- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser technology

Results for

Laser technology - Import export

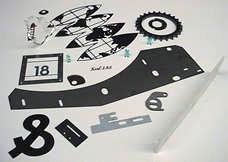

MECANIC SYSTEMS SA

Belgium

Mecanic Systems was one of the first in Belgium to put their faith in this revolutionary "LASER" blanking technology. A LASER transforms electrical energy into a laser beam oriented by mirrors that can be focused on a surface diameter of less than 0.2mm. As a factory tool, the laser is rapid, free from wear and tear and other constraints and of high precision. . This technology has the advantage of having no limit in terms of the geometry of the item, presents no deformation or relief in terms of cutting, and is accurate to +/- 0.1mm. Mecanic Systems, in a permanent state of evolution, regular invests in machines that are increasingly efficient, reliable, rapid and productive thanks to their automatic loading and unloading systems.

Request for a quote

SHAPEYOURGLASS

Belgium

Glass cutting is a complex process requiring innovative technologies. Our lasercut technique allows many possibilities in terms of shape whether straight or rounded. Moreover, this step does not alter the resistance of the glass and provides highquality straight edges finish.

Request for a quote

SHAPEYOURGLASS

Belgium

Glass is a material widely used in the medical field for many of its properties. Some specific tools or accessories require a madetomeasure shape, and our laser cutting technology is here to deliver to those special requirements.

Request for a quote

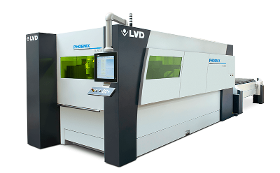

LVD

Belgium

The Phoenix fiber laser cutting machine is an all-around performer. It has the flexibility to expertly cut standard steels and non-ferrous materials in a range of thicknesses and combines high machine dynamics, intuitive machine operation, and advanced automation options to maximize productivity no matter the application. The inherent benefits of fiber laser technology make Phoenix cost effective to maintain and operate. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Processes different sheet thicknesses without manual intervention Advanced cutting head handles thicker materials “On the fly” cutting in light gauge material Integrated Siemens CNC control and drive system offers high reliability TOUCH-L touch screen graphical user interface control is intuitive and simple to use Automatic shuttle table maximizes uptime PERFORMANCE-ENHANCING OPTIONS CADMAN-L programming software MOVit Automation: TAS, WAS, Compact Tower

Request for a quote

LVD

Belgium

Combination technology offers complete part processing for flexible manufacturing. The punch press handles high-speed punching and forming operations. The fiber laser delivers high-quality cutting of outer contours, intricate inner contours and can be used for material etching. Choose from single-head (Strippit PX-L) or turret style (Strippit V/VT-L), 200 or 300 kN configurations, 3- or 4-kW fiber laser in a modern, energy-efficient machine design from the industry’s punch-laser technology pioneer. KEY FEATURES 20 direct-drive indexable tool stations (Strippit PX-L) 40/48 turret stations (Strippit V/VT-L) Fully programmable punching cycles (Strippit PX-L) High-speed punching, forming, bending and tapping Laser cutting of unique shaped holes or contours, material etching Fanuc 3- or 4-kW fiber laser Precitec ProCutter auto-focus cutting head Next-generation rack and pinion drive system eliminates backlash, provides accurate positioning

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

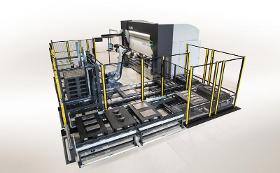

LVD

Belgium

Ulti-Form takes automated bending a step forward with a ToolCell-inspired automated tool changing press brake using a built-in tooling warehouse and equipped with Easy-Form® Laser adaptive bending technology. Programming for both the press brake and robot is handled offline with no robot teaching needed. An auto-adaptive robot gripper designed by LVD automatically adjusts to the workpiece size, allowing different part geometries to be processed without a gripper change. KEY FEATURES Automated tool changer press brake reduces setup time Easy-Form® Laser adaptive bending technology ensures part accuracy KUKA robot and press brake work in synergy to minimize changeover time Programming is handled completely offline, no robot teaching Auto-adapting, universal gripper handles part sizes from 50 x 100 mm up to 1200 x 800 mm High productivity in a compact space, including three input pallets and output zone for up to 10 pallets Automated pallet dispenser and conveyor

Request for a quote

LVD

Belgium

YSD LaserONE provides the key benefits of fiber laser cutting technology but eliminates the extras that increase machine cost and complexity. The LaserONE fiber laser cutting machine is designed for dependable performance and ease of use, and provides a quick return on investment. LaserONE is designed, manufactured, sold and serviced by LVD, backed by the LVD worldwide service and support network. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Cutting head with NC focus, automatic focal adjustment and crash protection Designed for easy access to cutting table and scrap containers PC-based Siemens CNC control, servo motors and drives PERFORMANCE-ENHANCING OPTIONS Load-Assist automation in load-only or load/unload configuration MODELS YSD LaserONE 3015

Request for a quote

DK CERAMIC CIRCUITS

Belgium

Ceramic prined circuit board feature many advantages over metal core and FR4 circuit boards as they combine excellent thermal characteristics with low a expansion. They are also suitable for multilayer applications, show lower deformation, warpage and operate under higher temperatures. Elite advanced technologies is your partner for ceramic substrates and circuit boards. Thanks to our large laser facilities and patented printing technology we are able to accomodate both very tight tolerances as well as high volume production at a high quality.

Request for a quoteResults for

Laser technology - Import exportNumber of results

9 ProductsCountries

Company type