDT was able to put ultrasound testing of hatch covers on the world map and make it the preferred method for testing hatch covers by charterers, shippers, P&I insurers and stakeholders in the marine industry. Another first position for SDT is that further development of the tightness testing equipment resulted in SDT launching the world’s first Class type approved and bespoke SHERLOG product range in 2000. Ever since, the SDT SHERLOG equipment became a symbol of reliable and professional hatch cover testing. As no solution is complete without training, SDT & IMCS developed the first and only training course for ultrasound testing of hatch covers in line with the IACS UR Z17 criteria.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

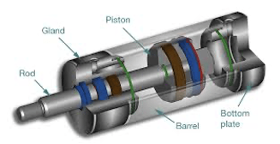

Non-rotating asset components seldom receive the routine surveillance they need Hydraulic systems represent another way industry converts electricity to mechanical energy. A pump, normally powered by an electric motor, moves hydraulic fluid through a system. The system is typically made up of a reservoir to hold the hydraulic fluid, high pressure lines to carry the fluid, control valves that ensure the fluid is sent where needed, relief valves for safety, and cylinders to produce mechanical energy. The pump and motor receive attention while the balance of the system is run-to-failure. Ultrasound testing could change this lackadaisical approach; especially considering its versatility, ease of use, and applicability to most hydraulic defects. External and Internal Leaks External leaks can often be found by visual inspection. Some external leaks, like a ruptured hose or fitting, are easy to spot. Simply follow the trail of spilled oil. Others are not so obvious.

Request for a quoteResults for

Testing - Import exportNumber of results

16 ProductsCompany type