- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting machines

Results for

Cutting machines - Import export

VAN EYCKEN - METAL CONSTRUCTION

Belgium

You can rely on us for traditional laser work. We offer our advanced flatbed laser services, powered by the powerful FinPower L6 laser. This reliable machine takes your sheet metal processing to new heights, with the capability to cut and shape sheet material up to 15 mm thick with precision. The impressive power of our L6, driven by a 4 kW CO2 laser, allows you to maximize your projects. Additionally, we offer the flexibility to engrave unique part numbers, giving you control over the identification of your pieces. In our workshop, your pieces can be further processed with machine sanding and deburring, eliminating the need for post-processing. This allows us to provide a complete solution for your projects. Discover the versatility of our laser services and the comprehensive support we offer.

Request for a quote

VAN EYCKEN - METAL CONSTRUCTION

Belgium

At Van Eycken in Tienen, we introduce our advanced laser services, powered by our state-of-the-art FG-400 NEO tube laser from MAZAK. This machine, launched in 2022, is designed for high-quality 3D cutting of tubes, pipes, and structural material up to 15 meters in length. With various advanced technologies, the FG-400 NEO offers unparalleled operability and flexibility, resulting in highly efficient cutting work. The 3D cutting head with dual axis can handle a wide range of materials at any desired angle. The 4-jaw chuck system ensures stability and precision during cutting by preventing material deformation. The FG-400 NEO stands out by performing multiple processes in one machine, from 3D cutting to drilling and tapping. This versatility provides you with a complete solution for your laser processing needs, saving time and reducing costs.

Request for a quote

SOPEM

Belgium

Year - 1970 Working from blanks - 1 inside + 2 outside flexo print units - window station - no outside side flaps - dextrine gumming

Request for a quote

LVD

Belgium

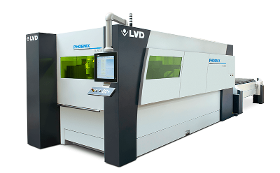

The Phoenix fiber laser cutting machine is an all-around performer. It has the flexibility to expertly cut standard steels and non-ferrous materials in a range of thicknesses and combines high machine dynamics, intuitive machine operation, and advanced automation options to maximize productivity no matter the application. The inherent benefits of fiber laser technology make Phoenix cost effective to maintain and operate. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Processes different sheet thicknesses without manual intervention Advanced cutting head handles thicker materials “On the fly” cutting in light gauge material Integrated Siemens CNC control and drive system offers high reliability TOUCH-L touch screen graphical user interface control is intuitive and simple to use Automatic shuttle table maximizes uptime PERFORMANCE-ENHANCING OPTIONS CADMAN-L programming software MOVit Automation: TAS, WAS, Compact Tower

Request for a quote

SOPEM

Belgium

Year - 1991 Working from blanks - 1 inside + 2 outside flexo print units - window station - dextrine gumming

Request for a quote

SOPEM

Belgium

Year - 1988 - width : 120 cm - 6 colours - stack type

Request for a quote

SOPEM

Belgium

Year - 1980 Sheeter with deep-pile delivery. Working width: 107 cm - cut-off length from 40 to 100 cm

Request for a quote

LVD

Belgium

LVD’s tube cutting machines are designed for high production tube fabrication. They provide efficient processing of round, rectangular, square or other standard tube profiles at optimal speeds using a fiber laser. The integration of leading-brand components assures you of top performance and high reliability. Machines are engineered for quick set up of different tube sizes and built for ease of service and maintenance. KEY FEATURES Automatic set-up and run Round, rectangular, square and other profiles are standard Standard components for easy service and maintenance Random standard length 7-position magazine feed 2kW resonator CADMAN-T programming software PERFORMANCE-ENHANCING OPTIONS Bundle feed Seam detection system Outfeed conveyor system Automated nesting for best utilization of materials CADMAN-T embedded advanced programming software

Request for a quote

LVD

Belgium

TL 8525 is a high-capacity tube laser cutting machine designed for top productivity. It handles lengths up to 8500 mm and diameters up to 250 mm round or square. The TL 8525 comes equipped with leading-edge features, including a 45-degree tilt-axis cutting head with NC-Focus, 6-position front loader, 2 kW IPG fiber laser, and a large X-axis cutting head range of 1190 mm to maximize material usage. KEY FEATURES Accommodates tube and profile lengths up to 8500 mm, diameters up to 250 mm High-performance cutting head with NC-Focus and bevel function +/- 45 degrees Magazine style 6-position automatic tube load system Leading edge detection for variable tube lengths Automatic bow detection and compensation system Automatic twist compensation system Outfeed tube support with accompanying conveyor table Siemens CNC control is PC-based with touchscreen PERFORMANCE-ENHANCING OPTIONS 4 kW fiber laser source 6100 mm outfeed extension Part evacuation conveyor Automatic weld seam detection

Request for a quote

LVD

Belgium

MOVit Warehouse Automation System (WAS) provides the ultimate in automatic material storage and retrieval with a customizable number of tower storage units beginning with a minimum of four towers, in a single or double row configuration. WAS keeps sheets in continuous flow for uninterrupted production and full lights-out operation, and can be connected to multiple laser cutting machines. KEY FEATURES Allows full lights-out production for high productivity Can feed multiple lasers Customizable number of towers, starting at a minimum of four towers Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Direct unload station Input/Output (I/O) station Simple output station Extended output station MODELS Available for Phoenix and Electra series (WAS 3015 and WAS 4020)

Request for a quote

LVD

Belgium

MOVit Tower Automation System (TAS) is a single or double tower storage system for integration with one or two laser cutting machines in 3015, 4020 or 6020 formats. Available in 16 possible configurations, TAS offers a continuously-ready material supply to keep machine output at its peak. An optional direct unload station allows processed work pieces to be offloaded for sorting or secondary processing. KEY FEATURES Efficient storage and retrieval of raw materials Continuous material flow for uninterrupted and lights-out production Optimized use of floor space Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Direct unload station Input/Output (I/O) tower station 16 possible system configurations MODELS Available for Phoenix and Electra series (TAS 3015, TAS 4020 and TAS 6020) Specifications 3-ton capacity per pallet (5-ton for 6020) Up to 63 pallets, depending on system configuration Stack height of 90 mm

Request for a quote

LVD

Belgium

The Compact Tower (CT-L) provides full capabilities for loading, unloading and storage of raw material and finished parts. This enables automated production from stored raw material to stacked finished parts. The CT-L system creates a productive, flexible manufacturing cell capable of operating “lights out.” An intuitive touch screen graphical user interface ensures operation of the CT-L is fast and efficient. KEY FEATURES Creates flexible manufacturing cell Pallet construction designed for compact set up and convenient forklift manipulation Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading Touch screen graphical user control is intuitive and simple to use MODELS Available for Phoenix FL-3015 and Electra FL-3015

Request for a quote

LVD

Belgium

The FA-L automatic load/unload system is designed to keep pace with today’s high-speed fiber and CO2 laser cutting machines. It can unload a processed sheet and load the next sheet in just 40 seconds. By keeping a continuous, uninterrupted production flow, the system maximizes machine throughput. The FA-L is ideal for large-volume applications with common material type, thickness and size. KEY FEATURES Automated production from stored raw material to stacked finished part Fast loading system Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading Intuitive touch screen graphical user interface PRODUCTIVITY-ENHANCING OPTIONS Second loading pallet Belt-driven unload system for scratch-free unloading Full integration with an existing warehouse MODELS Available for Sirius Plus, Electra and Phoenix systems

Request for a quote

LVD

Belgium

MOVit Load-Assist automation (LA) offers two systems to increase laser cutting productivity: LA Load automatically transfers unprocessed sheets quickly and efficiently to the cutting machine shuttle table. LA Load/Unload automatically loads material and, during unmanned production, unloads cut sheets to an unloading station or a conveyor. KEY FEATURES Cost-effective automation Simple and efficient material handling without operator intervention Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Load/unload tables MODELS LA Load available for Lynx, Phoenix and Electra systems (LA 3015 and LA 4020) LA Load/Unload offered for Phoenix and Electra series (LA 3015 and LA 4020)

Request for a quote

LVD

Belgium

YSD LaserONE provides the key benefits of fiber laser cutting technology but eliminates the extras that increase machine cost and complexity. The LaserONE fiber laser cutting machine is designed for dependable performance and ease of use, and provides a quick return on investment. LaserONE is designed, manufactured, sold and serviced by LVD, backed by the LVD worldwide service and support network. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Cutting head with NC focus, automatic focal adjustment and crash protection Designed for easy access to cutting table and scrap containers PC-based Siemens CNC control, servo motors and drives PERFORMANCE-ENHANCING OPTIONS Load-Assist automation in load-only or load/unload configuration MODELS YSD LaserONE 3015

Request for a quote

LVD

Belgium

COST-EFFICIENT FIBER LASER CUTTING MACHINE The Lynx allows easy entry into fiber laser cutting. With a modest investment, you can benefit from the flexibility and productivity of fiber laser technology. Cut ferrous and non-ferrous materials reliably with excellent cut quality and at three times the speed of a CO2 laser, achieving low per part cost. Enjoy high uptime with a virtually maintenance-free laser source, high wall plug efficiency, and very low operating costs. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass IPG fiber laser source is virtually maintenance-free High wall plug efficiency of 40% Integrated Siemens CNC control and drive system ensures high reliability Automatic pallet changeover for efficient sheet loading and unloading in just 35 seconds PERFORMANCE-ENHANCING OPTIONS MOVit Automation: Load-Assist CADMAN-L programming software MODELS Lynx FL-3015 Lynx FL-4020

Request for a quote

LVD

Belgium

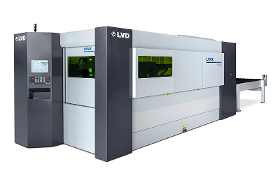

FAST, FLEXIBLE FIBER LASER CUTTING MACHINE Realize the full benefits of fiber laser cutting with Electra, our top-of-the-line system that offers ultra-high-speed processing and high flexibility. Electra is designed to cut as fast as the thermal process allows and is able to process a wide range of ferrous and non-ferrous metals. LVD’s touch screen control and user interface make the system easy to set up and operate. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Fast 2G acceleration during cutting “On the fly” cutting in light gauge material IPG YLS fiber laser source is virtually maintenance-free High wall plug efficiency of 40% TOUCH-L touch screen graphical user interface control is intuitive and simple to use Integrated automatic shuttle bed system PERFORMANCE-ENHANCING OPTIONS Multiple kW options MOVit Automation: TAS, WAS, Compact Tower (CT-L), Flexible Automation (FA-L), Load-Assist CADMAN-L programming software

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SOPEM

Belgium

Year - 1975 - width : 1400 mm - maximum diameter at unwinding : 1000 mm - maximum diameter at rewinding : 320 mm - cutting by razor blade or circular knife

Request for a quote

SOPEM

Belgium

Year - 1978 Width : 100 cm - diameter at unwinding : 80 cm - diameter at rewinding : 55 cm

Request for a quote

SOPEM

Belgium

Year - 1990 Stack type - width : 1040 mm - 6 colour

Request for a quote

SOPEM

Belgium

Year - 1990 Stack type - width : 600 mm - 6 colour

Request for a quote

SOPEM

Belgium

Year - 1960 Conical bag machine with a 2-color flexo printer

Request for a quote

SOPEM

Belgium

Year - 1972 3-color flexo printer - width 80 cm - to be coupled

Request for a quote

SOPEM

Belgium

Year - 1983 Reel-to-reel 6-colour flexo printer with central drum. Paper width : 132 cm - printing width : 127 cm - Print repeat : from 30 to 80 cm

Request for a quote

SOPEM

Belgium

Year - 1975 4-colour flexo printer to be coupled to bag machine

Request for a quote

SOPEM

Belgium

Year - 1994 Sack length: 33 ? 80 cm Sack width: 30 ? 60 cm Rewinder PP ? strap 5 mm Diameter of sack reel max. 1.500 mm Sacks per reel: 2.500 ? 3.500 pieces

Request for a quote

SOPEM

Belgium

Year - 1965 Bag width : 7 - 19 cm - bag length : 12 - 28.5 cm - 2 ply - photocell - bottom patch

Request for a quoteResults for

Cutting machines - Import exportNumber of results

113 ProductsCountries

Company type