- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automation machine

Results for

Automation machine - Import export

MAROVT D.O.O.

Slovenia

The advantage of the Marovt company is that forged parts are machined in our own forge. This is why we are able to ensure forged parts with characteristics defined together. The machining of forged parts is mostly automated; therefore, the human factor is decreased and permanently the same technological process can assure all parts to be machined in the same way and being controlled and tested according to the same procedures.The machining of forged parts is carried out on technologically advanced 3 and 4-axe machines. Our machining centres have the possibility of using up to 40 changeable cutting tools. The tool can be up to 300 mm long and up to 10 kg heavy.The machining center spindle can rotate up to 20,000 rpm. Changing the cutting tool at our centers only takes 1.7 s, which greatly shortens the machining time. All our machining centers have a pallet system that eliminates the time of mounting the forging parts into the clamping device.

Request for a quote

STOBA SONDERMASCHINEN GMBH KG

Germany

stoba ECM systems with adapted automation solutions for multishift operation System comprising proven standard modules Integrated process chain of transport, ECM, cleaning, drying and removal Expansion stages based on the production volume Achieving economic cycle times Layout adapted to space Process integration and support from a single source

Request for a quote

IRIS PACK

Poland

New fully automated machines for the production of disposable plastic gloves made of HDPE / LDPE foil

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling is an automated machining process used to manufacture 2D and 3D parts by removing material from raw stock . This process is used in various industries such as aerospace, automotive, and industrial equipment to produce a wide range of parts, including gears, shafts, brackets, and housings .The precision and accuracy of CNC milling make it an ideal process for producing complex and high quality parts .It can produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal...

Request for a quote

THOMSON MACHINERY BV

Netherlands

Dimensions L350*W400*H220(mm) Voltage AC 220V50HZ Air pressure 2-3fkg/cm² Working temperature 5-40ºC Working humidity 20%-90%RH Feeder capacity 2000-5000pcs Efficiency 50-70pcs/min Feeder mode Vibratory feeder Screw Delivery Method Blowing type Applicable screw M2-M6 Working Efficiency 0.8s/screw Weight 15kg

Request for a quote

THOMSON MACHINERY BV

Netherlands

Exciting vibration force and power are well matched, vibration force is large, the weight of the body is light, small volume, low mechanical noise; 2) Stable amplitude; 3) Adjustable& flexible Vibration frequency; 4) Simple structure in linear type ,easy in installation, maintain, and operation; 5) Adopting high quality material parts ,electric parts and operation parts. 6) High performance feeding speed. 7) Various model, can be customized

Request for a quote

THOMSON MACHINERY BV

Netherlands

MODEL KY-2 POWER 0.85KW VOLTAGE 380V/50Hz FILLING CAPACITY 100ML-500ML PRODUCE CAPACITY 1500BPH AIR PREESURE 0.5-0.75MPA WEIGHT 800KGS SIZE 1500*1000*2100MM

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This fully automatic labeling line is suitable for reliably applying self-adhesive labels to various products such as envelopes, catalogues, magazines, etc. The machine is equipped with a completely overhauled rotary feeder from CMC, which we installed as a self-sufficient unit with a new vacuum pump and motor in a stable frame made of aluminum profiles. We then paired them up with a new vacuum table with electric height adjustment and an "Alpha Compact" labeler from BLUHM/WEBER mounted on it. Together with a new machine control system these modules can be assembled into a fully automatic labeling line with which our customer can process products up to 43 cm in length at high speeds (up to 70 m/min). Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

STATEC BINDER GMBH

Austria

The PRINCIPAC is a fully automatic high-performance bagging machine for open-mouth bags and, with up to 2000 bags per hour, it is one of the fastest in the world. The PRINCIPAC is characterized by high performance and flexibility. Both pillow bags and gusset bags with a filling weight of 10 kg to 50 kg can be processed. The bags can be made of woven PP, PE and paper. This fully automatic open-mouth packaging machine is ideally suited for any type of free-flowing bulk material and with additional equipment such as a dustproof filling spout also for powdery products. Depending on customer requirements, the high-performance bagging machine can also be made entirely of stainless steel. Further options enable the PRINCIPAC to be optimally adapted to customer requirements.

Request for a quote

RONIX GMBH

Germany

Ronix segmented granite cutting discs are manufactured by hot press production process with fully automated machines. In comparison to cold press production process, the hot-press cutting wheels can deliver higher efficiency. These circular granite cutting blades have also a longer life cycle compared to others. To provide the users with a great cutting experience, the best possible and highest quality raw materials are used to produce Ronix granite cutters. The unique formulation of materials in the diamond tips of these discs, minimizes friction between the workpiece and the blade which results in a faster and cooler cut

Request for a quote

MICRO-EPSILON

Germany

The thermoMETER TIM 8 combines the advantages of a robust pyrometer with a thermal imaging camera. Due to its extremely compact size, it can also be integrated into machines and production lines. The spotfinder function enables precise temperature measurements with automatic sensor adjustment. In addition, remote focusing of the lens is possible via a motorized focus. This intelligent spotfinder pyrometer is used in automation, machine building and plant monitoring.

Request for a quote

MICRO-EPSILON

Germany

Non-contact eddyNCDT 3300 eddy current displacement sensors are designed for use in factory automation, for machine monitoring, for quality control and quality assurance. More than 80 differentes sensors models are available.

Request for a quote

RONIX GMBH

Germany

Stones and granites are one of the most durable materials in the world. Almost all of the ancient buildings that has remained from various periods in the history, were made of granite and stone. Because granite is an extremely durable and highly resistant material, cutting and shaping plates of granite needs specific tools. However, to do the job, these tools also require cutting disks. This is why we at Ronix produce high-quality and strong granite cutting wheels as accessories. Our Granite Cutting Disks are made of top-quality raw material and with a unique formulation to deliver great performance and be as efficient as possible. Ronix segmented granite cutting disks are manufactured by hot press production process with fully automated machines. In comparison to cold press production process, the hot-press cutting wheels can deliver higher efficiency.

Request for a quote

RONIX GMBH

Germany

Ronix RH-3510 & RH-3511 Granite Cutting Discs are manufactured by cold press production process with fully automated machines. These wheels are produces in a way to ensure faster cuts and longer lifetime of the cutting disc itself. To provide the users with a great granite and marble cutting experience, the highest quality materials are used in the production of these Ronix cutting discs. The unique formulation of materials in the diamond tips of these discs, minimizes friction between the workpiece and the blade which results in a faster and cooler cut. Since granite is a highly durable and resistant material, the process of cutting it causes a lot of friction. This is why many people prefer to add water and other liquids to the cutting process to cool down the disc in order to protect it. For this reason, we at Ronix manufacture our granite and marble cutting discs so be suitable for both wet and dry cutting to suit a wide range of consumers’ needs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

MTA ROBOTICS AG

Switzerland

MRC500 soldering platform for robotic soldering from above is a free-standing machine cell. Our design engineers purposes-built the MRC500 for soldering applications then standardized the design. We purpose-built our own platform so we would not need to compromise functionality based on the limitations of third-party equipment. Standardizing the design offers three primary advantages. It is well-proven, available faster, and costs less than-off custom designs. Although the design is standard, it is highly flexible. We designed the mechanical structure to work with a wide range of process equipment, material handling, and guarding systems. In its basic configuration, the MRC500 is a free-standing, semi-automated machine. At the other extreme, we can outfit it with SMEMA conveyors, collaborative robots, turntables, and many other systems.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IRIS PACK

Poland

New fully automated machine for the production of bags,disposable plastic gloves made of HDPE / LDPE foil. Machine started, tests done. Possibility to check. Station with double unwinding, equipped with clutches for smooth adjustment of HDPE tape tension, double inverters controlling unwinding. The machine uses a central drive that controls all mechanisms responsible for forming production. The feeding of the material is controlled by a stepper motor (servo drive) enabling precise feeding of the HDPE or LDPE tape to the welding position and the final product sorting point. Possibility of changing the welding dies to different sizes of gloves or the production of bags, e.g. for breakfast. Capacity approx. 160 pieces / min Power consumption: 10 Kw Compressed air demand: 8 BAR Weight: 1300 kg

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a wide range of tools for the manual and automated finishing of cast workpieces in foundries. These include cutting discs for angle grinders and stationary machines as well as roughing discs in various degrees of hardness. Resin-bonded tools and diamond grinding discs offer maximum service life and precision for the automated machining of grey and nodular cast iron. Tools for all requirements In addition to cutting and grinding discs, the range also includes mounted points and carbide burrs for straight grinders and industrial robots, which are ideal for hard-to-reach areas. A large proportion of the products belong to the PREMIUM segment, which speaks in favour of the high quality of Tyrolit tools. Advantages of the Tyrolit range: . Variety of shapes and dimensions . Long tool life and cutting ability . Consistently high performance . Above-average comfort

Request for a quote

FÖHRENBACH GMBH

Germany

The versatile control unit for handling, assembly technology, linear robots The unipos 330 is a universal, modular CNC continuous path control for up to 3 axes (interpolating) in connection with a PLC for controlling most reliable applications for machine construction automation technology, machine tools and special applications. Depending on the design, either stepper motors or servomotors are used as axis drives. The integrated panel PC with the LINUX operating system allows convenient programming of your application and the user interface (HMI). Features Interpolating continuous path control for a maximum of 3 servo axes CNC programming using G code 1 to 3 axes / stepper motors or servomotors Processor: 32-bit microcontroller, 400 MHz, without fan 7" touch screen, resolution: 800 x 480 DPI, TFT colour

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

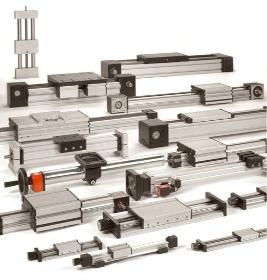

Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

One of the most significant advantages of an automatic piston filling machine is that it reduces labour costs and increases production speed. The machine can handle a high volume of products, which can help to reduce manufacturing costs in the long term. Furthermore, as the machine is fully automated, it minimises the risk of human error, which further increases production efficiency. Model Recommended: NP-VF 12 Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

MINEBEA INTEC GMBH

Germany

OPC UA (Open Platform Communications Unified Architecture) is a standard for communication in the field of industrial automation - more precisely: a machine-to-machine communication protocol for industrial automation. The server enables cross-operating system data exchange between, for example, scales and higher-level systems such as ERP or MES systems. miOPC is suitable, for example, for the Combics, Signum, Midrics and IS platforms. With miOPC, Minebea Intec, as an innovation leader, offers a new solution for the market that takes an important step towards standardisation and customer independence. Your benefits: — Simple connection of existing scales via Ethernet TCP/IP or serial RS232 — Standard OPC UA scale profile according to the OPC Foundation: "OPC UA Compendium Specification for Weighing — Data security through encryption — Simple, intuitive operation

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For removing dust prior to maintenance and repair work, e.g. on magnetic plates, reading heads, audio-visual magnetic tape recording and playback heads, phonograph pick-ups, record turntables or phonograph records For cleaning vacuum sealing surfaces, sealing rings, high-voltage insulators, sample containers etc. For vacuum systems and device groups under clean-room conditions for semiconductor production Cleaning of opto-electronic reading units for bank checks and contactless cleaning of optical devices For maintenance of automated teller machines, quartz clocks or display panels For dedusting precision mechanical parts and assemblies in office machines, copiers, fax machines etc. Advantages and benefits Excellently suited for dedusting, blowing out and blowing off dust and liquids of all kinds Dry, oil-free compressed gas leaves behind no residues Replacement for ultrapure compressed air

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quoteResults for

Automation machine - Import exportNumber of results

158 ProductsCountries

Category

- Construction - Machines & Equipment (10)

- Servomechanisms (9)

- Measurement and control instruments (6)

- Packing and packaging - machinery and equipment (6)

- Storage equipment and systems (6)

- Laser - cutting and welding machines (5)

- Automation - systems and equipment (4)

- Cleaning and maintenance products, household (4)

- Electrical systems and equipment (4)

- Machine tools - metal machining (4)

- Sensors (4)

- Adjustment - machine tools (3)

- Brick-making - machinery and equipment (3)

- Industrial cutting machine tools (3)

- Paper - Printing - Machines & Equipment (3)

- Tools, pneumatic (3)

- Bags, plastic (2)

- Cement-making - machinery and equipment (2)

- Cutting - steels and metals (2)

- Engines & Parts (2)