- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- asphalt and tar for roads

Results for

Asphalt and tar for roads - Import export

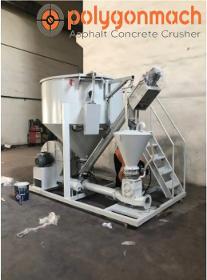

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The MCA 100-120 tph Continuous Asphalt Plant is the technology pioneer in asphalt production, offering best-in-class efficiency and performance for medium to high-volume projects. This continuous asphalt plant is durable and fully equipped with advanced characteristics that enable quality continuous asphalt mixture production. It offers a range of production capacities from 100 to 120 tons per hour, which deals with a wide variety of road construction applications. This plant is designed for the production of asphalt for any requirements with the ultimate accuracy and consistency of results. The power-packed MCA 100-120 tph plant, standing out to be the strongest of its kind in construction and ultra-modern technology, is suitable for all projects from highways to luxuriant urban roads and on to industrial zones. It can produce numerous sorts of asphalt mixtures, including those needed for base, binder, and surface courses.

Request for a quote

BITUMER SP. Z O.O.

Poland

Bitumer TIXO is one-component, plastic, ready-to-use bituminous mass highly modified with synthetic rubber. Product is a modified bitumen reinforced with additives. High solid content gives possibility of making a good lasting bond which secures and seals the connection of asphalt materials. Solvent content gives a possibility to apply material without heating by cold applied method with spatula or mechanic way. •sealing joints in asphalt roads •sealing of concrete-metal joints •sealing penetrations through building structures •for repairing damage and filling defects in roofing (kinks, cracks, crevices, blisters, leaks), •local waterproofing sealing, flexible seamless waterproofing coatings underground, •for expansion joints between working elements of concrete and steel structures

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The MCA 140-160 tph Continuous Type Asphalt Plant represents the latest technology in asphalt producing plants, especially engineered to provide extra capacity and efficiency for medium-to-high-volume projects. In these advanced plants, high-quality asphalt mixes are produced with uniformity—the challenging requirements expected of road construction. It has a production capacity ranging from 140 to 160 tons per hour, hence making this a versatile and reliable solution for many various applications. The design is user-friendly in the sense that one gets precision, performance, and durability, thus making this an ideal choice for use in different construction needs. The MCA 140-160 tph plant is designed to fit demanding requirements by advanced technology with sturdy construction. Such machines are outstanding in asphalt production, offering quality for all jobs and reliability in functioning.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The MCA 120-140 tph Continuous Type Asphalt Plant has truly made a mark as world class in asphalt production technology, keeping in view the exacting requirements of medium to large projects. This superior plant has the capability to deliver quality asphalt mixes consistently in conformation with the stringent quality specifications stipulated for road construction jobs. This producing capacity, falling in the 120 to 140 tons per hour bracket, applies in various implementations, thus making it trustworthy and efficient for any asphalt production needs. The MCA 120-140 tph plant is the perfect blend of admirable performance and ease of use in one package. In its user-friendly design, advanced features, and rugged construction make it a trouble-free product to handle the most difficult conditions. This is more than just capacity—delivering better results with each batch so that all your road construction projects will be carried out with the best-in-class quality and efficiency.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Polygonmach MCA 60-80 Tph Continuous Type Asphalt Plant is designed for medium-sized projects requiring the production of high-quality asphalt. It distinguishes itself with an outstanding capacity-efficiency ratio blending in perfectly with both urban and rural road construction projects. Because of its emphasis on energy efficiency minimal environmental impact and operational flexibility this plant is a great option for projects involving tight space restrictions and environmental regulations. Its modular design makes transportation and installation easier greatly cutting down on the amount of time needed for project setup. This plant’s modular structure which guarantees fast assembly and disassembly and allows for easy mobility between sites was designed to meet the varied demands of different construction projects. Features to reduce dust emissions and energy consumption are included because environmental sustainability and operational efficiency are prioritized.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With an emphasis on quick deployment and simple operation for a prompt start of projects Polygonmachs 140–160 TPH mobile asphalt plant is painstakingly designed to offer a seamless user experience. Owing to its exceptional mobility it can be moved quickly and easily between locations. Operators can easily monitor and modify the asphalt production process by adjusting mix formulations and parameters to meet project requirements thanks to an intuitive control system. With flexibility ease of use and accuracy as its top priorities this plant can be used in a wide range of project environments The plant is very operator-friendly and its design ensures that even people with little experience can effectively oversee production. Because of the straightforward setup process and user-friendly controls that minimize downtime and boost productivity asphalt production can start almost immediately after arriving at any location.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

User Experience The Polygonmachs 120-140 TPH mobile asphalt plant is designed to provide an exceptional user experience. Its primary features are quick deployment and easy operation for a seamless project start. Because of its exceptional mobility site transitions can be ensured swiftly and seamlessly. The plants user-friendly control system makes it easy for operators to monitor and alter the asphalt production process. Due to the ability to optimize mix formulations and parameters to meet specific project requirements this ensures efficient production of asphalt under a range of conditions. Because of its flexibility the plant can also adjust to a range of conditions. This plant can be used for jobs that need it to be moved around a lot or set up fast in isolated locations. Its streamlined design and operational efficiency ensure that production can start almost instantly upon arrival at any site making it a flexible and reliable option for contractors.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Capacity of a Mobile Hot Mix Asphalt Plant Introducing the 60-80 TPH mobile asphalt plant from Polygonmach a state-of-the-art apparatus designed to satisfy the changing demands of contemporary asphalt manufacturing. This plant is a great option for medium-sized projects because it has great mobility high efficiency and outstanding quality output. Its adaptability allows it to be used in a range of construction scenarios and settings providing top performance no matter where it is used. This mobile plant is remarkable in that it can produce asphalt mixes that are dependable and consistent with a capacity range of 60 to 80 tons per hour. The plants cutting-edge technology guarantees that it can manage the demands of various applications while upholding the highest quality standards whether youre working on bigger infrastructure projects or fixing roads.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

You can embark on an efficient asphalt production journey into the future. Designed to transform the asphalt production process Polygonmachs PBA 240-320 TPH Stationary Asphalt Plant offers unparalleled quality and efficiency for major construction projects. High-volume asphalt projects benefit greatly from this state-of-the-art equipment because it guarantees optimal performance. We will examine the features parts assembly procedure and special benefits that distinguish the PBA 240-320 TPH Stationary Asphalt Plant from its rivals in this article. What is the PBA Stationary Asphalt Plant with 240-320 TPH Capability? This plant which can produce between 240 and 320 tons per hour ensures steady effective operation—a necessary quality for keeping up the pace of big projects. This facility is designed to withstand the rigorous specifications of building projects like building highways airports or industrial complexes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Twin Shaft Asphalt Mixer is, out of necessity, one of the main asphalt mixing machines designed for mixing aggregates with binders and additives for producing asphalt mixtures in road construction and infrastructure projects. A twin shaft asphalt mixer has two horizontally aligned shafts fitted with mixing arms, paddles, or blades rotating in opposite directions. This combination ensures that the input material will be well mixed and homogenized to produce high-quality asphalt mixtures consistently and reliably. What makes twin shaft mixers effective is the fact that they can process large volumes of materials without compromising mixing efficiency. They, therefore, hold a special place in industries in which uniform asphalt mix production becomes fast and efficient. Twin shaft mixers provide sturdy asphalt required for enduring infrastructural strains on highways, bridges, and urban roads.

Request for a quote

BITUMER SP. Z O.O.

Poland

Bitumer Flexigum N2 is a bitumen hot applied road sealant is produced from asphalt modified with SBS (Styrene-Butadiene-Styrene) polymers. The material retains high elasticity even at low temperatures down to -10 °C. The high quality of the base bitumen ensures resistance to UV radiation and a lower degree of filling degradation over time. USAGE •for use in structural and technological fillings: -expansion joints of asphalt concrete, -cement concrete, SMA mixes (Stone Mastic Asphalt), -in squares, streets, and car parks. •the compound is perfect for sealing joints between asphalt or concrete surfaces and steel elements (manholes), •works well as filling and sealing of damaged seams in asphalt pavements.

Request for a quote

BITUMER SP. Z O.O.

Poland

Bitumer Flexigum N1 is a bitumen hot applied road sealant is produced from asphalt modified with SBS (Styrene-Butadiene-Styrene) polymers. The material retains high elasticity even at low temperatures down to -10 °C. The high quality of the base bitumen ensures resistance to UV radiation and a lower degree of filling degradation over time. USAGE: •for use in structural and technological fillings: -expansion joints of asphalt concrete, -cement concrete, SMA mixes (Stone Mastic Asphalt), -in squares, streets, and car parks. •the compound is perfect for sealing joints between asphalt or concrete surfaces and steel elements (manholes), •works well as filling and sealing of damaged seams in asphalt pavements.

Request for a quote

BITUMER SP. Z O.O.

Poland

Bitumer Diplax is a special type of mineral and bituminous mixture used in the cold form. It can be used in all weather conditions at temperatures from -20 °C to +60 °C. It is prepared for immediate use directly from the package.It does not require the use of any specialized equipment. Damage repairs are waste-free and excess mix can be collected back into the container and used for another repair. Bitumer DIPLAX is used for: •express and permanent repair of damage to roads with asphalt and concrete surfaces. •for filling cavities after installation work: gas, plumbing, electrical, etc. •allows to eliminate damage of any shape, depth and size.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Envisioned to cater to small- to medium-sized projects Polygonmachs 40-60 TPH continuous type asphalt plant marks a noteworthy advancement in asphalt production technology. This plant efficiently produces high-quality asphalt mix by combining cutting-edge machinery and engineering. With a 40 to 60 tons per hour capacity it is notable for its productivity in a small package. Its modular design facilitates simple assembly and breakdown guaranteeing seamless transportation between locations. For construction companies that operate in several locations this makes it a priceless asset. Dust emissions and energy consumption are kept to a minimum by including features that promote environmental sustainability and operational efficiency in the plants design. The 40–60 TPH continuous type asphalt plant is well-suited for various construction projects due to its versatility and dependability.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

How much capacity does a hot mix mobile asphalt plant have? One of the best options for producing mobile asphalt is the Polygonmach 80–100 TPH mobile asphalt plant. To fulfill the demanding specifications of medium- to large-scale projects this plant combines exceptional quality flexibility and efficiency. Due to its maximum mobility it is ideal for contractors who need a dependable and flexible plant that can handle large production volumes and handle a range of project requirements. This plants capacity range of 80 to 100 tons per hour allows it to meet substantial demands for the production of asphalt. Because of its state-of-the-art technology and durable construction which are applicable to both major road projects and extensive infrastructure developments the plant is an excellent choice for high-demand scenarios. High output and the ability to maintain quality standards in a range of operating environments are both guaranteed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Extremely mobile and performance-driven the Polygonmach 40–60 TPH mobile asphalt plant is built to last. Offering both efficiency and flexibility this plant with a 40–60 tons per hour capacity is perfect for small to medium-sized projects. Due to its small size which makes it simple to transport and set up at different job sites it is the best choice for remote or temporary locations where space and logistics are limited. Because efficiency was the primary design consideration this plant is simple to operate and provides consistent asphalt quality. Operators can easily manage production thanks to the user-friendly control system which maximizes asphalt mix quality and output. A mobile asphalt plant with a capacity of 40–60 TPH can be used for a variety of tasks including both new highway construction and road repairs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A bitumen tank is a place where bituminous or asphalt binder is kept as a product in liquefied form. Basically, the name bitumen tank applies to any bitumen storage tank. Its main function is to store bitumen, and it is a very useful equipment for both the road construction and building industries. They guarantee established bitumen-keeping temperatures and prevent the product from hardening. Normally insulated and heated, bitumen tanks store the material under ideal conditions, ensuring its availability when combined with the aggregates in the production of asphalt mixes. The size of the tanks used depends on the requirements of the operation. When making such asphalt, larger tanks are found in asphalt production plants so that a continuous supply of bitumen is assured to the operations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Asphalt Fiber Granule Additive System is a modern, pre-engineered component assembled in asphalt plants for the introduction of fiber granules into asphalt mix with needed precision and control. These fiber granules play a vital role in strengthening asphalts against cracking, rutting, and other distresses. Fiber granules enhance the durability and performance of asphalt pavements, allowing them to sustain increasing volumes and intensities of traffic without being affected by various harsh weather conditions. The system is critical in the manufacture of high-quality asphalt mixes qualified enough for modern infrastructure. The effect of adding fiber granules into an asphalt mix is reinforcing; much the same way rebar does in concrete. This reinforcement allows such loads to distribute further out in the pavement, minimizing the chances of damage with time.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A hot asphalt storage silo is a specially designed structure used in the construction and road-paving industries to store hot asphalt mixtures prior to their application in various projects. These are parts of the asphaltic plants and paving operation; these are designed in such a way that stored asphalt should remain at a proper temperature to maintain workability features of asphalt up to the laying point. These silos provide a controlled environment that avoids cooling or solidifying too early in the asphalt, very essential to its usability during transportation and application. Primary function: These hot asphalt storage silos hold asphalt at a temperature of application on road surfaces and other infrastructure projects. Hot Asphalt Storage Silos are generally in the form of steel construction, insulated to retain heat

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

MCA 80-100 tph Continuous Type Asphalt Plant is a technologically advanced machine to produce asphalt mixes continuously in the medium to high category of volumes. As the name suggests, this plant has been designed with pinpoint accuracy and efficiency, merging state-of-the-art technology with strong, durable construction, to achieve continuous and uninterrupted production of consistent, high-quality hot-mix asphalt. It can produce between 80 to 100 tons per hour, adequate for many road construction projects. Compact design of the plant provides reliability and maximum performance, besides being user-friendly. Furthermore, it is versatile and cost effective for asphalt producers because it is splendidly modular in construction, with easy installation, transportation, and customization. This plant is designed for a wealth of applications in road construction.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Packed with state-of-the-art features the Polygonmach 140-160 TPH mobile asphalt plant promises to deliver superior performance longevity and environmental responsibility. The harmony between robustness and portability facilitates rapid and simple relocation guaranteeing adaptability in a variety of settings. The plants sturdy design guarantees that it can tolerate a variety of environmental factors and frequent relocations without sacrificing its high level of efficiency. The facility makes use of cutting-edge drying drum technology to effectively mix aggregates improving fuel economy and guaranteeing the creation of asphalt mixes of the highest caliber. Due to its ability to run on a variety of fuel types the plant is flexible enough to adjust to the demands of any given project maximizing environmental impact while raising operational efficiency. Modern emission control systems go above and beyond industry requirements demonstrating Polygonmachs dedication to sustainability.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

How much capacity does a hot mix mobile asphalt plant have? With its unique combination of exceptional efficiency flexibility and asphalt mix quality Polygonmachs 100-120 TPH mobile asphalt plant raises the bar for mobile asphalt production. This high-capacity plant offers unparalleled mobility and great performance making it ideal for medium- to large-scale projects. It is the best choice for a range of building needs and works well for tasks requiring the rapid production of high-quality asphalt. With a production capacity ranging from 100 to 120 tons per hour this mobile plant ensures that even the strictest asphalt needs are met. With its state-of-the-art technology and durable design the plant is a unique choice for high-demand scenarios guaranteeing consistent quality across a range of project environments be it a large highway project or significant infrastructure development.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Hot mix asphalt plants can be configured in a variety of ways to suit the needs of different projects. The main varieties are portable mobile and stationary plants each has a special benefit depending on the size and specifications of the building projects it supports. Because of their steady setup and high production capacity stationary plants—which are fixed at a single location—are perfect for big long-term projects. On the other hand plants that are mobile or portable provide flexibility and mobility enabling them to be quickly moved to various job sites. This makes them appropriate for smaller more dynamic projects or those that need frequent site changes. This adaptability is best demonstrated by Polygonmachs mobile or portable hot mix asphalt plant. These plants are lightweight portable and quickly assemble they require little work to assemble disassemble and move.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The pinnacle of productivity and innovation in asphalt manufacturing can be found in Polygonmachs PBA 320–400 TPH Stationary Asphalt Plant. Large-scale construction projects are the target market for this cutting-edge machinery which streamlines operations and maximizes the entire production process to deliver superior results. This page examines PBA 320-400 TPH Stationary Asphalt Plants key features assembly process specifications and unique selling points. One type of high-capacity equipment used to create high-quality asphalt for large construction projects is the PBA 320–400 TPH Stationary Asphalt Plant. The robust requirements of major infrastructure projects like highways airports and industrial sites are what this plant is designed to withstand. It can generate between 320 and 400 tons of asphalt per hour. Even the most ambitious projects will be successfully and on schedule thanks to the projects high production capacity.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Large-scale construction projects require asphalt of the highest caliber which is why the PBA 200-240 TPH Stationary Asphalt Plant has a high capacity. This plant which can produce between 200 and 240 tons per hour guarantees dependable efficient operation which is essential for maintaining the momentum of large-scale projects. This plant is built to withstand the rigorous requirements of construction projects be it highways airports or sizable industrial complexes. By carefully regulating the production process this plant excels in producing asphalt with exceptional quality. The PBA 200-240 TPH Stationary Asphalt Plant produces a product that is dependable and long-lasting by making sure that every batch satisfies stringent industry standards. In order to produce asphalt that can endure the rigors of heavy traffic and variable weather conditions assuring long-lasting performance and safety a high degree of precision and quality control is imperative.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

One of its key benefits is its amazing production capacity. The plant which can produce between 160 and 200 tons per hour ensures that construction teams can comply with quality standards and deadlines. With this high output you can precisely meet deadlines and maintain the projects progress. An additional significant advantage of the plant is the exceptional quality of asphalt it produces. Because of its precise control over the production process asphalt meets the highest industry standards. The end product is therefore of the greatest quality and remarkably durable prolonging the lifespan and usefulness of the constructed roads and structures. Because of its energy-efficient design the plant is a cost-effective and environmentally responsible option for construction projects.Given its emphasis on energy efficiency the plant is a desirable option for modern construction firms aligning with the growing demand for greener construction methods.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Discover the world of efficient asphalt production because of Polygonmachs PBA 120-140 TPH Stationary Asphalt Plant asphalt produced for large-scale construction projects will be produced differently. These cutting-edge instruments can optimize the asphalt production process which makes them an invaluable asset for large-scale construction projects. The PBA 120–140 TPH Stationary Asphalt Plant is covered in great detail in this article along with information on its assembly process and special features. What is the PBA 120-140 TPH Stationary Asphalt Plant like? We guarantee its dependable and effective operation. Because exact control is maintained throughout the entire production process every batch of asphalt produced by this plant is guaranteed to meet the highest industry standards. The PBA 120-140 TPH Stationary Asphalt Plant is perfect for highways and commercial buildings because it ensures the longevity and functionality of the built roads and structures.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

An asphalt vibrating screen is one of the most critical machines at asphalt-producing plants and in many construction locations. Its role is to filter and perform size classification of aggregates, thus ensuring conformance of materials used in asphalt mixtures to specified requirements. This screening process lies at the heart of producing quality asphalt that can perform and last in road construction projects. The vibrating screen efficiently sorts aggregates to ensure the right consistency and composition of the final asphalt mixture, which is an important requirement in a paved surface for strength and durability. Application of an asphalt vibrating screen does not just act in the role of material filtering, but rather, it directly affects the quality of the asphalt products realized. Without proper screening, uneven gradation may result in the product mixture, and this unevenness can result in weaknesses in the pave.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Large-scale construction projects require an asphalt production plant with a high capacity and the PBA 100-120 TPH Stationary Asphalt Plant is designed to meet those needs. This facility guarantees dependable high-efficiency operation with a production capacity of 100–120 tons of asphalt per hour. Because of its painstaking attention to detail every batch of asphalt is guaranteed to meet the highest industry standards ensuring the durability and functionality of the built roads and structures. This plant is designed to function extraordinarily well whether it is used on commercial structures or highways. The Polygonmach PBA 100-120 TPH Stationary Asphalt Plant has the power to completely change how asphalt is produced for large-scale building initiatives. This state-of-the-art equipment is an essential part of large-scale construction projects because it is made to maximize and streamline asphalt production.

Request for a quoteResults for

Asphalt and tar for roads - Import exportNumber of results

40 ProductsCountries

Company type