- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- auger fillers

Results for

Auger fillers - Import export

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 55 was developed to meet the demand for high throughput rates. Flexibility, easy maintenance, simple settings, synchronisation with the infeed systems, flexibility and quiet operation were the priorities in the development of this machine. The machine achieves an output of up to 80 bags / minute. The most common options and accessories: - Hanger hole - Precutter for easy opening - Jogger to level the products before closing the bag - Bag identification system: - Marking by transfer to the film - Label printer - Inkjet printer - Flap for heavy products - Cell for pre-printed film - Drive by suction belts - Synchronisation with: - Multihead weigher - Auger filler - Cup doser - All other machines - Suction plate for changing the film roll

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is Controlled with fast and accurate servo driven specific auger (worm screw). The auger type and diameter changes with respect to product type and target weight. All surfaces touching to products are AISI 304 stainless steel. Easy dismountable collar set design. Package length should be controlled by print mark or feeding duration. Printer state is checked continiously. Wrapping material is driven by AC motors. Pneumatic driven horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. Suitable for CE standarts.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlledwith fast and accurate servo driven specific auger (wormscrew). The auger type and diameter changes with respect to product type and target weight. · All surfaces touching to products are AISI 304 stainless steel. · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. Printer state is checked continously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. · Impulse or heat sealing units for different type of wrapping materials. Wrapping material tension is controlled continously. · Autamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

HARKOM MAKINA SAN. TIC. LTD. ŞTI

Turkey

The machine is designed for powder and similar fine products. The target weight of each filling is controlled with fast and accurate servo driven specific auger (worm screw). The auger type and diameter Changes with respect to product type and target weight. All surfaces touching to products are AISI 304 stainless steel. · Sutiable for quadseal packages · Easy dismountable collar set design. · Package length should be controlled by print mark or feeding duration. · Printer state is checked continiously. · Wrapping material is feed by Servo motors. · Servo Motor Controlled Horizontal sealing and cutting. Impulse or heat sealing units for different type of wrapping materials. · Wrapping material tension is controlled continiously. · Auotamic lateral adjustment of wrappin material. · Suitable for CE standarts. · 7 inch touch screen wtih several languages.

Request for a quote

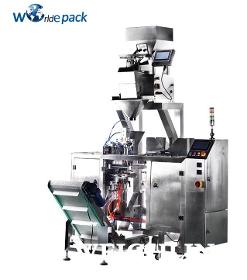

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Equipped high-quality performance various weight filler and mini doypack machine with auto ziplock opener and output conveyor, date printer as an option for solid granules, powder, liquid, paste, etc. Apply for different premade pouch types, such as Custom Packaging Styles flat Bottomed Pouch, Stand Up Pouch, Quad Seal Bag, Flat Pouch – 3 Side Seal Bag, Shaped Pouch, Retort Pouch, Kraft Paper Bags. Bulk material feeding conveyor as an option available Various weight fillers such as auger filler, multi-head, linear, pump filler, etc. Supporting stand Mini Doypack Machine Output conveyor Metal detector and weight checker as option

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.The machine use premade pouch,you have more choice for the bag type and excellent appearance . 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.The main configuration is Siemens PLC control system,simple operation, and easy maintenance. 4.The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch. 5.Easy to link up with other packaging equipment such as multi-heads weigher, liquid pump filler, auger/agitator fillers, feeding conveyor,platform,the cartoning machine,case sealer etc. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary pouch bagging vacuum packaging machine combine with different fillers,such as weighing machine,liquid pump and auger/agitator fillers, accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling,vacuuming,sealing,and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials.Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids. 3.Adopt Siemens PLC control system, be easily performed operation and maintenance. 4.Filling machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable smooth running, it means high performance and high durability.All grippers width of filling machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust.

BASIS, LLC

Ukraine

"Cartoner Basis40 is a step-by-step model that provides high quality packs at speeds of up to 40 packs / min. In the basic configuration, the cartoner demonstrates the ideal price-performance ratio. A variety of modifications of the Basis40 cartoner gives you an ability to pack a wide range of products in cardboard packs of various shapes. provides the possibility of products packing in a wide range of packs of various forms (optional) can be equipped with various types of weighers: combinational (multihead type); linear; volumetric; auger filler. manual feeding is possible; gives you ability to pack different types of products: bulk; dusty; lump; simple and reliable construction provides minimal operating costs; high-quality components ensure reliability and durability of components and mechanisms; Glueing is controlled electronically; Cartoner is made in accordance with the requirements of current sanitary norms and regulations as well as the requirements of the CE standard.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing: - 100% tare/gross weighing - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Shapes: - User-friendly, fast and primarily tool-free format change Design: - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - Volumetric dosing with auger filler - High-precision positioning for constant filling weight/volume Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Volumetric dosing with auger filler Design: - Can be designed as a monobloc combination with filling and sealing modules - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Products in contact with metal parts made of stain steel and/or food-grade plastic - Secure and sturdy mechanical system - Standard version with 1 working station - Standard version with up to 2 working stations - Few moving parts resulting in minimized sealing and maintenance costs

OPTIMA CONSUMER GMBH

Germany

Pull-out of processing modules to perfection: - Easy accessibility - Reduced cleaning and maintenance time Increased lane distance: - Processing of large-volume capsule portion packs Equipped with auger filler OPTIMA SD1: - Integrated weighing with mean value regulation and selectable compaction Handling modules: - For example to place plastic filters Integrated punch and seal module: - Suitable for processing of metal-free film Filling of ground coffee, tea or instant products

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-40

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-5

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Filling station on the module trolley for a quick change and separate cleaning - Hot filling possible - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available - Volumetric dosing with auger filler

OPTIMA CONSUMER GMBH

Germany

Filling: - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product - Synchronization interface for the bottling plant - Vibrating the containers under the filling positions for product compaction and optimal utilization of the container's volume Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-fc2

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Auger fillers - Import exportNumber of results

18 ProductsCountries

Company type