- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic cutting

Results for

Automatic cutting - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

An idle cut blade head with automatic cutting gap adjustment ensures that the Weber Slicer 604 has a high yield with minimum giveaway. The product throat can be adjusted automatically in height and width, and the fully automatic central loading unit ensures rapid product changes. Products up to 1,700 mm in length are fed in automatically and processed at up to 600 slices per minute. The shear bar and side limit stop can be configured by motor and with programme control. That allows the Weber Slicer 604 to guarantee a precise cut and placement of perfect slices continuously. Options: Slice folder Variogripper Idle cut blade head Separate blade drive Interleaver Portion designer

Request for a quote

IMETA SRL

Italy

Semiautomatic seam saw for the automatic cutting of any type of can. Features include electropneumatic operation of blades with adjustable advancement, total retraction of blades if the protective cover is opened, modular fittings for can blocking, CEstandard protection and high soundproofing. Mono or triphase motors available.

Request for a quote

COSTRUZIONI METALMECCANICHE VALENTE

Italy

Our staff, who are specially trained and kept constantly up-to-date with the latest developments, produce special and automatic machines, production lines and industrial plants, automation and handling systems, prototypes and newly developed machines, material handling and automation systems, equipment and lines. The on-site engineering department at the Nole plant provides specialist consulting on the production of ad hoc industrial machines and systems, which are designed according to customer requirements using advanced 3D design software. Below are some examples of machinery produced : Equipment for the production of foam rubber Automatic cutting lines for rubber Industrial washing facilities Drying ovens Inspection machines Newspaper sorting plants Polymer tempering plants Rolling mills for pasta and kneading machines

Request for a quote

EACTECH®

Portugal

The Tecno Freccia automatic cutting unit is ideal for small and medium productions. Its cuttingedge technology allows cutting the most varied types of materials such as PVC, fiberglass or carbon fiber.

Request for a quote

EACTECH®

Portugal

Automatic cutting unit ideal for the automotive industry. Designed for high cuts, but also suitable for other types of material.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic mitre bandsaws from BEHRINGER are saws to really get things moving. Particularly when it comes to classical series production such as cutting to fixed lengths and mitre sawing in automatic mode. And also when cutting layers and packages they make a good impression. By their excellent cutting performance and short nonproductive times, your productivity can be increased significantly. Using an NC controlled feed gripper in conjunction with an NC controlled saw frame mitre box, fully automatic mitre cuts can be performed on both sides. The PC control system provided as standard makes for extremely simple menu-prompted operation of the saw and peripheral devices. The BEHRINGER mitre bandsaws contain many useful features already in the basic price: - Convenient PC control - Fast NC-controlled mitre system - Vertical clamping unit - NC-controlled feeding gripper with 3.000 mm feeding length in single stroke - Spray mist cooling system

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

This Behringer's semi-automatic straight-cutting bandsaws combine the high-cutting output and simple handling which are utilized for economical processing of low piece numbers and one-off cuts. They feature easy handling that are precised in isolating the easy and difficult cuts. These machines are suitable in cutting pipes and all the materials which contain difficult machining properties and they can also provide semi-automatic variants that are recommended for the accurate positioning of a longer cut piece.

Request for a quote

MONGIN

France

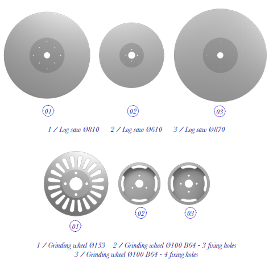

TYPE OF MACHINES : PERINI, PCMC, FUTURA, ... Depending on your converting process, the hardness and abrasivness of your products, we manufacture log-saws : Ø610 / Ø810 / Ø870. Standard bores : 68.26 / 82.55 mm. Short and long bevel : 190 / 230 mm. To obtain a clean and precise cut with an automatic sharpenning, we supply grinding wheels adapted to your machines. 1 / Log saw Ø810 2 / Log saw Ø610 3 / Log saw Ø870 1 / Grinding wheel Ø153 2 / Grinding wheel Ø100 B64 - 3 fixing holes 3 / Grinding wheel Ø100 B64 - 4 fixing holes

Request for a quote

CROMMAC MAKINA METAL IMALAT SANAYI VE TICARET LIMITED SIRKETI

Turkey

Crommac Portanar Semi-Automatic Orange Juicing Machine Area of Use It is used for squeezing orange, grapefruit, tangerine and lemon fruits. General Features Portanar Semi-Automatic orange squeezing machines; It is designed to extract the juice of fruits such as oranges, tangerines, grapefruits and lemons in places such as restaurants, hotels, entertainment and shopping centers, dormitories, universities and buffets. It automatically performs feeding, cutting and squeezing operations when the machine is started. It is very easy to use. It is a hygienic and safe machine. Capacity to squeeze 28 oranges per minute Possibility of squeezing fruits with diameters between 65mm and 80mm. Possibility to store 7 kg of oranges in the fruit chamber 15 kg fruit pulp collection bucket Possibility to store 6 to 8 oranges in the fruit runner Safety switch that stops squeezing when the lid is removed

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The special model ASW 560 for industrial applications offers the latest technology and premium quality: Combine cutting or flattening in conjunction with the Weber automatic initial cut function in one machine. That means that virtually no manual post-processing is required after the processing workflow, even for cheek and very cold material. Can optionally be used with a blade shaft for cutting into the product to be derinded. That leads to an optimal derinding result with a residual rind of less than one percent (temperature dependent) for pork cheek or use with upstream pressure device (roller) instead of the blade roller. Advantages Two work procedures in one machine increase product throughput Almost no more manual post-processing required, even for pork cheeks and highly cooled materials – potential labour savings Options: Operation from left or right Product-specific pressure devices for the derinding process Special sub-frames (height adjustment)

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Economical and versatile: the ASB 400 conveyor derinder with a wide range of applications. The entry-level model can be used (open) as combination machine with carriage table or (closed) with pressing unit and conveyor. Automatic derinding of all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Clean removal of rind without residues Infinite adjustment of the rind/cutting thickness Ergonomic machine design: short setup times, simple operation with maximum safety Options: Pressure rollers in various hardnesses Special voltage

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The wide product throat in Weber Slicer 405 guarantees a high output, and the shear bar and side limit stop can be configured individually for the product width. Product change is manual and rapid, even with short products. Manual and automatic loading are available as options, and end pieces are ejected automatically. Thanks to Weber Hygiene Design, Slicer 405 is simple to clean. Options: Automatic loading Idle cut blade head Separate blade drive Clearance height infinitely adjustable Interleaver, Interleaver Speed Plus Portion designer

Request for a quote

FERPLAST SNC

Italy

Wrapping machines with rotating ring series RING BOX EVO with automatic hook/cut of the film automatic and manual advancement, for the packaging with stretch film of sections, bars, boards and products with elongated shape. Practical and economical, allow to lower operating costs thanks to low consumption of energy and materials. The introduction of the products to be packaged is manual and is made by sliding them on a idle roller conveyor. By a foot pedal, is carried out the winding of the film on the product to the desired time; at the end of the cycle, with a slight movement of the pack, is obtained the cold-cutting of the film. All operations are controlled by PLC.

Request for a quote

PRESSTA EISELE GMBH

Germany

Tooth belt drive with profile slide Available for following automatic cutting machines: Profilma 200, 250, 500E, 510E, 600R Max. load 750 KG Dimension of stories fix, e.g. max. cutting range of the saw Conveying length 1.850 mm Profile length from 2.700 – 10.000 mm Pneumatic gripper for good feeding of the profiles

Request for a quote

PRESSTA EISELE GMBH

Germany

Tooth beld drive – with storages Available for following automatic cutting machines: Profilma 200, 250, 500 E Max. load 8 storages Max. square 50 x 80 mm Max. weight 3 kg / m Profile length 2.100 – 6.500 mm Pneumatic gripper for good feeding of the profiles

Request for a quote

PRESSTA EISELE GMBH

Germany

Available for following automatic cutting machines: Profilma 250, 500 E, 510 E, 600 R Top loading by crane or fork lift Max. bundle Ø 650 mm Max. load 4.000 kg Bar length 3.000 – 6.200 mm Pneumatic gripper for good feeding of the profiles

Request for a quote

TEMCA GMBH & CO. KG

Germany

The automatic towel roll dispenser celtex® sensor has a viewing window for filling level indication. The dispenser automatically cuts Airlaid as well as tissue. celtex® sensor consists of plastic and is lockable. Possible adjustments: time delay for paper feed and paper length. It is suitable for Airlaid tissue-towel rolls up to a max. width of 200 mm and a diameter of 200 mm. The dispenser is available in white and black.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TEMCA GMBH & CO. KG

Germany

The hand towel rolls dispenser celtex® autocut has a viewing window for filling level indication. The dispenser automatically cuts Airlaid, as well as tissue rolls. celtex® autocut consists of plastic and is lockable. It is suitable for Airlaid and tissue hand towel rolls up to a maximum width of 220 mm and a diameter of 200 mm. The length of the towels is 280 mm. This dispenser is available in white and black.

Request for a quote

TEMCA GMBH & CO. KG

Germany

The hand towel rolls dispenser celtex® autocut has a viewing window for filling level indication. The dispenser automatically cuts Airlaid, as well as tissue rolls. celtex® autocut consists of plastic and is lockable. It is suitable for Airlaid and tissue hand towel rolls up to a maximum width of 220 mm and a diameter of 200 mm. The length of the towels is 280 mm. This dispenser is available in white and black.

Request for a quote

PRESSTA EISELE GMBH

Germany

Chain conveyor for heavy profiles Available for following automatic cutting machines: Profilma 510 E, 600 R Max. load 5.300 KG Dimension of stories fix, e.g. max. cutting range of the saw Conveying length 1.550 mm Profile length from 500 – 7.000 mm Pneumatic gripper for good feeding of the profiles Buffer storage in front of the loader Infeed of material by driven belts

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation cutting of aluminium and non-ferrous metal NC Control with touch screen display 5,7” Piece counter showing target/actual number of pieces Piece multiplier when cutting bundles Indication of cycle time Multiple feed device – max feed 3.250mm Table separation before the saw blade retracts so the profile is not touched by the saw blade Electronic material feeder, ball screw spindle and servo motor incl. pneumatic horizontal and vertical clamps Float mounting feeder to balance bend profiles Waste piece from 85mm Reducer of clamping pressure horizontal and vertical Cycle spray mist device with level indicator and automatic stop Cut-off length from 3mm Automatic cut-out when bar is finished Technical Data: Motor up to 18,5kW, S 6 40%, 400 V, 50 Hz, 2850 R.P.M. r.p.m. infinitely adjustable Saw blade speed 3.500 – 5.800 R.P.M Saw blade Ø 400mm Profile width max 200mm height max 120mm

Request for a quote

FERPLAST SNC

Italy

FPX800 LEVER HAND DISPENSER - FOR GUMMED PAPER Manual dispenser suitable for measuring and cutting the gummed paper. Lever operation. Equipped with automatic cutting blade and water tank. The length of the paper strip is adjustable by lever with adjustable stroke. By simply pressing the lever, a strip of wet paper is obtained, ready to be applied to the box. The wetted paper ensures a much higher seal than the adhesive tape and provides a clear indication on the tampering of the box. Unlike the adhesive tape, to open the box it is necessary to break the paper and it is not possible to close it again.

Request for a quote

FERPLAST SNC

Italy

The operator wrap the product with the strap, put the two ends through the buckle and places into the strapping tool. The first end is locked with the brake while the second is placed under the cutter and inside the tension roller. Increasing the tension of the strap, the buckle keeps the tension. After reaching the desired tension the strap is cut automatically by the tensioning device.

Request for a quote

FERPLAST SNC

Italy

Compact table-top Electronic Pressure Sensitive Tape Dispenser that delivers accuracy with the touch of a button. The dispenser can utilize various pressure sensitive tapes, including masking tape, Scotch® tape and strapping tape, making it ideal for sub-assembly areas and small package sealing. The PS2A will maintain the integrity and superior quality standards that have made Better Packages, Inc. a leader in the manufacturing and packaging industry. Special Features and Functions: - Automatically dispenses and cuts tape to the exact pre-set length. - Special adjustable core allows for 1" to 3" tape core sizes. - Color-coded, smooth touch keypad for ease of use. - Heavy-duty, 5-foot long electrical cord. - Grounded for enhanced safety.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

FERPLAST SNC

Italy

Wrapping Machine Mod. FP 15 SE/T with table cut for loading and unloading with pallet, and safety photocell, photocell height sensing pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (machine CE). NOTE: the machine is loaded from the side. When ordering, with a surcharge, it is possible to obtain the modification for the front load. UPON REQUEST WE CAN MAKE WITH WRAPPING MACHINES: Rotary table diameter mm. 1800 (pallets up to 1300x1300 mm)Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quoteResults for

Automatic cutting - Import exportNumber of results

142 ProductsCountries

Company type

Category

- Industrial cutting machine tools (13)

- Sawing machine tools (10)

- Automation - systems and equipment (8)

- Packing and packaging - machinery and equipment (8)

- Cutting, plastics - machinery (4)

- Food Industry - Machines & Equipment (4)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (4)

- Mechanical engineering - custom work (4)

- Milking - machinery and equipment (4)

- Shearing machine tools (4)

- Bag filling machinery and equipment (3)

- Cutting - steels and metals (3)

- Double glazing (3)

- Laser - cutting and welding machines (3)

- Meat processing machines (3)

- Sealing and wrapping - machinery and equipment (3)

- Farm machines (2)

- Grinding - machine tools (2)

- Oxygen cutting - machines (2)

- Animal feeding equipment (1)