- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- articulated arm robots

Results for

Articulated arm robots - Import export

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

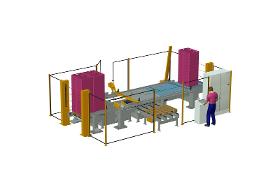

Advantages • Highly flexible palletizing solutions due to quick and easy re-configurations • Extremely precise operation ensures high quality palletizing • Use of a great variety of grippers makes for high flexibility • Coordinated concept including material flow environment Articulated Arm Robots offer highly flexible palletizing possibilities and are thus a real economical alternative. Especially profitable when with the corresponding performance two end packaging lines can be palletized by one machine. Articulated Arm Robots from Langhammer come delivered with the complete material flow environment in exact accordance with customer preferences. A turnkey installation from a single source.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Easy programming + maintenance via the PLC: no robot programming skills required • Optimal utilization of space + considerable space saving due to compact design • Highly flexible palletizing solution allows for any number of layer patterns • Layer weights of up to 200 kg possible • Gentle product handling of complete layers • Consistent and proven Langhammer operating concept allows for easy configuration In contrast to conventional systems with fork/clamp grippers, this compact design results in an enormous space saving of up to 40%. The new Articulated Arm Robot AR500 in combination with either Siemens or Rockwell controls guarantees easiest programming and maintenance directly via the PLC. By combining the Articulated Arm Robot AR500 with TheWave Langhammer offers a coordinated concept for the complete material flow, characterized by extreme accuracy & high-quality palletizing – and everything according to customer requirements – ready to go from a single source

STATEC BINDER GMBH

Austria

The high-performance robot palletizer PRINCIPAL-R, an articulated arm robot palletizing system, is always offered as a customer-specific solution with renowned industrial robot manufacturers and STATEC BINDER know-how. Depending on the required performance, different robot models are used. The gripper is also adapted to the respective application. A special feature of the PRINCIPAL-R is that it has been optimized for sling bags. As standard, jointed-arm robots with 4 axes and a rotation of up to 360° in the R-axis are used. This robot type is particularly suitable for palletizing and depalletizing applications due to its fast and repeatable movement. The operation and selection of the pallet patterns is carried out simply via a touch screen. The set-up variants range from a single to a double to a multiple line arrangement

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

With the robot wrist unit cartesian systems for the first time have the same flexibility and degrees of freedom as articulated arm robots. Only much cheaper and with much less space requirement. Moreover, IAI's unique design makes the components light and compact. Can also be used for an orthogonal axis system with interpolation function. The innovative wrist unit has two joints: The tilting joint for swivelling has a working circle of ±100⁰ while the rotary joint can be rotated around ±360⁰. The two pulse motors accelerate these cylinders at speeds of between 750 ⁰/s and 1,200 ⁰/s.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Economic + maintenance friendly articulated arm robot alternative • Flexible plastic case + carton tray stacking heights • Changeover times for gripper and format parts are eliminated due to automatic format changeovers • Unit performance can be expanded through additional stackers • Use of Euro pallets, Duesseldorfer half pallets + industrial pallets Within limited space situations the fully automatic stacking and palletizing unit is the first choice for flexible handling of all market formats. The slimly designed Stacker is economical + mainteance friendly when it comes to stacking plastic cases, meat crates, nestable carton and trays, mixed pallet commissioning or bakery baskets without pallets . Product and format changeovers are software controlled and require no tools. The Stack Palletizer is ideally suited for palletizing pre-stacked containers and the shuttle system allows for collecting different product stacks and creating mixed product pallet loads.

Do you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The critical process, as well as the parts for semiconductor device, which should be used in high temperature, vacuum and corrosive gas environment, require clean and dustless environment. However, precision ceramic material could maintain high stability in complicated physical and chemical environment. Semiconductor ceramic part we produced with wear resistance, corrosion resistance, low thermal expansion, insulation is made from 99.5% alumina ceramic and shaped by cold isostatic pressing, high temperature sintering and precision machining and polishing, can meet the stringent equirements of parts for semiconductor equipment. Selection of materials Selection of high-quality raw materials, good precision, strict quality control, longer service life Fine structure 20 Years of industry experience, a variety of molding processing technology and production equipment, fine workmanship, tight shape

Request for a quoteResults for

Articulated arm robots - Import exportNumber of results

7 ProductsCountries

Company type