- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic heat sealers

Results for

Automatic heat sealers - Import export

TBT MEDICAL - TURQUOISE BIOMEDICAL TECHNOLOGIES

Turkey

Sealing solutions for every kind of work load PLUSEAL series impulse & rotary sealers are designed to meet the needs of medical professionals active in surgeries, CSSD’s and dentistry clinics. Correct packing process, including perfect sealing quality, is critical for ensuring sterility until the instrument is used for the patients. To lower the risks of infection, to ensure hygiene for operators and patients and to maintain the sterility of instruments until the right time; packing is a crucial step that should not be ignored. Our range varies from basic impulse sealers to rotary sealers with digital control and even further to rotary sealers with printer and touch screen. Sealing speed for rotary sealers are up to 14 m/sec while models with printer it is optional to have 2 line printing.

Request for a quote

FERPLAST SNC

Italy

Machine suitable for the closing of bags with height, mm. to 150 mm. 270 and max weight. 3 kg. The welding system with belts PTFE allows for closing of bags made of polyethylene, polypropylene, cellophane, coated paper, laminated aluminum, etc. The temperature is adjustable from 0-250° C. and the feed speed is adjustable from 0 -12 mt. / min.The welding head is adjustable in height and the distance between the welding and the edge of the bag is 10 mm. The machine is equipped with rotary solid ink marker and interchangeable characters (up to 20 characters with a height of 5 mm.), The system works with inked rollers for easy management and is complete with a photocell to do the marking in the desired location. This model is constructed in the standard version, that is, the advancement of the product occurs from right to left.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Sealing bar type BS for sealing and closing bags: - From PE - From PP - From soft PVC - From polyamide PVC Features: Equipped with a potentiometer for setting the welding time and a high-quality welding rod. The BS...C models are equipped with a manual cutting blade. The BS...CF models are equipped with a round welding wire cutter.

Request for a quote

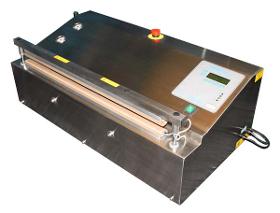

FERPLAST SNC

Italy

Semiautomatic table top sealer with electric pedal and impulse sealing bar (resistance is heated for a few seconds), suitable for closing bags of plastic material heat-sealable. The closing of the sealing bars by pressing the pedal electric with solenoid allows the operator to have both hands free and for increased production, just select the automatic cycle with timed closure. The timers for adjusting the welding and cooling ensure maximum reliability of each type of material. Simple to use, requires no preheating. Maximum thickness. weldable 0.20 mm. (0.40 mm. Overall)

Request for a quote

FERPLAST SNC

Italy

Impulse sealers MG 621 series, with 620 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. The MG 621 series sealing machines are available with mechanical or motorized closing bars with 3 or 5 mm sealing thickness depending on the model. Also available in stainless steel with mechanical closure of the bars and and 3 mm sealing.

Request for a quote

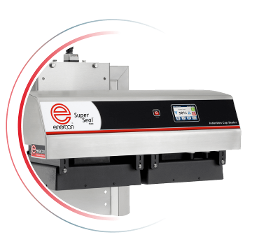

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Auto Junior semi-automatic induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. The quality, reliability, and safety and support of Super Seal™ Auto Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Fully adjustable table-top stand • Diameter 20-63 mm • Digital timer • Missing foil indicator • 500W output • Dimensions 17.8mm W x 30.0mm D x 38.0 cm H

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Junior manual induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. Our unique coil design facilitates the sealing of a wide range of caps including flat, sauce dispensing and conical caps, at diameters from 15 – 150mm. Other hand-held devices will only seal flat caps. The quality, reliability, and safety and support of the Super Seal™ Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Handheld and portable • Cap size 15-150 mm • Batch and foil counter • Digital timer • Missing foil indicator • 1KW output

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

This single coil induction cap sealer offers users increased productivity, an easier set-up and more control. The easy-to-use touch screen is available in multiple languages. The Super Seal™ Touch is our most powerful compact single-coil machine and is designed for production lines running at up to 40 metres per minute. The air-cooled power pack is separate from the induction sealing coil. • Pre-programmed and fully integrated touch screen control for inspection and rejection • Remote start/stop and remote power control (auto start function available) • Password protection with operator lockout • High and low level set power alarm • Recipe management • Internal monitoring of all critical operating data • Diagnostic system information • Internal USB data port – Network connectivity available • Stainless steel IP55 enclosure • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

Available in three models Super Seal™ 300 Super Seal™ 400 Super Seal™ 600 We have built on the proven design of the Super Seal™ range of induction cap sealers, to bring new features to give more value to packagers. The new Super Seal™ compact induction cap sealers are available in three power levels. There are a variety of sealing heads available to optimise sealing performance for your specific applications. •New display simplifies setup, operation & troubleshooting •Local/Remote modes for start/stop & power level •Seals a variety of caps ranging from 20 – 150m •System settings in a single level menu •High efficiency plug-in induction sealing coils to maximise performance and minimise energy costs •Compact and air-cooled •Power supply electronics are housed in an IP55 enclosure •Fully compliant with all UK and European regulations •Fully adjustable stainless-steel stand for different container heights

Request for a quote

FERPLAST SNC

Italy

CF SERIES - CONSTANT TEMPERATURE HEAT SEALERS WITH PEDESTAL AND FOOT PEDAL ( for multi-layer bags) THE CF SERIES of constant heat sealers with pedestal and operated by foot pedal, are ideal for sealing bags made of compunds, multi-layer films, co-extruded films, OPP, heat-sealable cellophane. It is not suitable for polyethylene films. Being operated by foot pedal, the hands are free to feed the machine. The sealing jaws of the type "hot bar" are equipped with resistance and temperature controller for controlling the temperature from 30 ° C to 200 ° C. The temperature of the sealing jaws is adjustable according to the type and thickness of the material to be sealed, and is kept constant by a heat thermo-regulator. The maximum sealable thickness, that always varies according to the type of sealable material, is 0.25 mm. (50 mm. total). Also available in CFN version with timer and acoustic signal at the end of sealing.

Request for a quote

FERPLAST SNC

Italy

ME-FDE SEALERS WITH DOUBLE MOTORIZED PULSE SEALING BAR AND TEMPERATURE CONTROL The new bench sealers with double impulse sealing bar and temperature control, allow the optimal sealing of any type of envelopes and sealable bags. The high pressure exerted by the motorized descent of the bars (0.7 Kg./cm2) allows perfect sealing even on very thick materials. The double active motorized sealing bar (heats above and below) and the 5 mm sealing they allow the closure of envelopes with high thickness, laminated and envelopes with bellows. In addition to sealing polyethylene, polypropylene, coupled paper, aluminum, pvc and medical bags, it also allows the sealing of advertising banners. To seal the banners, we recommend sending samples, without obligation, to carry out the sealing tests. Maximum sealable thickness 0.20 mm (0.40 tot). Timers for regulating the sealing and cooling temperature ensure maximum reliability on all types of material.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Max is the fastest inline sealer on the market, with a dual coil it’s designed for high-speed packaging lines running at up to 100 metres per minute. This dual coil air-cooled induction cap sealer offers increased power and a multi-language touch screen for a simpler operation. It delivers reliable sealing with a diverse operating window that compensates for cap, liner and container tolerance variations. • Multiple language selection • Easy to use touch screen • Supervisory password protection with operator lockout • Recipe management • Internal monitoring of all critical operating data • Container, cap and foil counters available • Local and remote start/stop and power control • Stainless steel IP55 enclosure • Remote network control and monitoring via RS485 or Ethernet • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm • Fully compliant with all CE regulations

Request for a quote

FERPLAST SNC

Italy

Impulse manual bag sealers machines FPS series are the simplest and most economical series of sealers machines. The model FPS-C is equipped with a cutter for trimming the envelope. This system allows you to pack products with different lengths and then performing the trimming of the bag, leaving no protruding edges and unsightly. This model is only available in sizes 300 and 400 mm. The sealers FPS/FPS-C are suited to a medium-low production and allow the closing of plastic bags without folding, with maximum thickness of 0.15 mm (0.30 mm total). The sealing is by impulse (the resistance heats for a few seconds) and can be adjusted by timer. The sealing cycle is generally 3 seconds and is indicated by an indicator light. These sealers has a sealing width of 2 mm.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The benefits of induction technology in a capless sealing process. Successful sealing on both capless and non-screw-cap containers such as snap on caps is now possible with a pressure Sealer incorporating an Enercon Super Seal™ unit. Typically, pressure belt sealing is used to replace conduction sealing or to reduce the dwell-time needed in conduction sealing. Seals are either placed onto the capless containers or reside in the cap as inserted by the cap manufacturer. The capped container is then guided through the induction heating tunnel, where downward pressure is applied to the clip-on cap or foil by a non-metallic recirculating belt. This unique design automatically takes account of component variations and tolerances, such as bottle height variation, product overfill, line speed variation and bottle centres. Incorporates an Enercon Super Seal™ unit • Cap sizes up to 110mm diameter • Conveyor Speed up to 40 metres / minute

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 96 is available as a bench mounted or free-standing bag sealer, designed for sealing bags when the product can be laid down. The Star 96 is the industry standard, sealing a whole host of products ranging from pet bedding to pharmaceutical supplies. The Star 96 is solenoid operated as standard, with foot switch operation. The solenoids close the jaws and keep them closed for the duration of the weld and cool cycle, allowing the operator to prepare the next bag. If the machine is being used quickly, the Star MkVI timer board can be set to compensate the heat built up. A variety of product support tables and machines are available on request. Constant heat machines are available for special bag materials such as paper bags. For the sealing of medical and pharmaceutical products, the Star ARTICS controller can be specified to give unparalleled seal quality and consistency.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 66 free-standing sealer is designed specifically for sealing bags where the product is best standing upright. Typically, this lends itself to the bagging of bulk product such as aggregates, prepared foods and chemicals. The Star 66 is available in a range of formats to suit the product, working environment and bag type. The rugged, powder coated mild steel body is built to withstand the rigours of hostile working environments, such as builders' yards or coal merchants. The foot switch initiated solenoid jaw operation allows the operator to be preparing the next bag whilst one is being sealed. An IP65 stainless steel machine is available for food environments. Constant heat jaws for heavy weight foil and multi-wall bags are also available. For applications where seal quality is paramount, such as hygroscopic compounds, the Star MkVI C or ARTICS controller should be specified.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Medical sealers have been developed for applications where ease of cleaning is critical, such as in the food, medical and pharmaceutical industries. The machine body can be built in a number of different designs with the jaws operating vertically (when a product is best sealed laying down) or horizontally (when a product is best sealed standing up). With the cylinders moving the top jaw directly, jaw alignment and pressure are much more controllable. This machine design is available with all the Star controllers. The Star Medical Vacuum sealer allows for the air to be removed from a bag prior to sealing. The machine is available with a range of vacuum pumps or vacuum generators dependant on your application. Gas flushing is available for modified atmosphere packaging. This machine design is available with either our ARTICS or Medical controllers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 56 range of bag sealers consists of a power pack and a set of sealing jaws designed for heat sealing products in situ or for a bag sealer to be incorporated into a parent machine. The range of sealing heads is ideal for uses such as sealing valve sacks, foil or plastic machinery covers and sealing straps onto bulk bags. We also produce a range for sealing dangerous/ toxic products where the seal incorporates a cut so no product can escape. Seal cycle initiation can be via foot switch, push button or automatic (when the jaws are closed). The power pack is connected to the jaws by a lead, allowing the jaws to be used in awkward positions. Adjustable weld and cool timers control the sealing cycle, allowing them to be used on most materials. The indicator lights on the power pack or sealing jaws advise the operator when the weld and cool cycle are complete. Special sealing heads producing shaped welds can be made for almost any application.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Platen Sealer is available either bench-mounted or free-standing, producing shaped or multiple welds. The Star Platen Sealer can be manually or pneumatically operated with either foot switch or push button operation. The Star Platen Sealer can seal most modern plastic, biodegradable, foil, paper and laminate packaging materials and is constructed from anodised aluminium profile to give rigidity whilst keeping the weight down. The Star Platen Sealer is available with: A variety of seal shapes, sizes and widths Multiple seals can be produced at the same time Automatic cutter for a straight or shaped cut out A variety of jaw openings dependant on application Interchangeable sealing heads for different welds from the same machine Either one or both jaws heated A range of control options are available including the ARTICS and MkVI C controllers

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the (WHO) guideline as well as the current guideline of the (WFHSS). CE Certified, provides verifiable sealing according to EN ISO 116072 and international guide ISO/TS 16775 • Body All Stainless White oven painted • Display Adjustable constant temperature system with digital display • High speed Capacity to process pouches at 11 m/min • Sealing type and width MultiLine sealing, 14mm. • Special coating on heaters New technology system without Teflon® fabric on heaters, which is old technology and requires frequent replacement, Technical Service and Spare Parts • Device safety Emergency Back, Emergency Stop and Emergency Back buttons. If the pouch gets stuck in the device, it prevents it from melting inside and disrupting the work. • Easy serviceability easy access to parts thanks to modular device structure • Maintenance periyod 1 time per year • Warranty 2 Years • Lifespan >15 years.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the World Health Organization (WHO) guideline as well as the current guideline of the World Federation of Hospital Sterilization Sciences (WFHSS). CE Certified, provides verifiable sealing according to EN ISO 116072 and international guide ISO/TS 16775 • Body All Stainless White oven painted • Display Adjustable constant temperature system with digital display • Control With Microprocessor • High speed Capacity to process pouches at 11 m/min • Sealing type and width MultiLine sealing, 14mm. • Special coating on heaters New technology system without Teflon® fabric on heaters, which is old technology and requires frequent replacement, Technical Service and Spare Parts • StandBy If no pouch is supplied to the device, 15 seconds. after mechanism stop, mechanical protection • Device safety Emergency Back, Emergency Stop and Emergency Back buttons. If the pouch gets stuck in the device, it prevents it from melting inside and disrupting the work.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the (WHO) guideline as well as the current guideline of (WFHSS). CE Certified, provides verifiable sealing according to EN ISO 116072 and international guide ISO/TS 16775 • Body All AISI 304 Stainless Steel • Display Adjustable constant temperature system with digital display • Control With Microprocessor • High speed Capacity to process pouches at 11 m/min • Sealing type and width MultiLine sealing, 14mm. • Special coating on heaters New technology system without Teflon® fabric on heaters, which is old technology and requires frequent replacement, Technical Service and Spare Parts • StandBy If no pouch is supplied to the device, 15 seconds. after mechanism stop, mechanical protection • Sleep Mode® If the device is not used for a long time, after the desired (adjustable) time, shutting down the entire system including the heaters, energy saving. Note It was applied for the first time in the world by Gündem in 2009.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the World Health Organization (WHO) guideline as well as the current guideline of the World Federation of Hospital Sterilization Sciences (WFHSS). It provides verifiable sealing action according to EN ISO 116072 and international guide ISO/TS 16775. It documents this in writing with the Validation Report at each first use or when requested. • 4,3” color touchscreen and multilanguage • Login No password or password protected login for 5 users • Interactive monitoring Temperature, pressure and speed control and display on the screen • High speed Capacity to process pouches at 11 m/min • Sealing type and width MultiLine sealing, 14mm. • 9999 product/set memory Expiry date, Bag width and Barcode record for each product/set separately • Straight or reverse writing, permanent, temporary counter and countdown, LOT, CE, STEAM, VH2O2, EO, LTSF, STERILE symbols and Barcode • WriteMatic® Ability to print long texts by fitting the width of the pouch

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic L Sealer Shrink Wrap Machines are widely used in the assembly line of mass production and packaging. It is suitable for products of different widths and heights. It uses an electronic eye to detect products when they pass through the conveyor. After a product passes the sealing arm, the seals fully enclose the product in shrink film. After the seal, products continue to pass into the shrink tunnel. The shrink tunnel has recirculating heat to shrink the film to the product evenly. Fully wrapped products exit the tunnel, and the film is conformed tightly to the product. Using the original "OMRON" digital temperature controller with built-in PID function, the temperature of the sealing knife is extremely sensitive and accurate, and can be set at will. The sealing knife itself also has an automatic protection function, which can effectively prevent miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This roller conveyor is ideal to prevent the packages from being damaged or torn by rubbing against the table during the packaging of the products in the devices. At the same time, there is no need for personnel to hold the packages along the device as the packages move through the device. • It has a stainless steel case and easily rotating plastic bearings. • Dimension (L x W x H) 560x 260 x 50 / 150mm (Height Adjustable) • Weight 4 Kg • Designed for 05GD, 08GM and 09GM model sealers.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This front table is ideal for preventing the packages from being damaged or torn by rubbing against the table during the packaging of the products in the devices.. • Cut pouches do not mix with each other. • When the cutting is finished, the pouches are easily put into a bag or wrapped with paper tape. • In order to prevent the paper tape from being opened (in 40GM model device), a label taken from the thermal printer and containing the desired information is attached. • The connected pouches that are put into stock do not scatter or get lost, information such as which product/set they belong to and their number, LOT number, etc. can be seen. • If a Barcode is defined for the products, all the ties in the stock can be counted very easily thanks to the Barcodes printed on the label. • It is AISI 304 stainless steel. • Dimension (L x W x H) 563 x 274 x 67 mm • Weight 2.8 Kg • Designed for 28GM, 30GM and 40GM model Pouch Making Sealers.

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

It meets the requirements of the World Health Organization (WHO) guideline as well as the current guideline of the World Federation of Hospital Sterilization Sciences (WFHSS). It provides verifiable sealing action according to EN ISO 116072 and international guide ISO/TS 16775. It documents this in writing with the Validation Report at each first use or when requested. • Computerbased, 7” color touchscreen and multilanguage • Login No password or password protected login for 5 users • Interactive monitoring Temperature, pressure and speed control and display on the screen • High speed Capacity to process pouches at 10 / 12 / 14 or 16 m/min • Sealing type and width MultiLine sealing, 14mm. • 9999 product/set memory Expiry date, Bag width and Barcode record for each product/set separately

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• In Full Automatic Rotary Sealers and Pouch Makers, when the target number of pouches is reached, the total number of pouches/packages, their contents, Institution Name and Logo can be read and written on the label as Barcode / QR Code. • Labels obtained from the thermal printer also serve to seal the box in which the produced bag/packs are placed. • These labels can also be printed individually for each Pouch/Pack produced in the Sealing Device. • The print on the labels is not erased in hot environments (especially in an autoclave). • These labels are available in versions with Steam, Ethylene Oxide, H2O2 (Plasma) indicator and without indicator. • This printer is suitable for 20GM, 40GM, 46GM and 60GM model devices

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

• Provides a very large workspace on the desk • Can be easily mounted on the mobile table or desk, • A065 model Manual Roll Cutting Apparatus can be mounted on the stand. • Designed for 10GM and 20GM model Rotary Sealers in this case the device can operate. • On request (optional) Side Rack Set (A030) can be mounted on both sides of this stand. Pen Holder and Indicator drawer are included in the Side Rack Set • The stand is painted with a stainless furnace and the top is AISI 304 stainless steel. • Dimension (L x W x H) 750 x 303 x 248 mm • Weight 5 Kg

Request for a quoteResults for

Automatic heat sealers - Import exportNumber of results

32 ProductsCompany type