- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aspirating systems

Results for

Aspirating systems - Import export

ROBINSON CO.

Turkey

It is generally used as a dust collector, dust and air separator for the product. It is found in aspiration systems of cleaning machines. Dust removed by aspiration is separated from the air by means of a cyclone. The dust-laden carrier air is directed inside the separator thanks to the helical construction and is forced to rotate in the cyclone. Dust particles are dispersed to the environment with the effect of centrifugal forces arising due to rotation. Dust particles are carried along a helix path by means of the vortex created by the air pushed from behind. The clean air separated from the dusts goes through the suction pipe and goes to the outlet. Dust particles are directed downwards along the spiral due to the friction of the air against the wall. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Counterflow cooler is utilized for cooling the feed that comes out from pellet mill in pellet form which is hot, to ambient temperature. It works according to steady air form principle. Air in the external environment contacts the feed in the cooler; while the temperature of the feed drops, warm air is removed from the environment through air aspiration system.Discharge system which is on the cooler, removes cooled feed. Drainage system can be chosen with grid or hydraulic valve depending on the preferred product. Drainage system is adjustable and works according to the capacity. Applications Fields ◾ Feed Plants

Request for a quote

VERCO ELECTRO COMPONENTS

Belgium

Les extracteurs de particules métalliques Pulsotronic se présentent sous la forme d'un coffret de 450x450 mm. L’extracteur s’intègre directement sur le système d’alimentation par aspiration (air pulsé). Sa conception le rend indépendant des variations de vitesse, de débit, de densité et de taille du matériau. L'étanchéité de l´ensemble est conservée durant l'évacuation du matériau pollué par du métal. Diamètre de passage: de 38 à 70 mm Sensibilité: à partir de 0.3 mm en Fe Existe en versions: MESEP, DIGITAL+, M-PULSE Débit maximum: 3300 l/h Autres systèmes de détection de particules métalliques: Détecteurs plats pour installation sous ou au dessus des bandes transporteuses Tunnels de détection sur convoyeurs Détecteurs annulaires Séparateurs Réalisations spéciales Pulsotronic fabrique: Capteurs inductifs et capacitifs Appareils et lignes pour la détection et la séparation de métaux Systèmes de traitement d´images Capteurs magnétorésistifs Capteurs optoélectroniques et systèmes...

Request for a quote

APD MAQMASTER

Spain

X axis (Longitudinal) 2000 mm Y axis (Horizontal) LEPUS II 4000 mm – LEPUS II L 7000 mm Z axis (Vertical) – without milling 200 mm POSITIONING DISTANCES X axis (Longitudinal) 55 m /dK Y axis (Horizontal) 55 m /dK Z axis (Vertical) 15 m /dK SPINDLE Spindle cooled by 4 fans Maximum power 2.2 kW Maximum rotation speed 18000 rpm ER20 tool holder CONTROL UNIT CNC control Remote network connection, data transfer via Ethernet and USB. OPERATIONAL AREA Dust and chip aspiration system Suction areas in independent spaces Externally controlled vacuum tables LAPUS II 6 – LAPUS II L 8 Automatic tool length measurement Possibility of doing double station processing X axis reference support Y axis reference support LEPUS II 4 – LEPUS II L 9 Metal fences closed on three sides that prevent access to the work area

Request for a quote

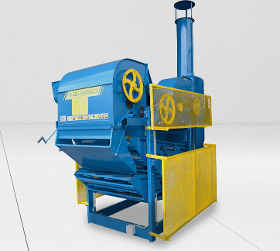

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The supersonic filter is used for the separation of air-dust mixtures coming from the aspiration system as well as pneumatic conveying systems. The air-dust mixture enters the machine and the dust remains on the filter bags. These filter bags are shaken out using pressurized air by the diaphragm system and the dust is collected at the bottom of the filter. For the removal of the dust collected at the bottom of the machine, a sweeper can be used as well as a conical bottom with a rotoflow.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-50 is a mobile high-performance hybrid of a grain cleaning machine and a grain loader. OBC-50 can be equipped with a receiving funnel with a capacity of 2 tons of grain and a cyclone. Mobile grain cleaner OBC-50 provides grain cleaning from fine impurities on sieves and from light impurities using the built-in aspiration system. The capacity of the aspiration system in the OBC-50 is regulated depending on the type of grain being cleaned and its degree of contamination. The aspiration system can be removed and then the OBC-50 turns into a grain loader with the possibility of separating fine impurities on the sieves. Mobile grain cleaner OBC-50 produces: cleaning grain heaps of cereals, legumes, ears, cereals, sunflower, corn, soybeans, sorghum; loading grain into vehicles with a side height of up to 2 m; mechanical shoveling with simultaneous cleaning and partial drying of grain in open areas and in grain stores.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-25CE is a stationary grain cleaning machine equipped with unloading elevator additionally. Presence of such kind of elevator simplifies grain cleaning process and makes it possible transferring grain into vehicles, grain vessels, trailers, big bag etc. Machine can also be equipped with a boot elevator and cyclone if necessary. On customer request wheels can be installed to OBC-25CE that turns the unit into mobile one. OBC-25CE performs grain and seeds cleaning using an aspiration system and sieves. Spreader separates impure grain in two equal parts and directs it to air channels. Fan airflow takes light impurities out. Larger impurities are captured with settling chamber from air stream. After that grain purified in aspiration system comes to upper and lower sieves. At these sieves grain gets cleared of impurities kind of different size. Pure grain is collected at the bottom of OBC-25CE and unloaded with built-in elevator.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Stationary grain cleaner OBC-25S performs cleaning of cereals, legumes, sunflower, sorghum, rapeseed, corn, etc. Grain cleaner OBC-25S is installed in existing grain cleaning units or mounted separately. OBC-25S is equipped with a receiving chamber, an air-cleaning part, sieves, a feed waste screw. All working bodies are mounted on the frame. OBC-25S performs cleaning of grain and seeds using an aspiration system and sieves. The distributor divides the grain with impurities into two equal parts and directs it to the air channels. Airflow through the fan carries off light impurities. Larger impurities from the air stream are captured by the settling chamber. Further, the grain purified by the aspiration system falls on the upper and lower sieves. On sieves, the process of cleaning grain from impurities that differ from grain in size occurs. The sieves are cleaned with brushes. If necessary, OBC-25S can be additionally equipped with loading and unloading elevators, as well as a cyclone.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The mobile grain cleaner OBC-355CMA with a cyclone and a loading auger is designed for cleaning and calibrating any grain and preparing high-quality seed material. It is an innovative combination of 5 sieves installed in a drum with adjustable rotation speed and angle of inclination, an adjustable powerful aspiration system, a large number of overhead valves and augers. The mobile grain cleaner OBC-355CMA has enormous possibilities and more than 50 applications ranging from preliminary cleaning of grain to high-precision calibration of grain at once from 3 different types of plants for seeds. Mobile grain cleaning machine OBC-355CMA is easily transported by minibus, small truck or tractor on the road. This is the best solution for farms with several grain warehouses, as well as for businessmen providing grain cleaning services. Take full advantage of this mobile grain cleaner and take your business to the next level.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The OBC-25SC grain cleaner cleans any grain using 8 sieves and an aspiration system with a built-in cyclone. The installation of a cyclone at OBC-25SC made it possible to solve the problem of cleaning the air emitted by the OBC-25SC fan from dust and light impurities (small parts of leaves, grains, insects, sand, etc.). Previously, this was solved by installing a separate cyclone near the OBC-25S, conducting an air duct from the OBC-25S fan to it, and installing a clean air exhaust system from the cyclone. This led to significant additional costs and required a large free space. Now OBC-25SC with an integrated cyclone that successfully copes with cleaning a heap of grain, saves space and money. Additional advantages of the grain cleaning machine OBC-25SC: - high productivity with small sizes; - simple, durable design; - quick sieve change; - automatic cleaning of sieves with built-in brushes; - can be equipped with lifts, cyclone pipe and wheels.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

ОВС-70L is a self-propelled high-performance hybrid of a grain cleaning machine and a grain loader. The main difference between ОВС-70L and ОВС-70M4 is that the ОВС-70L has an elongated unloading elevator, but there is no trimmer and sieves. Cleaning grain of any humidity or contamination is carried out using an aspiration system and a mesh conveyor. For better grain cleaning, a self-propelled grain cleaner OBC-70M4L is used. At ОВС-70L, the cleaned grain is not conveyed by the conveyor to the trimmer, but directly to the trailer, big-bag, hopper, or poured down. Functions performed by the self-propelled grain cleaner ОВС-70L: - cleaning grain heaps of legumes, grains, cereals, corn, sunflower, rapeseed, sorghum, etc .; - loading grain directly into vehicles with a side height of up to 3 m; - loading grain into big bags, bags, bins, loader buckets, etc.; - mechanical shoveling of grain, accompanied by its simultaneous cleaning, as well as partial drying in open areas or granaries.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain cleaning complex OBC-70M4 is an ideal solution for cleaning, drying and loading grain any kind of transport. High cleaning quality is ensured by the use of a built-in mesh conveyor, sieves and a powerful adjustable air aspiration system. OBC-70M4 moves independently and cleans and loads grain without the help of other machines and people. This grain cleaner has a capacity of 80 tons per hour for all major crops. At the same time, energy consumption is only 0.25 kW / h for processing 1 ton of grain. The height of storage and loading of grain is up to 10 meters, the flight range of grain is up to 25 meters. Self-propelled grain cleaning complex OBC-70M4 has triple control - automatic, manual and remote. The design of this grain and seed cleaning equipment is as safe and convenient as possible. Anyone can work on OBC-70M4 after instruction, because it is very easy to operate this grain cleaning equipment.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quote

SILOS SPAIN INSTALACIONES, S.L.

Spain

Efficient post-harvest handling of rice ensures food security. Keep rice clean, dry, and undamaged during storage. Factors to consider: -Moisture content: Aim for ≈ 25% at harvest. -Temperature: High temps promote fungi growth and oxidation. -Storage period: Shorter is better; clean grain before storage. -General condition: Check for broken seeds, impurities, and more. Post-harvest processes include reception, cleaning, drying, and storage. To maintain quality: -Reception: Analyze heat, moisture, and impurities. Use insect control measures and an aspiration system. -Cleaning: Install an integrated system with a magnet separator, drum sieve, grain precleaner, grain cleaner, and buffer silos. Ventilation and exhaust fans are crucial. -Drying: Reduce moisture to safe levels. Prevent discoloration, loss of germination, freshness, and breakage. -Storage: Popular options are steel silos, concrete silos, warehouses, and bag silos. Optimize storage with proper management.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to divert the product both for pressurized conveying and for aspirated pneumatic conveying systems

Request for a quote

AFRIMEX BELGIUM

Belgium

Technical Engine 4.200 cc 6 cyl. diesel 131 HP Manual gearbox 5 gears 4x4 Fuel capacity 90 + 90 L Tropical specifications Interior Fabric seats 3 places Separated air-conditioner Airbags Radio CD Exterior 2 Side doors + 2 back doors Tires 7.5 R 16 Snorkel/tuba Side steps Flash light bar Siren Ambulance equipment Separated ambulance compartment Lightning system rear Closet Aspiration devise Humidifier and oxygen debit meter Mobile stretcher ‘Roll-in’ bed First aid bank Closet department for medical tools First aid kit Ventilation system rear Fire extinguisher

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAMA AERNOVA SRL

Italy

Data sheet Product Thanks to their reduced dimensions, ease of use and functioning efficiency, EXPLORER filters represent the real solution to the problems of aspiration and filtration of fumes deriving from different industrial productions. This model of filter has been designed according to the principles of modern technology and it's addressed to those industrial and handcrafted applications that need an aspiration and filtration system that proves to be easy to install, of reduced dimensions but of great manageability and stability; specifically, it's been developed for field as industrial mechanics and industrial furnaces where oily refrigerating liquids are used. The EXPLORER filters are made of modular panels, varnished with powder paint. They are equipped with coupling flange that allows its installation on the machine and fan with command and lighted control. They are available in the electrostatic version with one or two cells (tandem model) or in the mechanical...

Request for a quote

TAMA AERNOVA SRL

Italy

Data sheet Product Thanks to their reduced dimensions, ease of use and functioning efficiency, the ANTARES 100 filters represent the real solution to the problems of aspiration and filtration of fumes deriving from different industrial productions. This model of filter has been designed according to the principles of modern technology and it's addressed to those industrial and handcrafted applications that need an aspiration and filtration system that proves to be easy to install, of reduced dimensions but of great manageability and stability; specifically, it's been developed for field as industrial mechanics and industrial furnaces where oily refrigerating liquids are used. The ANTARES 100 filters are made of modular panels, varnished with powder paint. They are equipped with coupling flange that allows its installation on the machine and fan with command and lighted control. They are available in the electrostatic version with one or two cells (tandem model) or in the...

Request for a quoteResults for

Aspirating systems - Import exportNumber of results

20 ProductsCategory

- Agriculture - Machines & Equipment (8)

- Flour milling - machinery and equipment (3)

- Ambulance transports (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Medicine and surgery - apparatus and equipment (1)

- Milling - machine tools (1)

- Pneumatic conveyor equipment (1)

- Silos, metal (1)