- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- basic bearings

Results for

Basic bearings - Import export

FRANKE GMBH

Germany

Elastomer sleeves are available on request for Franke LSA slim bearings. They are used for tolerance compensation and for vibration decoupling. The smooth running can be significantly increased by an elastomer sleeve. Elastomer sleeves for the LSA 6/8 also offer additional sealing of the bearing due to the overlapping of the edges. Elastomer sleeves for Franke slim bearings are available from stock. They can be ordered when you buy a slim bearing and are then included in the delivery. For series production, elastomer sleeves are available by the meter for self-cutting. We recommend gluing the ends with cyanoacrylate glue (e.g. Loctite 406). The use of the elastomer sleeve slightly reduces the stiffness and accuracy of the bearing. The basic static load rating of the bearing also decreases slightly. We would be happy to advise you on the design and construction.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs.Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

PROMSTROIKONTRAKT

Russia

Universal deck form PSK-CUP combines the functions of deck form and scaffolding. The deck form PSK-CUP corresponds to the space frame which forms the rigid frame without joints which does not require additional stabilization by diagonal connections in most cases. It is assembled from the tubular members: vertical and horizontal, lower threaded lifting jacks and upper threaded uniforks, connection elements, it may be completed with fixation elements. Vertical elements are the basic bearing components of the framework on vertical plane. There are six basic dimension. They are joined with the help of connection elements according to the principle “tube-in-tube”. In every 500 mm the vertical elements have welded cup connections – “lower cup” produced from the high-quality steel, with the attached mobile cups – “upper cup” produced from ductile casting. They provide support for horizontal elements. The horizontal elements provide the framework rigidity.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

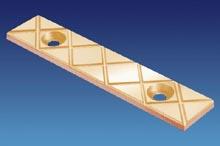

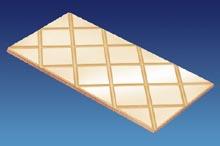

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

Adding some supplementary features to the basic bearing types, FIP INDUSTRIALE can also produce special bearings, suitable for targeted purposes. These are the main types: Negative load bearings Also known as "anti-lifting" or "double-acting" bearings. These devices are also capable of resisting vertical tension loads, commonly denominated "negative". Load measuring bearings They permit in-situ measuring of vertical loads acting on the bearings. Depending on the technology used, measurements can be made next to the bearing or remotely, at any time of the bearing life span. Bearings with dampers These are a combination of one multidirectional or unidirectional bearing with hysteretic and/or viscous dampers. They are also called "flat sliding isolators with dampers". Bearings with shock transmitters Sliding bearings coupled with shock transmitters. In case of sudden movements, for example seismic movements, the shock transmitters prevent the relative movements of the structural eleme

Request for a quoteResults for

Basic bearings - Import exportNumber of results

11 ProductsCountries

Company type