- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearing guides

Results for

Bearing guides - Import export

AVM AUTOMATION

France

These linear guide bearings are available in cylindrical short housings or prismatic long housings. Guided on ball bushings, bronze or polymer bearings. The housing is in anodized aluminium. To build your own linear guide These linear guide bearings make it possible to create a guide unit adapted to your needs and integrated into your machine You choose the diameter of the guide rods according to load capacity and rigidity, the type of guidance (bronze, polymer, ball bushings), the guide length (long prismatic or short cylindrical bearings) and the rods spacing according to the application. You can integrate any cylinder (type, standard, brand …) by using a cylinder rod coupling. You limit the number of parts by directly using a support of your frame and your end plate. A range of stainless steel guide bearings is also available Guide Type 34X You can also use bearing blocks

Request for a quote

AVM AUTOMATION

France

Table for pneumatic cylinders ISO Ø16 to Ø40 Guided on ball bushings Protected by wipers seals More rigid than a H guide unit These tables maintaining the same quality of guidance and rigidity throughout the stroke. For a offcentered payload in vertical, these tables allow to be more rigid than a guide unit in H. Hydraulic shock absorber on this table A hydraulic shock absorber may be placed in opposition to the pneumatic cylinder to dampen, for example, the descent and/or limit the stroke at the output of the cylinder rod. The retracting stroke can be adjusted by the floating rod coupling. Use in harsh environment For dusty environments, additional nitrile or polyurethane scrapers can be added in front of the ball bushings. An anticorrosion version can be proposed with the rods, the coupling and the screws in stainless steel (the carriage and the plates remain in anodized aluminum). It’s possible to make these tables with plain bearings (bronze or polymer) on request.

Request for a quote

AVM AUTOMATION

France

Table for manual using or outside motorization Guided on ball bushings Guide tables without transmission These tables are used for manual movement or for external drives. The end plates are tapped in the center to optionally receive a hydraulic shock absorber or stroke adjustment. On request, a position clamping is available (option /BP0* on leadscrew tables). Range of linear tables with cylinder or screw transmission These tables exist, in the same dimensions, in different versions – suitable for pneumatic cylinder Type 307 – with trapezoidal screw for electric drive Type 308 – with ball screw for electric drive Type 308 – with trapezoidal screw for manual drive Type 309

Request for a quote

AVM AUTOMATION

France

For pneumatic cylinders ISO Ø8 and Ø10 Guide on bronze bearings or ball bushings The smallest guide unit in the range It’s the smallest unit, suitable for ISO6432 Ø8 and Ø10 pneumatic cylinders, allowing an ISO cylinder to be kept for small guided cylinder applications. It has a long Ushape to remain compact and have a guide length comparable to an Hshape. For environments requiring an anticorrosion version, the steel parts can be supplied in stainless steel (rods, coupling, screws), the body and the front plate are remaining in anodized aluminum (suffix /AC after the reference). Any special stroke is possible, with a maxi stroke of 200 mm.

Request for a quote

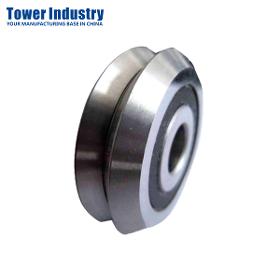

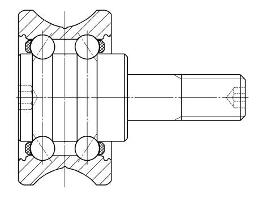

NINGBO TOWER INDUSTRY CO.,LTD

China

bearing,pulley,guide bearing,ball bearing

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

V Groove Guide Bearing, bearing, groove bearing

Request for a quote

DUTCH PERFORMANCE PRODUCTS VOF

Netherlands

In addition to a high temperature range, this product has many more unique properties. The High Temperature Grease does not melt, drip or char. Not even at extreme pressure and extremely high temperatures. The HT-G also protects against corrosion and provides long-term lubrication. This product is ideal for the lubrication of, among other things, guides, valves, shafts, bearings, crown wheels, open gears, transmissions and mainly roller and ball bearings that have to deal with high temperatures. Ultimately, using the High Temperature Grease will result in less machine maintenance and longer life. When HT-G is used, it will change color from pale gold to light brown while acquiring a slightly firmer character at a temperature of about +/- 121 ° C.

Request for a quote

ROLLON GMBH

Germany

Versatile and innovative curved linear guides with radial ball bearing rollers. The curvilinear guides are available in different versions, with constant or variable radius. CURVILINE is ideal for applications such as curved machine housings, door systems in trains or boats, or customized packaging units. Two rail widths: 16mm and 23mm Zinc plated rails and sliders as per ISO 2081 Strokes over 3,000mm Straight and curved paths in one rail Sliders with four rollers, arranged in pairs, maintain the preload over the whole length of the rail Parts as per drawing, customized for each application The Curviline linear guides product family is used for all non-linear motion applications. The linear rails are available in two widths, and made to fit the customer’s design. A single rail can have both curved and straight sections. Main fields of application for Curviline linear guides: Railway Naval Packaging Food & Beverage

Request for a quote

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

ROLLON GMBH

Germany

High load capacity and reduced deflection telescopic rails with caged balls bearings. The telescopic guides have optimal running properties due to inductively hardened raceways. TELESCOPIC RAIL linear slides exhibit little deflection while under very heavy loads, even when fully extended. Telescopic guides come in eight different series (DS, DSE, DSC, DE, DBN, DMS, ASN, DRT) Torsionally rigid intermediate elements with S-shaped, double-T, or squared sections Over-extending, full or partial telescopic strokes are available In the DMS63 Series the supported load can reach 2,000kg per pair. Extremely low deflection and smoothness of movement even in high load, 24/7 applications Some Series can be locked in the closed position Special versions and strokes available upon request The Telescopic Rail product family includes full or partial extraction telescopic rails, and consists of eight (8) different sizes. The deflection resistant central components are available in the S, double T...

Request for a quote

ROLLON GMBH

Germany

Compact Rail is a linear system consisting of steel linear rails with induction hardened raceways and high precision radial ball bearing sliders, also made of hardened steel. Thanks to their self-aligning capabilities, Compact Rail linear guides simplify the project, improve the performance and reduce the overall cost of application. Compact Rail linear guides are easy to install on all types of surfaces, including non-machined ones. Compact Rail linear guides feature a robust steel slider with ball bearings, self-centering heads with wipers, longitudinal seals to protect the internal components and a top sealing strip. The slider body is accurately finished with matte longitudinal edge chamfer and a shining ground flat surface. The slider heads are equipped with special slow release felt pads and are free to rotate with respect to the slider body, so that the felts are always in contact with the raceways to ensure optimal lubrication.

Request for a quote

ROLLON GMBH

Germany

The Telerace family consists of telescopic guides made of steel or profiled metal sheeting, treated with a deep nitriding and black oxidation process or available in stainless steel. The Telerace linear guides are ideal for harsh environments as their large rolling components make them highly resistant to dust and dirt. The Telerace guides are ideal for continuous cycle applications requiring a long life and reduced maintenance. They are therefore suitable for industrial automated applications, even with variable stroke cycles. The materials and the surface treatments used in the construction of the Telerace guides ensure a good rust protection, making them suitable even for outdoor applications or humid environm.

Request for a quote

ROLLON GMBH

Germany

Compact Rail Plus linear guides feature double row ball bearings for higher load capacities and rigid rails with convex raceways and new robust steel sliders with longitudinal protection and floating wipers, Compact Rail Plus has been designed for the most demanding applications in terms of high load capacities, high dynamics and work environment. All while maintaining the self-aligning capabilities that make this product family unique. Sliders are available in four versions: guiding slider (RV); floating slider (RP); extra-floating slider (RU) and rotating slider (RA). Combining two rails with different sliders makes it possible to create self-aligning systems that can compensate misalignment errors on two planes: axial up to 3.5 mm and radial up ±1.3°.

Request for a quote

ROLLON GMBH

Germany

Linear actuators with different guide configurations and drives, available with belt, screw or rack and pinion drives according to different needs in terms of precision and speed. Guides with bearings or ball recirculating systems for different load capacities and critical environments.

Request for a quote

ROLLON GMBH

Germany

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

IGUS® GMBH

Germany

iglidur® flange bearing d1 [mm]: With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. When to use iglidur® flange bearings? When you want a screw flanged bearing When a clip bearing solution is not satisfactory as a sheet metal feedthrough When there is a housing with very rough tolerances When the tight fit of a press-fit bearing is not sufficient as an axial securing When not to use them? When an additional angle compensation is required igubal® flange bearing When a screw connection is not possible iglidur® clip bearing When a large guide length is necessary iglidur® G General features With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered. Installation Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation. Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X The mounting of the iglidur® flange bearing: Simple and safe iglidur® flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

MDM Double flange bearing b1 [mm]: When to use it? When the axial safety of the iglidur® clip bearing is not sufficient When there is a housing with very rough tolerance When high axial forces must be absorbed When not to use it? When an automated assembly is required iglidur® MKM When the iglidur® clip bearings offer adequate tightness iglidur® clip bearing When a large guide length is necessary iglidur® MKM MDM Double flange bearing b1 [mm]: Special features Large flange surfaces Symmetrical flange Easy installation Easy to clip on Undetachable after cataphoretic painting process Special option possible

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

WIB SA

Switzerland

As the leading manufacturer of linear guide system bearings, WIB works collaboratively with customers on the development of common and tailor designs, supplying the best-in-class technical and commercial solution for each unique application. Each parameter, including environmental factors, precision requirements, speed, temperature, load, boundary dimensions are thoroughly evaluated during the design and development phase.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Using IKO CLube Linear Way L for the linear motion rolling guide and IKO Crossed Roller Bearings in the rotation guiding parts, while adopting direct drive method in the drive section, IKO Alignment Stage SA···DE is a compact, lowprofile alignment stage which achieves XYθ motion.Alignment Stage SA···DE achieves highly accurate positioning without backlash by combining a highresolution linear scale and full closed loop control. An ideal positioning mechanism for alignment processing using image processing, such as in semiconductor/liquid crystal manufacturing equipment, or for measuring instruments or testing and inspection equipment requiring clean environments.

Request for a quote

FRANKE GMBH

Germany

The stop screws are screwed into the thread (option) of the guide rails. An attached rubber cap dampens the stop. For rail lengths with initial hole dimensions below L11 min. we deliver the drilling pattern offset by half a drilling jump.

Request for a quote

NORELEM FRANCE

France

Body carbon steel. Balls roller bearing steel. Diverters plastic. Standard guide carriage with recirculating ball guidance precision N not preloaded (Z0). With doublesided end seal. 4row versions with round arch profile. The profile guide rail tracks are arranged at 45° and can accept loads from all directions. High dynamic values v = 5 m/s. Applicable temperature in continuous use max. 80 °C. On request Various precision and preload classes. Drawing reference 1) ground ref. edge

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of normal-load friction, rolling and pivoting bearings Lubrication of spindles and guides at machines Lubrication of moving parts at fine-mechanical devices as well as household appliances Advantages and benefits Lubrication when dark-coloured lubricants cannot be used Saving of maintenance and lubricant costs by reducing downtimes and corrective maintenance Waterproof Clean the lubricating points well for optimal effect. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value below 50,000) and their housings should be filled completely. In as far as available, the bearing and machine manufacturer's instructions should be observed.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Absolute exposed linear encoder for CNC machine tools with Siemens (DRIVE-CLIQ) , Fanuc and Mitsubishi CNC. Due to the magnetic operating principle of the SQ47, the measuring system is extremely insensitive to contamination, e.g. oil, water and dust, while at the same time providing maximum accuracy and resolution. Contactless read head design without ball bearing guide Measuring lengths: 90mm - 3.740mm Accuracy: 3+3ML/1,000 µm(p-p) Max. Resolution: 5nm Max. Response speed: 200m/min Protection class: IP67 without supplied air Interface: Siemens DriveCliQ, Fanuc, Mitsubshi Thermal expansion like steel Easy installation

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Hydrostatic bearings are characterized by practically frictionless movement. The corresponding linear guides are free from stick-slip effects and there is practically no wear on the guides. Gases (mostly air) or liquids (mostly oil) can be used as the carrying medium. Air-bearing guides are ideal, for example, for clean room applications or at high sliding speeds. If oil is used as the carrying medium, higher carrying forces can be achieved with the same size and better damping properties. Various designs are available, which can be customized at any time to meet special requirements in terms of installation space, load capacity, guide length / table diameter, drive type, position measuring system, etc.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of tooth flanks and sliding surfaces of machine elements of all types, for example sliding bearings, slideways, guides, etc. Run-in lubrication of heavily loaded tooth flanks and sliding surfaces Lubrication of jackscrews in the motor vehicle and train technology Cable lubrication Advantages and benefits High effectiveness thanks to graphite share Extremely low friction at highest load Increased operational reliability of moving parts due to run-in-supporting formation of sliding film Minimum consumption due to realisable thin-film lubrication Excellent pressure resistance Waterproof Free of bitumen, solvents, heavy metals and chlorine

Request for a quote

FLUX-GERÄTE GMBH

Germany

The sealless Drum pump F/FP 424 is ideal for transferring various low-viscosity, also aggressive media. It is suitable for media that flow quickly and neither bond, crystallize nor are abrasive. With this pump you can empty drums, IBCs and also basins. Distinct feature, only at FLUX: The specific construction with spiral-shaped guide bearing in the inner tube prevents unwanted deposits in the pump and increases the service life significantly. The pump is available in stainless steel, polypropylene or polyvinylidene fluoride. Benefits: - No seal wear - Optimal emptying of the inner tube - High service life - Low wear of guide bearing and shaft - Long life circle of bearings - Particularly suited for hydrochloric acid and chromic acid - Can be temporarily operated against closed valve (hand nozzle, valves etc.) until the indicated temperature of the materials is reached - Stainless steel version for use in hazardous area

Request for a quote

FERPLAST SNC

Italy

BSL 5045 SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Angular packaging machines with manual or automatic closing of the sealing bar and motorized product unloading belt. They can be combined with a retraction tunnel. FEATURES: - Sealing blade in NI-CR with non-stick coating - Control of the welding time to avoid overheating - Conveyor belt adjustable in height by handwheel - Double magnet for high closing force - Reel holder sliding on ball bearing guides, useful width mm. 550 - Return of the sealing bar controlled by a gas spring (for the 5045 L manual version) - Pneumatic device (compressed air) for closing and opening the sealing bar (for the BSL 5045 LA semi-automatic version) The BSL 5045 LA model is equipped with a maintained action dual control (the two buttons must be held down until the bars are completely closed).

Request for a quoteResults for

Bearing guides - Import exportNumber of results

94 ProductsCountries

Category

- Cylinders, pneumatic (10)

- Internal transport systems (8)

- Rails and sliding frames (8)

- Silicones (6)

- Bearings - ball, needle and roller (5)

- Lubricants for cars (5)

- Tools & Hardware (4)

- Bearings, ball (3)

- Joints, pneumatic (3)

- Lubricants, industrial (3)

- Bridges - construction (2)

- Engines & Parts (2)

- Industrial cutting machine tools (2)

- Measurement - Equipment & Instruments (2)

- Pneumatic systems and tools (2)

- Bearings, roller (1)

- Cleaning and maintenance products, industrial (1)

- Construction Materials (1)

- Expansion joints - ferrous metal (1)

- Goods handling systems, continuous (1)