- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automated welding

Results for

Automated welding - Import export

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

It's suitable for MIG/MAG automate processes in heavy fabrication industries. There are four adjustable parameters (oscillation width, oscillation speed, oscillation dwell time on both ends) which controlled by simple control panel.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Turn Table, precisely provide to welding by turning clockwise or counterclockwise of parts connected to it horizontally. It also enable movement in the rotation axis. . The work table is operated with a T-slot turntable to ensure that the workpieces are fully fixed to the work table. It is designed with the aim of increasing efficiency, eliminating the need for welding in difficult positions and considering ergonomics of employees.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

There are hydraulic pressing clamps in the fixture equipment of system. The workpiece is both made spot welding by means of clamps and prevented distortion due to heat during welding. Separate control lever is used as to be put to rear of piston for each piston.Also there is a pressure relief valve on each control lever. Thanks to pressure relief valves the critical pressure is brought to the desired pressure and the compression of the material in desired strength may be achieved A lock valve is connected to each hydraulic cylinder after the tightening process and during the welding operation, the material is prevented from being retracted and opened due to heat input. Reverse deflexion may be done on the frame thanks to the control units in the clamp mechanisms. 1 inert gas arc welding machine will be used for spot welding process.( it will be supplied by the purchaser)

Request for a quote

2K WELDING TECHNOLOGY MACHINE MANUFACTURING

Turkey

The 2Kwelding CBS series of column & Boom Manipulators are specially designed and produced for harsh and rugged area circumstances. Column-Boom Systems are manufactured to ensure ergonomics during weld jointing processes, reaching to hard to access areas while welding large pieces and to perform welding with minimal error.. Column-Boom systems approach to the most suitable area on the piece for performing the required welding process under control of the operatör and welding operation is performed with the command sent to the automatic unit on the boom While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

COPIER MACHINERY

Netherlands

The core of the Rotoweld technology is its unique vision-based penetration control system. It enables any operator to perform high-quality girth welds after just a few hours of training. Like the welder’s eyes and hands, the system continuously analyzes the image of the root weld pool picked up by a video camera integrated into the welding arm. Unique algorithms use this information to adjust welding parameters, such as travel speed, wire feed rate, arc voltage, or weaving width. This constantly adapts the process to varying conditions, such as changes in the gap, alignment, root face, or temperature. The computer’s fast reaction time means the machine can work at high deposition rates and travel speeds at which weld pool conditions are too critical to be sustained by hand.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

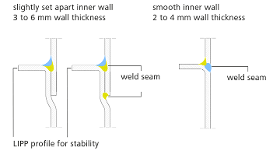

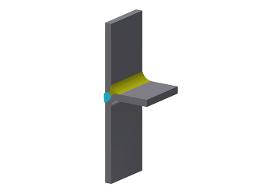

TECHNOLOGICAL INNOVATION OPENING UP NEW MARKETS The new automated Lipp welding process will again shake up tank construction market just as the well established Lipp double fold system did decades ago. It is a perfect combination of the long experience in metal forming and state of the art welding technology. KEY BENEFITS OF THE LIPP WELDING TECHNOLOGY Automated welding proces, on site Visual weld monitoring and technical documentation Reinforcement ribs for enhanced structural stability and reduced material costs High quality and repeatability Fast installation Choice of different material grades and types CERTIFICATES SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY BLACK STEEL SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY STAINLESS STEEL Beside black steel, various grades of stainless steel and duplex steel can be auto welded. In addition to the new potential markets and applications, the Lipp automated welding technology will increase the competitiveness

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The core of the technology is the automated welding process, where the tank is simultaneously welded on the inside and the outside. Similar to the Lipp double fold technology the material will be pre formed by Lipp special forming machines and reinforcement ribs are applied for additional stability. By doing so, the wall thickness can be reduced which will have an economic effect on the overall material costs, without compromising structural stability. The process also enables the installation of roofs and other accessories at ground level, which reduces the risk of working at heights. The main application for the new Lipp welding technology is the drinking water sector. However, there is lots of market potential in the food and beverage industry, chemicals and pharmaceuticals as well as other industries. The black steel welding technology enables the installation of bulk silos with huge diameters and volumes, which is a significant improvement compared to today.

Request for a quote

PIERON GMBH

Germany

Dimensions Depending on the required stamp power (material strength, material thickness, and part shape) Material All spring materials in soft and hard condition as well as quality steels with lower strengths and aluminum alloy and also special alloy Stainless steel up to 1900 N/m² Rubber-coated strip material Hardening Through external services Coating Fully or partly coated strip material In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Fully automated manufacturing of components and mounting Fully automated welding Contact springs with contact rivet Bushes clinched, welded, and open Special processing like thread cutting, screw mounting, and rivets feasible Special packaging in blister pack, trays or magazines Rapid prototyping

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The LIPP® Large Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The largevolume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. Speciality No additional nitrogen system necessary.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Whether for manual welding in steel construction with 15-18 kg spools or for semi-automated and fully automated welding with drums of up to 750 kg wire weight, WDI has the right drum in its range for every application. Container types for unalloyed and medium-alloyed shielding gas welding wires

Request for a quoteResults for

Automated welding - Import exportNumber of results

86 ProductsCountries

Company type

Category

- Tanks, metal (30)

- Wires and cables, steel (16)

- Laser - cutting and welding machines (7)

- Textiles - Machines & Equipment (6)

- Welding, electric - equipment and supplies (5)

- Autogenous welding machines (3)

- Steels and metals - welding and brazing (3)

- Welding work - steels and metal (3)

- Storage tanks (2)

- Automation - systems and equipment (1)

- Concrete mixers (1)

- Industrial equipment hire (1)

- Pipes, bent - ferrous metal (1)

- Sensors (1)

- Stainless steels (1)

- Steel & Metals (1)

- Welding robots (1)

- Welding, soldering and brazing - equipment and supplies (1)