- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automating the production process

Results for

Automating the production process - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Business sectors : environment and renewable energy peripheral equipment for the transport of lightweight consumer goods (≤ 10 kg) by autonomous drones via aerial highways peripheral technological equipment for self-driving land vehicles development and integration of specialist digital solutions for automated production processes

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond DSV Sideshooter provides reliable detection of foreign objects in upright tall packaging. The compact, hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond D side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

BME BAUMASCHINEN ERSATZTEILE INH. DIPL.-ING.(FH) MATHIAS SCHMIDT

Germany

The idlers we offer are manufactured according to the latest automated design and production processes. The idlers from our range have the required quality and are particularly suitable for high continuous loads. For this purpose, special hardening techniques and heat treatments are used in production, which efficiently increase the wear resistance of the running surfaces. This was taken into account because wear resistance plays an essential role in the industrial sector due to the stress on the intervening components. When manufacturing the idlers, we rely exclusively on highquality seals and contemporary bearing designs to ensure high durability and reliability. Production is carried out according to current industry standards and meets even the highest requirements. The finished sorocket offers high wear resistance of the running surfaces even under extreme loads.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond S side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

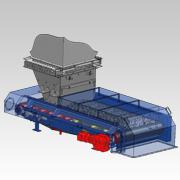

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Whether for large or small conveyed quantities, no matter the application, from luxury food processing to the steel industry, AViTEQ Belt weigh feeders assure high weighing precision for reliable, uninterrupted operations. In automated production processes requiring constant weighing and metering, Weiteq Belt Weigh Feeders are the first choice. Advantages and benefits For feeding a wide range of bulk materials from free flowing to bridging High long- and short-term accuracy Robust construction allows ease of installation and belt replacement Customized feeder sizes, belt type and feed hopper based on bulk material handling experience Special solutions for high-accuracy feeding and heavy duty operating condition Can be used with different types of feeding equipment and directly at the silo outlet Application Components feeding for blending Feeding of additives Batch charging Wagon and truck loadingFeeding and control systems for mills, crushers and mixers Technical data WBL-L WBF-M W

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

EC PLAZA

South Korea

DH Lighting has been leading Automotive Lighting Industry of the world under the spirit of Trust, Technology and Future since 1994. Automotive Halogen Bulbs are the main stay of DH Lighting which is well-known as “EXCELITE” brand through the export more than 50 countries as well as OEM supply to Korean and overseas car makers. We have the largest production capacity of the bulbs in Asia which covers the full ranges with the highest OEM quality by its own automated production lines. Each manufacturing process in the factories is under the strict control with ISO/TS 16949, IATF16949, ISO 9001 and OHSAS18001. All standard bulbs have been acquired the world top class quality approvals such as E1 and SAE-DOT.

Request for a quote

AIS HENSCH AUTOMATION-INDUSTRY- SOLUTIONS INH. IGOR HENSCH

Germany

The industrial CPUs from AIS Hensch Automation-Industry-Solution represent a first-class solution for controlling automated production processes in various industrial sectors. These CPUs are characterized by their technological excellence, reliability and versatility, making them an indispensable component for optimizing manufacturing processes. Thanks to their powerful processing, our industrial CPUs offer precise control that can be seamlessly integrated into a wide variety of production environments. From the oil and gas industry to mechanical engineering, these CPUs flexibly adapt to the specific requirements of different industries. The robustness and longevity of our industrial CPUs ensure reliable performance even under demanding conditions.

Request for a quote

GFE-SOLUTIONS EUROPE SP. Z O.O.

Poland

CNC machines programming – is a method used for generation of software instructions for managing machines, units, mechanisms. As a result, the correctly adjusted and algorithmized equipment allows to automate the production process and to ensure higher flexibility of the company for industrial requirements and tasks. GFE-Solutions’ specialists provide algorithmization services for the operation of CNC machines of any type using profile software remotely for industrial enterprises throughout Europe. During operation and preparation of new algorithms, GFE-Solutions’ specialists are guided by advanced technical documentation of the industrial company, as well as reasonable quality standards in the customer’s industry that allows finding an optimal economic, technical and operational solution. Within the framework of cooperation, we can send both an outstaffed employee and a complete team of software engineers with conduct visit to the customer’s for expert evaluation, ensuring the comple

Request for a quote

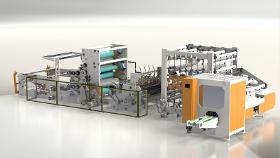

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Dual Toilet Paper and Kitchen Towel Production Line is an advanced technology that offers a high-capacity and efficient production system that occupies an important place in the modern paper production sector. This production line stands out with its ability to produce both toilet paper and kitchen towels at the same time, thus increasing production flexibility and capacity. Equipped with advanced automation features, this line makes production processes faster and more efficient. Automatic (Dual) Toilet Paper and Kitchen Towel Production Line is an automatic production system that can produce toilet paper and kitchen towels at the same time. Thanks to its dual-functional structure, it can produce two different products on the same line and without interruption, which increases both the speed and efficiency of the production process. Dual embossing unit: Ability to produce both toilet paper and kitchen towels.

Request for a quote

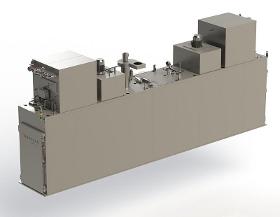

REP INTERNATIONAL

France

Horizontal range H49, H59, H610 The range is designed for easy implementation of automated production processes, namely injection moulding of more or less sophisticated technical parts. Clamping force available from 1,950 kN to 4,000 kN. Shown above press types H49, H59 and H610 (with and without brush).

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT: -Lasagne with respective layers of pasta, bolognese, béchamel and cheese on top. -Two product sizes. MACHINE CHARACTERISTICS: -Three distinct zones connected by conveyor belts: oCutting area for the pasta sheet, placed by the operators in the moulds. oDosing area with five multi-purpose dosing machines, alternately positioned to apply the different layers of the lasagne. Volumetric dosing, equipped with servomotor for a homogeneous dosage. o Spun cheese dosing area. -From the control panel and by means of a touch screen we configure the speeds and accelerations of each belt to comply with the desired production. ADVANTAGES -Automated production for high volume processing. -All the processes are completed in a reduced space. -The entire line is easily disassembled for easy and effective cleaning, and its components are suitable for cleaning with pressurised water.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: -Production line consisting of three stations: oInjector with three rows of nozzles to inject 27 croissants simultaneously, and with three needles per nozzle so that the product is well distributed. oGelatine station that impregnates the croissants with gelatine. oTopping unit with ribbon for the chocolate chips to fall onto the product and get stuck in the gelatine layer. -Injection quantity and injection speed are set on the screen, allowing a more precise adjustment. -Between the injection belt and the gelatine belt, which is made up of cords, there is a transfer belt so that the croissants fall correctly in position and without turning, and are stacked for the gelatine shower. ADVANTAGES -Automated production for high volume production. -Three processes are completed in a reduced space.

Request for a quote

BERNSTEIN AG

Germany

The CC-4000 / CC-4000 SL are modular aluminium control enclosure systems. With their outstanding technical features, the enclosures simply and efficiently encapsulate industrial controllers and operator control panels for centralised and decentralised automation in production processes. — Customised solutions to your specifications — Simple and modern industrial design — Freely selectable width and height (max. 800 x 800 mm) — Depths from 52 mm up to max. 646 mm — High-quality extruded aluminium sections (naturally anodised) — Coloured areas that emphasize the design — Optimum heat dissipation due to aluminium sections — Integrated handle elements with vertical section — Protection class IP65 — Front panels internally-mounted or externally-mounted — Internal grooves for fixing components — Product features SL (in addition to CC-4000) - Two enclosure depths (55 und 99 mm) - Slimline design - For encapsulating flat IPCs

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The semi-automatic labeling machine TNC-R was developed for the all-round labeling of tubes. Small batches can be labeled quickly and precisely with the labeller. The tubes are placed manually in the labeling system. As soon as the 2-hand operation is activated, the automated labeling process starts. The product is rotated and shifted, then the wrap-around label is applied exactly to the product. A printing unit can be integrated for individual labeling of the tubes. You can easily print the labels yourself inline. The integration of a printing unit is suitable, for example, for laboratory tubes or sample vessels that have to be provided with individual data.

Request for a quote

NUOVA SAIMPA

Italy

We offer assembly services, both automated and manual, within our production process. Our highly specialized team performs precision assembly operations, accurately combines components, and applies manual finishes to ensure the highest quality of our products.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOREY

France

Miller Weldmaster is excited to present our new line of multisealing automated solutions, the Moduline system. Our new Moduline system is designed for the customer looking to increase business profits by automating their production process. Miller Weldmaster designs machines specifically to meet your automation needs while keeping your production and payback concerns in mind. Our years of industry knowledge enables us perfectly pair your application with the properly tailored Miller Weldmaster Automated machine. The Moduline System with its unique design enables you to select multiple automation options regardless of your production demands. FEATURES, FUNCTIONS, & BENEFITS Modular welding gantries for product versatility Modular unwinds with load cells for fabric tension Modular catwalk for simple seam inspections Modular upper and lower welding heads for versatility and accessibility Modular cutting heads for near final productivity

Request for a quote

DOREY

France

Miller Weldmaster is excited to present our new line of multisealing automated solutions, the Moduline system. Our new Moduline system is designed for the customer looking to increase business profits by automating their production process. Miller Weldmaster designs machines specifically to meet your automation needs while keeping your production and payback concerns in mind. Our years of industry knowledge enables us perfectly pair your application with the properly tailored Miller Weldmaster Automated machine. The Moduline System with its unique design enables you to select multiple automation options regardless of your production demands. FEATURES, FUNCTIONS, & BENEFITS Modular welding gantries for product versatility Modular unwinds with load cells for fabric tension Modular catwalk for simple seam inspections Modular upper and lower welding heads for versatility and accessibility

Request for a quote

DOREY

France

The M 100 is a completely automated production process. From overlaps and hems to grommets and keder, the M 100 will do all welding in one pass through the machine. The M 100 is also able to cut your panels to specified lengths. The M 100 will greatly increase production while decreasing labor costs. FEATURES, FUNCTIONS, & BENEFITS The machine includes Two or more unwinders for PVC covers Two unwinders for reinforced tape for Keder Two unwinders for rope Five hot air welding heads (or more) One cutting system to cut the cover at the desired length

Request for a quote

ENBI PLASTICS & SILICONES BV

Netherlands

The differentiating properties of Liquid Silicon Rubber (LSR) make LSR more widely and easily applicable than conventional silicones with high consistency and thermoplastic elastomers. Since its introduction in the 70’s, Liquid Silicon Rubber has grown into a material with a great variation of types and properties. In addition to the original use in niche applications, Enbi Plastics now uses the material in a wide range of industrial applications. Extensive developments in the making of new compounds, injection systems in combination with mold construction, and automating and guarding both production process and product quality, make LSR an appealing option for medical and food industries, household appliances, automotive, industrial and agricultural sectors. In this article, Enbi Plastics introduces to you the many possible uses of LSR per sector. Would you like to know more about the possibilities of LSR for your organization? Feel free to contact one of our experts.

Request for a quote

TPK VARNA, LLC

Russia

Noodles are prepared from the basic ingredients; wheat flour, oat flour, rye flour, barley flour, water, and salt. All nutritional and beneficial properties of grains remain unchanged. Due to the porous texture, noodles soak up the flavors of a broth. It cooks quickly, which significantly saves time. Modern equipment, fully automated production process, compliance with HACCP standards and principles, product quality control at all stages - from the selection of raw materials to packaging and transportation.

Request for a quote

TPK VARNA, LLC

Russia

Pasta is an innovative product. It is made according to a unique recipe from four types of grains Durum Wheat, Oats, Barley and Rye. It contains 7% fiber (twice as much as regular group A pasta). Thanks to the slow-releasing carbohydrates, pasta helps weight loss. The increased volume of macro- and micronutrients helps to improve your energy level. Modern equipment, fully automated production process, compliance with HACCP standards and principles, product quality control at all stages - from the selection of raw materials to packaging and transportation.

Request for a quote

TPK VARNA, LLC

Russia

Noodles are prepared from the basic ingredients; buckwheat flour, wheat flour, water, and salt. All nutritional and beneficial properties of grains remain unchanged. Due to the porous texture, noodles soak up the flavors of a broth. It cooks quickly, which significantly saves time. Modern equipment, fully automated production process, compliance with HACCP standards and principles, product quality control at all stages - from the selection of raw materials to packaging and transportation.

Request for a quote

TPK VARNA, LLC

Russia

Noodles are prepared from three basic ingredients; wheat flour, water, and salt. All nutritional and beneficial properties of grains remain unchanged. Due to the porous texture, noodles soak up the flavors of a broth. It cooks quickly, which significantly saves time. Modern equipment, fully automated production process, compliance with HACCP standards and principles, product quality control at all stages - from the selection of raw materials to packaging and transportation.

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Production starlim//sterner produces single and two component parts made of silicone using fully automated injection molding processes. Production takes place on our sites in Austria (Marchtrenk and Weisskirchen) and in Canada (London/Ontario). In Austria we run more than 200 injection molding, compound and 2K machines and in Canada more than 35. We deploy ENGEL brand machines with a clamping force range of 40 to 300 metric tons. The machines run in shifts: 365 days/year, 24 h. Micro-injection molding is a separate production unit. To meet special requirements of cleanliness/purity and hygiene starlim//sterner has a clean room meeting the following standards: ISO 14644-1 class 7 & 8 and GMP class C and D. Further processing of your products is possible. Several processing automats assemble, punch or slit the products according to customer's requirements. The starlim//sterner production environment represents the state of the art and is certified to meet industry standards. Using s

Request for a quote

SIMPAC EUROPE GMBH

Germany

C-frame presses are flexible solutions for manual work as well as for automated production processes. The CS is the all-rounder among the C-frame presses, while the ECS is ideal for punching and cutting operations with a higher degree of automation. Overview: ● Press capacity: 350-3,000 kN ● Part size: small ● Slide kincematics: crank ● Application: cutting, stamping, bending, embossing Description and benefits: ● Compact design, no foundation work required, good accessibility for maintenance ● Solid, low-stress annealed press body in monobloc design with minimal frame deflection ● Durable, wear-resistant and very quiet hydraulic clutch ● Casting slide with vibration dampening properties (ECS series) ● 4-fold slide guiding for a high tilting rigidity ● Hydraulic overload protection ● Production time as of 12 weeks

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Wireless seonsoring systems from AMF: flexible, compact and economical. They enable fully automated production processes for clamping technology as well as for modern handling and storage systems. The system consists of sensors and transmitter units that are interlinked both with the gateway and recipient, which communicates wirelessly with the machine control by means of Bluetooth Low Energy.

Request for a quote

LEONI DRAHT GMBH

Germany

Contured fabric tapes, braided into a tube and then flat-rolled. Made from Cu-ETP1 and Cu-OF1, LEONI Histral® alloys upon request, in bare, tin-plated, nickel-plated or silver-plated, hard or soft annealed. Single-wire diameter ranging from Ø 0.05 mm to Ø 0.40 mm. Cross-section ranging from 25 mm² to 120 mm². Our flat-rolled fabric tapes are characterised by straight rectangular edges with a very high degree of dimensional accuracy and very close tolerances. There is an adjustable degree of compaction, with cross-section remaining unchanged, as well as an easy combination of different cross-sections laid on top of each other (modular system). Contured, braided copper tapes have an improved weldability in automated production processes for manufacturing of earthing straps, connectors or electrotechnical components.

Request for a quoteResults for

Automating the production process - Import exportNumber of results

67 ProductsCountries

Company type

Category

- Automation - systems and equipment (22)

- Food - import-export (4)

- Plastics - machines and material for industry (3)

- Textiles - Machines & Equipment (3)

- Electrical & Electronic Components (2)

- Food Processing (2)

- Metal detectors (2)

- Robotics (2)

- Assembly robots (1)

- Bags, plastic (1)

- Casting, steel (1)

- Components and parts for large household appliances (1)

- Computer engineering (1)

- Construction machinery (1)

- Control panels - electric (1)

- Conveyor belts (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Cutting - machine tools (1)

- Electric and electronic components - machines for manufacturing (1)

- Food industry - machinery and equipment (1)