- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas cooling

Results for

Gas cooling - Import export

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Biogas, sewage gas and landfill gas contains not only water vapour but also a whole host of additional impurities such as hydrogen sulphide, NH3 and siloxane, which, when processed in the utilization system can not only lead to a reduction in efficiency, but also result in damage to the system. The dehumidification of the gas before processing is a basic preliminary requirement in order to permit an efficient usage of the biogas and an investment in the sustainability of the utilization system. With the ennox gas chill dryer the gas to be processed is passed through a heat exchanger where the cooled gas can expel any moisture which drips and is collected as condensate. According to the technical requirements of the installation a post-warming or an economical and ecological energy recovery system can be implemented into the system.

CTP CHEMISCH THERMISCHE PROZESSTECHNIK GMBH

Austria

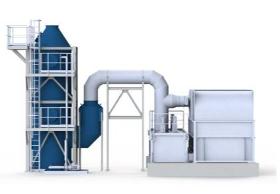

CTP's wetabsorber: After the oxidation of for example halogenated hydrocarbons, the corresponding hydrogen halides and elemental halogens emerge. Inorganic pollutants are efficiently removed from the waste gas by wet gas purification. The combination of exhaust gas cooling (quench) and waste gas purification (scrubber) is ideal for use after a convential APC system. Maximum cleaning efficiency High safety standard High availability Low maintenance costs

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

The welding torches are designed for use on robots for high-performance welding under harsh conditions. The slim design, together with the swan’s neck shape, permits the best accessibility even in narrow parts of the work piece. All welding torches provided as standard for igm robots have a particularly stable design with intensive water cooling and a quick-release coupling. They are also configured for pneumatic torch cleaning with compressed air at least 7 bar and for the use of the gas nozzle as a tactile sensor for program shifts. The arrangement of the contact tube in connection with the torch curvature ensures the forced contact of the welding wire. This ensures a uniform and constant current transition to the wire electrode under all conditions and wear conditions. Direct water cooling of the gas nozzle reduces the adhesion of weld spatter. The cooling water is routed through its own channels in the torch body up to the contact pipe, and from there through the nozzle stock...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Gas cooling - Import exportNumber of results

3 ProductsCountries

Company type