- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal casting

Results for

Metal casting - Import export

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

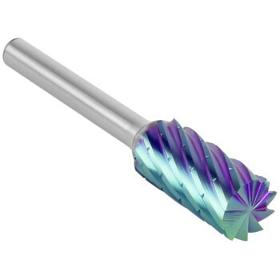

Tyrolit’s tungsten carbide burrs can machine materials like steel, stainless steel, non-ferrous metals, cast iron, and HSS. They come in various shapes and profiles, including tapered, cylindrical, ball-shaped, and special designs for angles, corners, and flutes. The parts are soldered with a copper alloy for impact resistance, enhancing safety and performance. Our burrs ensure first-class grinding with maximum economy, featuring long tool life due to a specially developed cutting edge geometry. The aggressive cutter profile allows for significant material removal in a short time, with reduced heat generation to protect both tool and workpiece, crucial for stainless steel to prevent discoloration. The new HPC-coated tungsten carbide burrs for cast iron, steel, and stainless steel offer higher performance, longer life, and better results. The advanced coating improves chip transport and doubles stock removal, with a distinctive Tyrolit color combination.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

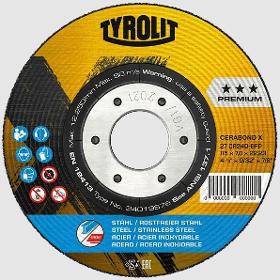

Tyrolit's rough grinding wheels meet advanced economic requirements with high stock removal rates, ease of handling, and long life. Our innovative wheels ensure optimal results in both standard and special applications. In steel working, demands for better standing times, higher stock removal, and shorter machining are crucial. The CERABOND X range, with high-grade ceramic grain and innovative bond structure, meets these challenges, excelling on hard steel types and large diameters for economical processes and excellent results. Enhanced Safety and Comfort VIBSTAR reduces vibration by up to 50%, counteracting occupational diseases. SILENTIO reduces noise by 10 decibels, preventing physical damage and increasing comfort. "Comfort Start" technology ensures optimal performance from the start. High-Quality Grinding Wheels Tyrolit’s 1F80 range for straight grinders offers low-vibration work with high stock removal rates on steel, stainless steel, nonferrous metals, and cast iron.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers product solutions for materials such as steel, stainless steel, nonferrous metals, grey and spheroidal cast iron, construction materials, and stone. We provide cut-off wheels, diamond saw blades, and machines for the construction and metalworking industries. Our cut-off wheels for steel, stainless steel, nonferrous metals, stone, cast iron, and construction materials offer top-notch properties. Designed specifically for steel and stainless steel, these thin and fine-grained wheels enable short cutting times and fatigue-free work, ensuring long life and preventing material damage. Our cut-off wheels for ring saws and cut-off machines deliver excellent performance and durability. We offer diamond saw blades and resin-bonded cut-off wheels in diameters of 300, 350, and 400 mm for petrol and electric machines. Hand-held ring saws are equipped with diamond tools ranging from 300 to 500 mm in diameter.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

During pendulum grinding, the Tyrolit grinding wheel moves over the workpiece at a high feed rate. The cast material is processed during the stroke movements, both in synchronised and counter-rotation. Tyrolit pendulum discs are suitable for almost all pendulum grinding machines and deliver the best results, for example when grinding and fettling heavy cast workpieces or metal blocks. The high-quality Tyrolit grinding discs for pendulum grinding are the result of decades of expertise in the development of grinding tools. They significantly increase the efficiency of manual machining of cast workpieces. Zirconium aluminium oxide is frequently used in the abrasive mixtures, which enables shorter grinding times, higher stock removal rates and longer tool life. Advantages of Tyrolit grinding discs: . Less effort required due to high cutting ability . Customised product . Maximum safety for manual sanding work

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

External cylindrical grinding is essential for achieving optimum surface finishes on workpieces like camshafts, crankshafts, and transmission shafts. It's used on various materials, including unalloyed, low-alloyed, and high-alloyed steels, HSS, tungsten carbide, industrial ceramics, and cast metals. The key to selecting the right tool lies in matching the grinding wheel to the specific requirements of the grinding application. This involves considering workpiece properties, tool, machine, settings, cooling lubricant, and dressing technology. Our high-quality tools and consulting services ensure optimal process parameters. Tyrolit offers a wide range of high-quality grinding tools for various applications and materials. We provide vitrified-bonded conventional wheels with different grains for specific materials, and resin-bonded high-performance tools made of CBN or diamond with our special bond system. The VIB STAR system reduces vibration for a smooth grinding process.

Request for a quote

PLANSEE SE

Austria

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. Here, the mold has to repeatedly withstand the metal melt at a temperature of over 600 °C: for inserts made of our tungsten-heavy metal alloy Densimet® and the molybdenum alloy TZM, that's not a problem. The benefits to you: — Shorter cycle times — Top surface quality for your products — Long mold service life — No cracks in the mold insert Tailor-made mold inserts, sprue bushes, cooling inserts and other individual parts as well as semi-finished products for your mold are available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Metal casting - Import exportNumber of results

6 ProductsCountries

Company type