- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation

Results for

Automation - Import export

GEMONE

Belgium

Stay informed about the precise location of your machines at all times, whether they're inside your facility, on your premises, or in transit. Each machine is equipped with a durable tracker that maintains continuous communication with the GemOne platform.

Request for a quote

GEMONE

Belgium

You put all of our solutions and guides and manuals on https://www.gemone.com/en/guides-manuals/ including Sapphire installation guides, Onyx installation guides, and Add-on installation guides.

Request for a quote

GEMONE

Belgium

Streamline your operations by incorporating the advantages of GemOne into your workflow, enhancing fleet efficiency. Seamlessly connect your rental software or ERP with automatic notifications to schedule periodic maintenance. Our seasoned team is prepared to work alongside you in integrating GemOne with your current company systems. Whether you have a dedicated IT team or wish to expand your integrated platform independently, we guide you in the right direction.

Request for a quote

GEMONE

Belgium

This service includes connection to any type of machine, integration with your current hardware and software, providing end-user training during onboarding, and swiftly and securely handle your data in the Cloud. This allows you to concentrate entirely on your business.

Request for a quote

GEMONE

Belgium

Proximity Warning, powered by Lopos, is an optional add-on crafted to elevate workplace safety in warehouses and while using forklifts. This 360° proximity warning system delivers crucial alerts and actionable insights to mitigate incidents and cultivate a secure work environment. By minimising impacts between forklifts, the system aids in averting damage and downtime, safeguarding both your equipment and employees. Additionally, it serves as a vital measure to reduce collisions between forklifts and pedestrians, ensuring a workplace that prioritises safety. Proximity Warning delivers detailed reports on near-misses. This information enables the identification of operators and pedestrians prone to accidents, facilitating proactive measures to enhance overall safety.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LVD

Belgium

MOVit Warehouse Automation System (WAS) provides the ultimate in automatic material storage and retrieval with a customizable number of tower storage units beginning with a minimum of four towers, in a single or double row configuration. WAS keeps sheets in continuous flow for uninterrupted production and full lights-out operation, and can be connected to multiple laser cutting machines. KEY FEATURES Allows full lights-out production for high productivity Can feed multiple lasers Customizable number of towers, starting at a minimum of four towers Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Direct unload station Input/Output (I/O) station Simple output station Extended output station MODELS Available for Phoenix and Electra series (WAS 3015 and WAS 4020)

Request for a quote

LVD

Belgium

The FA-L automatic load/unload system is designed to keep pace with today’s high-speed fiber and CO2 laser cutting machines. It can unload a processed sheet and load the next sheet in just 40 seconds. By keeping a continuous, uninterrupted production flow, the system maximizes machine throughput. The FA-L is ideal for large-volume applications with common material type, thickness and size. KEY FEATURES Automated production from stored raw material to stacked finished part Fast loading system Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading Intuitive touch screen graphical user interface PRODUCTIVITY-ENHANCING OPTIONS Second loading pallet Belt-driven unload system for scratch-free unloading Full integration with an existing warehouse MODELS Available for Sirius Plus, Electra and Phoenix systems

Request for a quote

LVD

Belgium

MOVit Load-Assist automation (LA) offers two systems to increase laser cutting productivity: LA Load automatically transfers unprocessed sheets quickly and efficiently to the cutting machine shuttle table. LA Load/Unload automatically loads material and, during unmanned production, unloads cut sheets to an unloading station or a conveyor. KEY FEATURES Cost-effective automation Simple and efficient material handling without operator intervention Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Load/unload tables MODELS LA Load available for Lynx, Phoenix and Electra systems (LA 3015 and LA 4020) LA Load/Unload offered for Phoenix and Electra series (LA 3015 and LA 4020)

Request for a quote

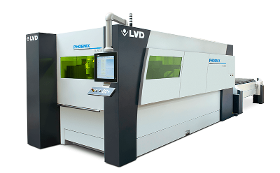

LVD

Belgium

The Phoenix fiber laser cutting machine is an all-around performer. It has the flexibility to expertly cut standard steels and non-ferrous materials in a range of thicknesses and combines high machine dynamics, intuitive machine operation, and advanced automation options to maximize productivity no matter the application. The inherent benefits of fiber laser technology make Phoenix cost effective to maintain and operate. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Processes different sheet thicknesses without manual intervention Advanced cutting head handles thicker materials “On the fly” cutting in light gauge material Integrated Siemens CNC control and drive system offers high reliability TOUCH-L touch screen graphical user interface control is intuitive and simple to use Automatic shuttle table maximizes uptime PERFORMANCE-ENHANCING OPTIONS CADMAN-L programming software MOVit Automation: TAS, WAS, Compact Tower

Request for a quote

LVD

Belgium

MOVit Tower Automation System (TAS) is a single or double tower storage system for integration with one or two laser cutting machines in 3015, 4020 or 6020 formats. Available in 16 possible configurations, TAS offers a continuously-ready material supply to keep machine output at its peak. An optional direct unload station allows processed work pieces to be offloaded for sorting or secondary processing. KEY FEATURES Efficient storage and retrieval of raw materials Continuous material flow for uninterrupted and lights-out production Optimized use of floor space Highly reliable automated production PRODUCTIVITY-ENHANCING OPTIONS Direct unload station Input/Output (I/O) tower station 16 possible system configurations MODELS Available for Phoenix and Electra series (TAS 3015, TAS 4020 and TAS 6020) Specifications 3-ton capacity per pallet (5-ton for 6020) Up to 63 pallets, depending on system configuration Stack height of 90 mm

Request for a quoteResults for

Automation - Import exportNumber of results

11 ProductsCountries

Company type