- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- axial centre

Results for

Axial centre - Import export

WESTMARK GMBH

Germany

• coated thread with axial centre • esthetically pleasing, good quality feeling • robust design • satin-shine surface

Request for a quote

TROTEC GMBH

Germany

The axial fan model TTV 7000 is a specially designed solution for industries requiring film and event services. The TTV platform is placed at the centre of the axial fan. The principal aim of the TTV series of fans is to provide highest of performances, delivering economically and achieving high levels of flexibility. The TTV series aims at catering to more applications using lesser tools. The on-site flexibility is enhanced due to the fact that applications can be changed as and when desired on-site to meet the ever demanding industry. Multiple tasks can be addressed by just one fan fitted into the system. The system is also protected from splash water, it can be stacked over to save space and is extremely economic and delivers exceedingly high levels of efficiency.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

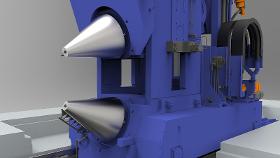

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Axial centre - Import exportNumber of results

4 ProductsCountries

Company type