- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearings for alternators

Results for

Bearings for alternators - Import export

IGUS® GMBH

Germany

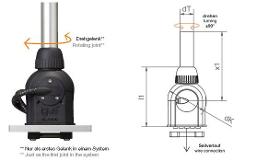

DOF* rotating Can only be used as the first joint in a system. Material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) *degree of freedom Balls: DOF* rotating Can only be used as the first joint in a system. Material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) *degree of freedom Balls:

Request for a quote

IGUS® GMBH

Germany

Oscillatory robolink® joint - optional with angle sensors material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) Balls: Oscillatory robolink® joint - optional with angle sensors material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) Balls:

Request for a quote

IGUS® GMBH

Germany

xiros® A500 heat Plastic ball bearings for high temperatures up to +150°C Product range xiros® A500 chemistry Plastic ball bearings with high resistance against chemicals. Product range xiros® A500 economical alternative Plastic ball bearings as an economical alternative. Product range xiros® A500 wear resistant Plastic ball bearing with wear resistance improved by factor 3. Product range Cage: PEEK PA Balls ES = stainless steel GL = glas PAI = Polymer xiros® A500 heat Plastic ball bearings for high temperatures up to +150°C Product range xiros® A500 chemistry Plastic ball bearings with high resistance against chemicals. Product range xiros® A500 economical alternative Plastic ball bearings as an economical alternative. Product range xiros® A500 wear resistant Plastic ball bearing with wear resistance improved by factor 3. Product range

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Slim Type Crossed Roller Bearings are slim bearings having a small outside diameter against the bore diameter and a narrow width. In addition, types with cage, types with separator, and full complement types are available, which can be selected according to the intended use. Crossed Roller Bearings are compact bearings with their rollers alternately crossed at right angles to each other between inner and outer rings. The orthogonal array of rollers allows the bearing to handle complex loads simultaneously from any direction, which makes assembly possible without needing to worry about load direction.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ATS ELECTRO-LUBE EUROPE

United Kingdom

- Pressure to 200 bar - Run feed lines up to 60m long - Service up to 12 points from 1 Oiler - Easy to refill 1.4L reservoir - Built in lubricant level sensor - Control optins & AC/DC power available - Removable contaminant screen - Weatherproof, dustproof & ATEX certified The Titan Oiler is a specialised automatic oil lubrication system. Using our patented Ultimate technology the Titan Oiler is the most powerful automatic oil lubricator on the market. Generating 200 bar pressure, the Oiler can be installed to feed up to 12 points. or bearings. as an alternative to expensive centralised lubrication systems, This automatic lubricator to service lubrication points up to 60m away, allowing maintenance operatives to service hazardous lube points from a safe working area. Cut maintenance costs, extend machinery life, and improve safety. Call ATS today.

Results for

Bearings for alternators - Import exportNumber of results

7 ProductsCountries