- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic packaging machine

Results for

Automatic packaging machine - Import export

FERPLAST SNC

Italy

PRATIKA 55 SMART: AUTOMATIC THERMORETRAIBLE PACKAGING MACHINE WITH INCORPORATED TUNNEL The new model of automatic shrink-wrapping machine Pratika 55 Smart comes from a careful attention to the needs, with the aim of offering a technologically advanced but flexible and extremely compact product. The included tunnel, revolutionary in the world of automatic machines, responds to the needs of space, but above all to reduce the labor costs to a minimum, thanks to the patented "come back" option to a single operator. Enhanced by a strong mechanical and electronic technological content, the new Pratika 55 Smart represents a perfect synthesis of reliability, versatility and safety, which once again evolves the way to conceive the compact automatic operation shrinkwrappers.

Request for a quote

BELGOMILK IA SA

Greece

The cup falls Feeding station Aluminum placing (preset cap) Waterproofing Dating Carrier’s exit Automatic date placement The cup filling machine has three photocells A photocell to check the filling whether there is any cup or not. Thanks to this photocell system, the machine will not lose the product. If there are no cups, then the machine will not proceed with filling. The photocell control for the aluminum lids, whether there is cup or not, thanks to this system if there is no cup then the machine will not waste the aluminum lids. The photocell control for sealing, thanks to this system it checks whether there are aluminum lids on the cups or not, if there are no lids on the cups then the machine will not reach the sealing unit and the machine stops.. Additional options are possible in the yogurt filling sealing machine Flow filter unit-ΗΕΡΑ Second filling station for filling multiple products Adjustment of placement between cap and cap

Request for a quote

FERPLAST SNC

Italy

The PANDYNO FPPD vertical inserters allow to an operator to fill and seal the packs avoiding the use of preformed bags. The operator must in fact insert the product to be packaged in the magazine tube, on which a few meters of tubular film have been previously loaded. The product goes down into the tubular film up to the support surface. The operator manually closes the sealing bar by applying a slight pressure on the bar. The welding machine in a single operation carries out the welding of the package, the cutting of the film and the welding of the bottom of the next envelope. This operation takes place using an electromagnetic blocking device. By equipping the bagging machine with several loaders, it is possible to increase the productivity of the machine. To avoid waiting times it is also possible to pre-load different magazine tubes so that they can be quickly replaced once the film is finished. The standard model can be placed on a bench and comes with a charger of your choice.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Our fully automatic flowpack machines are suitable either for high-speed applications or airtight packaging requirements, depending on the version selected. The machines feature either rotating or box motion transversal sealing units, with selection of a longitudinal seam either above or below. Each machine can be combined with a wide range of feed systems, such as finger conveyor chains or infeed belts. With our ability to handle everything from PP or aluminium laminated films through to Tyvek® – anything is possible. PE-coated paper can also be used for flowpack production. Our flowpack machines are also available as hygienically designed versions.

Request for a quote

STATEC BINDER GMBH

Austria

The CERTOPAC, a fully automatic high-performance bagging machine, packs any type of free-flowing bulk material in pillow bags and gusset bags with a filling weight between 5 kg and 80 kg. Thanks to its high speed, this open-mouth bagging machine can fill up to 1500 bags per hour. Because of the high flexibility of the packaging machine, bags made of woven PP, PE and paper can be processed. Furthermore, the CERTOPAC stands out due to its easy accessibility and high reliability. This high-performance packaging machine is also available as CERTOPAC-S and CERTOPAC-L in addition to the “standard version”. The differences between the variants are the bag magazines (rotating bag magazine or push magazine), the different filling weights and sizes of the bags. Furthermore, the CERTOPAC can also be completely made of stainless steel and equipped for powdery products.

Request for a quote

STATEC BINDER GMBH

Austria

The PRINCIPAC is a fully automatic high-performance bagging machine for open-mouth bags and, with up to 2000 bags per hour, it is one of the fastest in the world. The PRINCIPAC is characterized by high performance and flexibility. Both pillow bags and gusset bags with a filling weight of 10 kg to 50 kg can be processed. The bags can be made of woven PP, PE and paper. This fully automatic open-mouth packaging machine is ideally suited for any type of free-flowing bulk material and with additional equipment such as a dustproof filling spout also for powdery products. Depending on customer requirements, the high-performance bagging machine can also be made entirely of stainless steel. Further options enable the PRINCIPAC to be optimally adapted to customer requirements.

Request for a quote

STATEC BINDER GMBH

Austria

The SYSTEM-F, a fully automatic vertical form-fill-seal packaging machine, produces pillow bags and gusset bags with or without carrying handle and a filling weight between 5 kg and 50 kg from flat film. The System-F is particularly ideal for packaging powdery and moderately free-flowing products. Thanks to an adjustable format set, different package sizes can be produced. The format and/or production can be changed by one person in just a few minutes. This is made possible by a rotating magazine, which is installed directly on the machine and holds several format sets of different sizes ready at all times. The vertical FFS packaging machine impresses with its compact design and low space requirement. Further options allow this bagging machine to be adapted to a wide range of requirements.

Request for a quote

STATEC BINDER GMBH

Austria

The SYSTEM-T fully automatic Form-Fill-Seal (FFS) packaging machine combines high quality packaging from a PE tube with high production capacity and is therefore ideal to be used in a wide range of industries including petrochemicals, fertilizers, animal feed, food,... Due to the high flexibility of the FFS packaging machine it can be adapted to different customer requirements. For example, pillow bags and gusset bags can be produced with or without carrying handle and a filling weight between 5kg and 50kg. Additional perforation of the bags is also possible. The SYSTEM-T stands out due to its modern design and a very sturdy and compact construction. Accessibility, generous clearance, long maintenance intervals and low maintenance costs were of major importance in the development of this machine. For example, the large doors offer easy access to all areas and important parts and cable connections are protected from corrosive and aggressive dust by stainless steel housings.

Request for a quote

STATEC BINDER GMBH

Austria

The ACROPAC is a fully automatic bagging machine with a production capacity of up to 600 bags per hour. Hence, this open-mouth bagging machine is ideal for those who want to change from manual/semi-automatic packaging to fully automatic packaging and/or require low capacity. Whether plastic pellets, animal feed, fertilizer or food, the ACROPAC is ideal for packaging free-flowing bulk materials. Due to the high flexibility of the machines, pillow bags and gusset bags with a filling weight between 10 kg and 50 kg can be filled. The bags can be made of woven PP, PE or paper. In order to meet special requirements, the machine is also available in a stainless steel execution and can be equipped for powdery products.

Request for a quote

FERPLAST SNC

Italy

Suitable for all types of neutral or printed film (preferably with antistatic treatment) or tubular polyethylene with thickness from 0.06 mm to 0.13 mm or tubular polypropylene with from 0.03 mm to 0.05 mm thick, and cartene normal or high density. Furthermore, with the FP BAG EVO it is also possible to use expanded polyethylene (FOAM) in tubular reel with a maximum thickness of 1.5 mm. It can use reels with a width of 80-300 or 100-500 mm without disassembly of parts or changing settings. The packaging machine automatically perform the forming of the bag with the upper opening. The filling of the bag and the subsequent closing can be done manually by an operator who starts the cycle of the machine through a button, or automatically by means of feeders, manipulators, weighers. The reel change takes a maximum of thirty seconds. The machine cycle time for the preparation of a bag 200 mm long is about four seconds.

Request for a quote

FERPLAST SNC

Italy

BSL 5045 SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Angular packaging machines with manual or automatic closing of the sealing bar and motorized product unloading belt. They can be combined with a retraction tunnel. FEATURES: - Sealing blade in NI-CR with non-stick coating - Control of the welding time to avoid overheating - Conveyor belt adjustable in height by handwheel - Double magnet for high closing force - Reel holder sliding on ball bearing guides, useful width mm. 550 - Return of the sealing bar controlled by a gas spring (for the 5045 L manual version) - Pneumatic device (compressed air) for closing and opening the sealing bar (for the BSL 5045 LA semi-automatic version) The BSL 5045 LA model is equipped with a maintained action dual control (the two buttons must be held down until the bars are completely closed).

Request for a quote

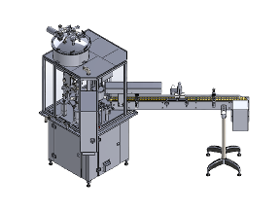

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

A full automatic packaging machine that fills in plastic containers and thermally welds them. It consists of five work stages that start with pulling the empty containers, then packing, then coverings, then welding and taking out. Suitable for medium products, with a production capacity of 1500 packages per hour.

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

Centrefold plastic film is created by slitting blown film, which is closed on both sides, at the side or down the centre, as desired. It is basically folded flat film. Centrefold film can be used for a wide variety of packaging solutions. One good example is in the furniture industry, which uses centrefold film as furniture covers to protect pieces from dirt and dust. But centrefold film also plays a major role in product packaging in other areas such as e-commerce, the pharmaceutical industry and the textile industry. Centrefold film is mostly processed using machines – especially L sealers, for example. Centrefold film is one of the most common types of plastic film used in automatic packaging machines.

Request for a quote

FERPLAST SNC

Italy

CJS 25 HI is an electronic dosing device with load cells for semi-automatic filling of bags with max weight 25 kg. Hopper capacity 300 l, bags weight 2-25 kg. The machine is suitable for the automatic dosage of granular products with a good flowability. The dispenser is mainly formed by a welded and painted tubular steel, stainless steel, loading hopper with pneumatic closing, fast discharge channel, slow discharge channel with vibrator to achieve the exact weight, weighing hopper installed on load cells, pneumatic device for locking the empty bag, PLC operator interface and user-friendly keyboard. The dispenser can be combined with a motorized conveyor for automatic loading of the product and to a free or motorized conveyor for unloading the full bag, it can also be combinated with an automatic packaging machine. All parts in contact with the product are made of stainless steel. Ideal for packaging of pellets, granulated foods, dried pasta (short), cereals, coffee, nuts, sugar, etc.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication wherever good penetration capacity is the only possibility for relubrication, for example at joints, hinges, linkages, levers and guides Lubrication of machine elements subjected to moisture, for example at conveying systems, packaging machines, automatic filling machines, etc. Chains in a dusty environment Advantages and benefits Light-coloured High lubrication effect due to optimum product formula Good creep properties, thus easy penetration even in narrow, hard-to-reach lubricating points Good lubricating and pressure absorption capacity Excellent corrosion protection Good wear protection, also in comparison to higher-viscosity oils without solid lubricants Broad range of uses in all maintenance sectors Also available as spray version OKS 671

Request for a quote

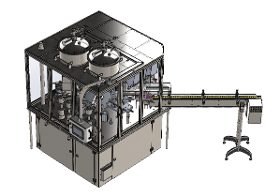

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

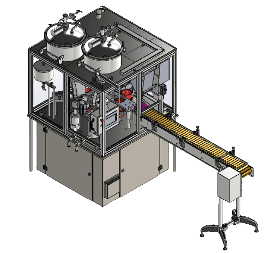

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

PACK POINT 08 - CASE ERECTOR Semiautomatic carton erector. It forms the bottom of uniform size batches of American type boxes, with operator. Operation is simple , just insert the open box in the case erector. The four bottom flaps are folded and the box is automatically locked in position for filling. A pneumatic pusher makes the expulsion of the box to a taping machine . The PACK POINT 08 when combined with a taping machine is a compact and productive semi-automatic packaging line. The machine is equipped with 4 wheels with brakes.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication wherever good penetration capacity is the only possibility for relubrication, for example at joints, hinges, linkages, levers and guides Lubrication of machine elements subjected to moisture, for example at conveying systems, packaging machines, automatic filling machines, etc. Chains in a dusty environment Advantages and benefits Light-coloured High lubrication effect due to optimum product formula Good creep properties, thus easy penetration even in narrow, hard-to-reach lubricating points Good lubricating and pressure absorption capacity Excellent corrosion protection Good wear protection, also in comparison to higher-viscosity oils without solid lubricants Broad range of uses in all maintenance sectors

Request for a quote

FERPLAST SNC

Italy

Packaging machine with automatic cycle Skinpack, for wrapping objects of small, medium or large dimensions, between cardboard and transparent plastic film. The extreme usability and the use of unskilled workers encourage the use of this machine. The package Skinpack allows you to see the product immediately, it gives you the opportunity to advertise in color and include information on the carton, convenience of packaging that can be hung in the exhibitors. Given the high power of the machine is possible to use unperforated cartons.

Request for a quote

PEKU FOLIEN GMBH

Germany

Zipperbags are almost airtight, frequently reusable and withstand heavy loads. Therefore, zipperbags are ideal for long term use. Our pressure lock bags or zipperbags are easy to open and to re-close and protect the content from contamination or loss. They are suitable for packing all sort of goods, e.g. small components for technical or household devices, as well as foodstuff or cosmetics. Transparent, reclosable zipperbags are also used in security areas of airports. If hanging storage is required, the zipperbags are available with euroslots. To ensure safety and integrity of the content, a tear perforation can be integrated in the bag. Zipperbags can be filled manually as well as automatically. Therefore, all zipperbags are available as wicketed bags, for automatic or semi-automatic packaging on your machines. Like all our packaging solutions, our zipperbags are available in nearly every quantity

Request for a quote

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

CDA

France

CDA’s Ninon Mix facilitates adhesive labelling on the sides and tops of square, cylindrical, ovalized, and conical products without requiring any material changes. This linear automatic labeller boasts the capability to apply up to 5 labels, with a labelling capacity reaching up to 60 products per minute depending on the packaging. The Ninon Mix stands out for its versatility and streamlined touch screen management, making it seamlessly integrable into a complete packaging line. This automatic labelling machine accommodates all formats and finds applications in various sectors, including: Food processing (sauce, honey, jam, oil, vinegar, mustard, etc.), Cosmetics (cream, perfume, body oil, soap, shampoo, etc.), Paint and varnish (buckets, cans, jars, etc.), Chemistry (dishwashing liquid, detergent, solvent, household products, etc.).

Request for a quote

BISS

Poland

Bread is one of the most widely-consumed products. Thereby, we want to create packaging that let us enjoy the freshness and taste of traditional bakery goods even longer. High transparency and gloss of foil ensure a fine display of packed bakery products. The packaging is intended for use with automatic packaging machines.

Request for a quote

BISS

Poland

We offer a film for packaging various fresh fruit, including lettuce, carrots, potatoes, onions, bell peppers, in the form of LDPE and BOPP tapes, and BOPP/LDPE laminates for automatic flow pack packaging machines. The offered films are widely-used in agriculture and food industry, and in horticulture.

Request for a quote

BISS

Poland

We offer a film for packaging various fresh fruit, including apples, pears and citrus fruits, in the form of LDPE and BOPP tapes, and BOPP/LDPE laminates for automatic flow pack packaging machines. We also have ready-made bags to be used in agriculture and food industry, and in horticulture.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The target weight is controlled by linear vibration units. With respect to product type and desired speed; 2 or 4 line types are available. The magnitude of vibration level for each line is adjustable. The accuracy of each filling is controlled by tuning each line vibration magnitude. The average accuracy is depend on product type. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continiously. Auotamic lateral adjustment of wrappin material. Suitable for CE standarts. 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlled with fast and accurate servo driven specific auger (worm screw). The auger type and diameter Changes with respect to product type and target weight. All surfaces touching to products are AISI 304 stainless steel. · Sutiable for quadseal packages · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. · Printer state is checked continiously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. · Wrapping material tension is controlled continiously. · Auotamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

Suitable for granule type of products. The weighing unit is controlled by a seperate microprocessor and touch screen.Supports many usefull functions such as multi dumping, automatic product conveyor control, self cleaning, recipe record for different products, different language and etc. Different amount of weighing buckets in different dimensions should be provided with respect to type of product. Parts touching to products are easy to dismount and cleaning. All surfaces touching to products are AISI 304 stainless steel. Sutiable for quadseal packages Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continously. Wrapping material is feed by Servo motors. Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continously. Auotamic lateral adjustment of wrappin material.

Request for a quoteResults for

Automatic packaging machine - Import exportNumber of results

65 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (21)

- Food industry packaging machinery (11)

- Food packaging (4)

- Automation - systems and equipment (3)

- Package sealing machinery (3)

- Custom packaging (2)

- Packaging (2)

- Paper and cardboard manufacturing - machinery and equipment (2)

- Silicones (2)

- Agriculture - Machines & Equipment (1)

- Bag filling machinery and equipment (1)

- Bags, plastic (1)

- Cleaning, industrial (1)

- Films for packaging (1)

- Food Industry - Machines & Equipment (1)

- Food industry - machinery and equipment (1)

- Glues, adhesives and applicators (1)

- Industrial robots (1)

- Labelling machines (1)

- Livestock raising - machinery and equipment (1)