- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- working process

Results for

Working process - Import export

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

An efficiently sharpened saw blade is essential for productive and safe work processes. Tyrolit offers an extensive range of grinding tools for various saw blades, including chain saws, circular saws, band saws, and gang saws. Our abrasives are precisely matched to different grinding machines and tooth pitches for optimal sharpening results, featuring vitrified-bonded grinding wheels and resin-bonded diamond and CBN wheels for special applications. Tyrolit’s decades of experience are evident in our tools' grit qualities and innovative bond systems, ensuring optimal cutting edge quality. Our grinding tools for automatic chain saw sharpening machines promise extended service life and perfect tooth base radius matching. We also offer resin-bonded diamond wheels for special applications and CBN tools for grinding HSS and high-alloyed steels.

Request for a quote

PENGG KABEL GMBH

Austria

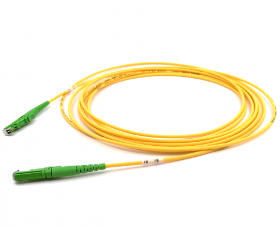

Our pigtails and patchcables are manufactured completely according to customer specifications in terms of connector-, cable- and fiber type, quality class, length and color – we can respond to our customers’ wishes accordingly flexibly. All the steps of the connector assembly – from the plug assembly to quality control – are carried out by our highly qualified embloyees under optimal working conditions. Our assembly process consists of several steps, such as exposing the fiber, gluing the fiber in the ferrule and curing. After curing, the connector ferrules are polished in several steps, giving them the final shape and surface finish. The finished connectors then go through our 100% quality control. Each connector gets testet at the insertion and return loss measuring station, as well as the geometric surface quality is measured and documented using an interferometer.

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

starlim//sterner's work is process-related, thus eliminating sources of error wherever possible. The zero fault philosophy is a clear commitment to our customers and guides all starlim//sterner workers who process their daily tasks. Fault-avoiding approaches such as FMEA, advanced quality planning (APQP), consistent monitoring of production processes and stable processes with high CPK ratings currently result in a failure rate of < 1 ppm. We envisage a further improvement of the ppm rate by continuously introducing improvements. Certified management systems make sure that the zero-fault philosophy is realized throughout the group's entire organization. We will not rest on our laurels, but work continuously on the improvement of our products, our services and our performance. If you want to send us commentaries, complaints or simply a few encouraging words, send them to this e-mail address: customer-service[at]starlim-sterner[dot]com.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Working process - Import exportNumber of results

3 ProductsCompany type