- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic press

Results for

Automatic press - Import export

ANDRITZ KAISER GMBH

Germany

from 630kN upt to 25.000 kN

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner powder press and indexable insert automations of the "RPA 3-SC series" automatically remove pressed blanks from a powder press and deposit them quickly and gently in a definable sample. In the "RPA 3-SC1", the transfer of the individual sintering plates and the loading of the blanks is carried out by a SCARA 4-axis robot. The empty sintering plates are placed manually into a sintering plate magazine, removed with a sintering plate gripper if necessary, and fed to the loading position. The robot then moves to a gripper station, deposits the sintering plate gripper, picks up a part gripper, and starts loading the sintering plate. In the "RPA 3-SC2", sintering plates are placed manually on a double conveyor belt. One sintering plate at a time is automatically transported to the loading position via the conveyor belt. The robot immediately starts to load the blanks. Loaded sintering plates are ejected from the loading position and manually removed from the conveyor belt.

Request for a quote

INOVA TECHNOLOGY GMBH DISTRIBUTION OF MEDICAL TECHNOLOGY

Germany

The DIXI 60 S with its low overall height of 2.17 m and a pressing force of 60 t makes the press the ideal partner for all volume-reducing processes. The DIXI 60 S achieves bale weights of up to 500 kg. No pressing of the bales is necessary in the disposal chain. This makes the pressed bales particularly interesting for the marketing of recyclable materials. The pressing of film and cardboard or other pressable materials make these machines an economical and reliable partner in the disposal chain. The DIXI 60 S model series is ideal for pressing film and cardboard. The conversion from cardboard to foil is carried out by the microprocessor control with a clear LCD display. Optional: - Connection for dust extraction

Request for a quote

INOVA TECHNOLOGY GMBH DISTRIBUTION OF MEDICAL TECHNOLOGY

Germany

The DIXI 4 S is a proven, inexpensive, hydraulic compact press. The entire technology, including cylinders and roller hinges, is located in the housing. Here you get a space-saving solution by filling the press chamber from above. The good visual impression also allows it to be used in areas with public traffic. The DIXI 4 S has a footprint of only 0.7 m2 and can be set up in relatively narrow niches.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

-150 ton -Table: 700x600 mm -Distance between tables max=600 mm min=200 mm -Maximum working pressure:254 bars (Adjustable) -Cylinder stroke: 400 mm -PLC: Siemens 7''

Request for a quote

BORNEMANN GMBH

Germany

Automatically switching stamping presses are automatically advanced with an embossing stroke. Automatically switching are five points as a rule, the other points are switched manually.

Request for a quote

SITEMA GMBH & CO KG

Germany

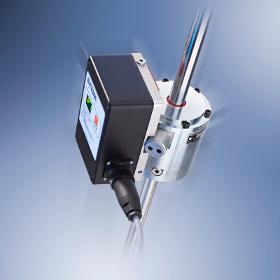

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

SITEMA GMBH & CO KG

Germany

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

SITEMA GMBH & CO KG

Germany

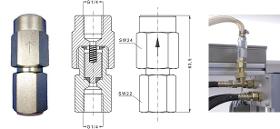

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quote

SITEMA GMBH & CO KG

Germany

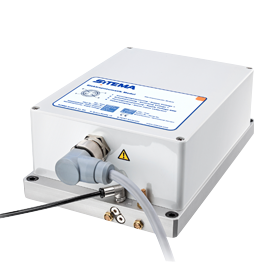

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

it is applicable for round, square & flat bottle it is used in many industries, such as cosmetic, food and pharmaceutical. The caps are round with diameter 12mm-120mm 1. Suit to various bottles and round caps. 2. No need to change parts, easy operation and adjust, low maintenance. 1. Linear structure which is flexible to run different size bottles without change parts. 2. Cap feeding system will be made according to cap sample( by vibrating bowl or cap elevator). Designed with auto cap-feeding, the top belt does online continuous cap pressing, meeting various high-speed cap pressing production requirement. 3. PLC control system and touch screen is available for your option. 4. Mainly made of SUS304 including frame & body, continuous working & highly automation ensuring highly efficiency.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. To provide as large a range of mechanical compatibility as possible, the pins/holes are available in different diameters. Attachments are available which clamp onto the press sensors to enable easy mounting of displacement sensors according to the circumstances of use. FEATURES: — Measuring ranges from 0 … 100 N up to 0 … 25 kN — Small, compact design — Pin/hole diameter from 8 mm to 16 mm — Different diameter for pin and hole can be combined — Mechanical overload protection for all measurement ranges

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The AF filter presses from AQUACHEM are a further development of conventional chamber filter presses, which have been tried and tested in the industry for over a century. However, due to the degree of automation required and the increase in efficiency necessary nowadays, the technology we have had up until now is often no longer up to date. The design of the AF filter presses is based on the optimum interplay of the ?? individual assemblies of the filter press to ensure reliable, efficient and permanent operation without personnel being present. The automated flexibility of the product enables autonomous adjustment to changing conditions, such as concentration or even specific filter properties. We guarantee these properties and also availability. This is only possible because AQUACHEM and the AF-series possess the knowledge, an intelligent control system and the technology for maximum flexibility. Yes, this is a product with unique selling points – test it out yourself.

Request for a quote

AAAGILER GMBH

Germany

Typical fields of application for our vibration damping mats include: - Heavy machine tools - Injection molding machines - Hydraulic systems / hydraulic presses - Punching machines / punch presses / automatic punch presses - coining presses - Die hammers - transformers - generators - Transport carts / truck trailers - Sensitive measuring, electronic and testing equipment, e.g. precision balances and microscopes - Vibration isolation of machine foundations - Vibration and noise damping of rails installed in the track system (high-speed trains, subways, streetcars)

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Pressing bearings Manually assemble anti-knock on hand lever press Automatically assemble and test retaining ring

Request for a quote

BÜRKLE GMBH

Germany

Peleus ball, simple pipetting aid. Evacuation takes place via an automatic valve. By pressing the valves, the liquid is drawn up, dispensed or purged. The removable automatic valve also enables effective cleaning of the inside.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DEKORTECH GMBH

Germany

Manual clam shell type heat press for textile transfers. ✔ Singe platen ✔ Even temperature and pressure ✔ Opens automatically ✔ Up to 50 x 60cm base plate ✔ Magnetic closure ✔ Pull out base plate This quality heat press is great for small businesses. With a long lever it is easy to close this clam shell type heat press. Once closed, a magnet holds the press shut and automatically opens once the set dwell time is reached. The pull-out base makes it even easy to place the textile and transfer. Furthermore, a small gap underneath the base plate allows you to thread the t-shirt onto the platen. Using a small display, you can adjust temperature and a rotary know allows to set the pressure. Last, a special coating on the heated element avoids stains. With a range of different base platens, this press can be used for t-shirts, hoodies, bags, sleeves, legs, bags, neck tags and a lot more.

Request for a quote

DEKORTECH GMBH

Germany

Electric double heat press for textile transfers. ✔ Double platen ✔ Even temperature and pressure ✔ Opens and closes automatically ✔ Up to 40x50cm base plate ✔ No compressor ✔ Laser guides This fully electric double heat press is designed for medium size productions without compressed air. Due to its electric closing mechanism, it is easy to operate without exhausting your arm. And while one side is pressing, you have time to prepare the other for the next cycle. Furthermore, a small gap underneath the base plate allows you to thread the t-shirt onto the platen. Using a small display, you can adjust temperature and dwell time to your likings. In automatic mode, the machine will automatically close and open the press as well as move it from one platen to the other based on set timings. With a range of different base platens, this press can be used for t-shirts, hoodies, bags, sleeves, legs, bags, neck tags and a lot more.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The ROPP capper is the automatic capping machine which is designed to tighten pilfer proof cap for wine bottles, olive oil bottles, drinks bottles etc. It is suitable for φ12-55mm bottle caps (Equipment can be customized according to lid diameter). The automatic operation helps you save labor and reduce production error. The capping machine is a suitable equipment for roll-press-sealing the aluminum caps for the plastic bottle, pet bottle, as well as glass bottle. It processes the screw-press capping for the bottle under the rolling press from hobs, automatically feeding bottle, caps, removing the reverse caps. The capped bottle favors the characteristics like the stable capping effect, convenient uncapping, so that it function as conterfeit and anti-theft.

Request for a quote

BOSPORAS

Turkey

ADS7 series 7-roller straightener servo feeder models work between 300 and 1600 mm of width and 0,5 and 4 mm of thickness. All of our 7-roller straightener servo machines utilize the piloting system and pinch rollers work synchronized with the straightener rollers. Bosporas produces 7-roller Model with static body and in accordance with CE Regulations. Our straightener servo feeders enable high performance automatic feeding to the presses. Servo feeder and straightener are merged and used in the same group. The practice of our models’ feeding system is easy to set up and to control. The angle between the feeder and the coil is 90° parallel. It has the feature of 50 mm of movement capability to the left or right from the feeder’s center. Feeds the sheet metal in an automated cycle, pre-programmed speed and high delicacy.

Request for a quote

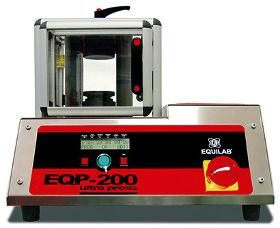

EQUILAB

Spain

The EQP-200 Pellet Press has been especially designed to obtain high quality pellets/tablets for XRF. This press can exert a pressure of up to 40 tons. Of durable and robust design, it is very easy to manage, efficient, and offers 5 working programs with single and double pressing cycles. An exceptional instrument. Keeping all the features of its predecessor (EQP-100), the EQP-200 also offers the possibility of making pellets of different diameters, just by changing the pressing tool. This device facilitates also the cleaning and maintenance tasks. Its versatility enables the unit to work also with different shapes of press tools, such as square, rectangular, etc.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

NEW SWAN

India

New Swan and Gunma Seiko (Japan) has entered into Technical Assistance Agreement for manufacturing of Cold Forged Parts of Aluminium and steel. Gunma Seiko is pioneer in manufacturing of Cold forged parts since decades. With joint aim of New Swan and Gunma Seiko (Japan)to cater Automotive sector, has entered into the ‘TAA’ to serve the automotive sector with Quality and Competitiveness. The plant is ready for production and machinery available for cold forging is Knuckle joint presses, Semi automatic bonding line, Annealing facility, Shot blast machines etc.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Lifting external vacuum packaging machine is vacuum or nitrogen-filled sealing packaging for electronic components, hardware, meat, dry goods, cloth wool products, whole grains, vegetables and fruits, pharmaceuticals, plastic raw materials, food, chemical raw materials, etc. It can achieve anti-oxidation, anti-corrosion, anti-mildew, moisture-proof and other fresh-keeping and quality-preserving effects. Lifting external vacuum packaging machine adopts no vacuum chamber, and the air nozzle directly vacuums or fills the packaging bag with nitrogen. The size of the packaging is limited, and it occupies a small space.This machine adopts long air nozzle design, and the air nozzle length can be adjusted freely from 0--200MM. In addition to the automatic lift transmission design, just press the lift switch. Automatically raise or lower to the appropriate vacuum position, so that the pumping and inflation speed is fast, the work efficiency is high, and the operation is simple and convenient.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Tray erector machine automatic to pick up cardboard, pressing, folding, and forming it into the tray, suitable for corrugated paper, kraft paper, and other cardboard. 2. PLC program control system, the human-machine interface. 3. The transmission and friction parts are strictly following the standard implementation, with less wear and tear in the later stage, and reducing the replacement of accessories. 4.Choice of hotmelt adhesive or lock form tray styles. 5. Adjustment buttons, with fine-scale, easy adjustment to change to another size box,or change the mold. 6. Box storage slot,850mm height, 40kg load capacity, one discharge lasting operation, improve efficiency. 7. Forming mechanism, only three stations are needed to form the box. 8.Equipped with four universal wheels, easy to move after unlocking, convenient for production layout.

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time - Easy to use - Modular add-on components - Powered by low operating voltage Features The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time! - No dust! - No noise! - Powered by low operating voltage! Features: The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time! - No dust! - No noise! - Powered by low operating voltage! Features The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quoteResults for

Automatic press - Import exportNumber of results

44 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (3)

- Turning - steels and metals (3)

- Brick-making - machinery and equipment (2)

- Drainage systems and equipment (2)

- Laboratory equipment and instruments (2)

- Metal industrial presses (2)

- Press - advertising management (2)

- Silk-screen printing (2)

- Stamping - machine tools (2)

- Air conditioning, aeration and ventilation equipment (1)

- Anti-vibration supports (1)

- Assemblies, hydraulic (1)

- Binding - machinery and equipment (1)

- Bottling and filling - machinery and equipment (1)

- Cutting - machine tools (1)

- De-humidifying equipment (1)

- Filtering equipment and supplies (1)

- Food Industry - Machines & Equipment (1)

- Laser - cutting and welding machines (1)

- Mechanical engineering - custom work (1)