- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- argon welding

Results for

Argon welding - Import export

BASAK LAZER

Turkey

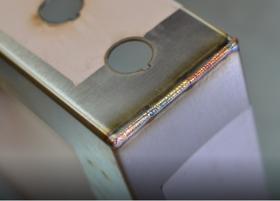

Argon welding is the word “Tungsten Inert Gas” that gives the welding method its name. Welding is also called the initials of this word and is referred to as TIG welding. The heat to perform the welding process is generated between the electrodes made of tungsten metal, which has a very high melting point, and the parts to be welded. The welding zone is protected by argon or helium gas sent from a nozzle surrounding the electrode. The electrodes used in the Tig (argon) welding method allow to join the welded material by melting, without melting themselves. When deemed necessary, additional welding rods are delivered to the welding area by the welder or by automatic wire feeding devices, as in oxy gas welding. Argon gas is generally used as a shield in argon welding. Argon gas is a noble gas, so it does not react and provides strong protection. It optimizes the ignition characteristics and stability of the arc

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Argon-arc welding Electric arc welding Gas metal arc welding Arc welding"

Request for a quote

BASAK LAZER

Turkey

In our factory, welded production can be made in line with the needs of our customers. We can prepare projects for our customers' production needs and produce them.

Request for a quote

PEMAT S.C.

Poland

Brand new gas Cylinder full of Argon 4.8 The cylinder is filled with a high quality 99,998% Argon welding compound. A protective cap protects the valve from damage during transport or storage. The cylinder is new and has a working pressure of 150 bar. The cylinder and valve are manufactured according to EN 1964:1999 and have the conformity mark π (pi) with the requirements of ADR / RID. ATTENTION! Our cylinders have a threaded valve (W21.8x1 / 14) and it is technically possible to fill it. However, filling problems can occur in certain countries such as France, Great Britain due to the type of valve used (G5/8") or Finland (W24,32x1/14) However, filling is possible without problem in most countries. TECHNICAL DATA CYLINDER GAS: Valve: 21.8 x 1/14 DIN 477 Content: 99.998% Argon Capacity: 8l Working pressure: 150 bar Quantity of gas: ~1.5m3 Height: 82 cm Diameter about: 14 cm Weight: ~13 kg Can be used throughout the European Union without additional testing for 10 years Powder coated according to current standards PN-EN

Request for a quote

BASAK LAZER

Turkey

We offer welded construction solutions using gas metal arc, argon, MIG, TIG and Laser welding technology according to the requirements of our customers. Welding is the process of joining two or more materials with the effect of heat and/or pressure, with or without the use of additional materials. In addition to the joining process, the welding process is used in coating and filling processes. Today, there are many different welding methods. It is a type of process that is used extensively in the industry. Welded manufacturing is defined as a special process in international standards. For this reason, there are international standards in order to guarantee and level the quality level in welded manufacturing.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ORBITEC GMBH

Germany

The pressure regulator can be tightened by hand without the need for a spanner. It reduces the stored bottle pressure from max. 200bar (on request 300bar) to an outlet pressure which is adjusted at the flowmeter. The flowmeters are used to set the required flow in l/min. Important: The pressure regulator has a constant outlet pressure of 2.5bar which is necessary to protect the gas flow sensor of the orbital unit. Versions: — Special Argon Pressure Regulator with twin flowmeter, brass — Special Pressure Regulator with twin flowmeter for H2-gases, brass — Special Argon Pressure Regulator with triple flowmeter, brass Pressure regulators with different connections and for use with other gas types or nickel-plated version available on request.

Request for a quote

TARET

Poland

We conduct welding processes in carbon dioxide and argon gas shields. We weld inox steel using the TIG method. We also weld aluminum alloys and non-ferrous metals. We perform spot welding on spot, table and forceps welders. We have about 10 welding machines in our machine park We have approximately 20 MIG-MAG and 5 TIG stations for welding. In our machine park we also have 3 welding robots from Yaskawa and one from ABB. Our largest robot has a working area of 6x2.5 meters.

Request for a quote

MR CO. LTD.

Ukraine

Argon welding is a popular name among people for welding technology, in which welding is performed in a shielding gas environment, most often argon. The gas prevents the metal under welding from coming into contact with the oxygen in the air, preventing oxidation. Inert argon is well suited for this purpose as it is non-toxic and relatively inexpensive. The equipment for argon welding comes in two types, TIG and MIG. In both cases, the machines are equipped with a non-consumable tungsten electrode. The difference is that TIG uses separate hard facing rods, but in MIG, the wire is fed automatically from the spool, for which people often call this method semi-automatic.

Request for a quote

COMPANY TOR

Russia

The VIKING TIG 315 AC / DC PRO argon-arc welding machine is a one-piece structure, designed for power supply from a three-phase 380 V network and produces 315 A at a load of 60%. Special software functions significantly increase the performance factor of the device: HOT-START, ARC-FORCE, ANTI-STICK functions. Specifications: Voltage: V380 Max power: kW5.5 Max current: A315 Operating mode: DC/AC Product class: Professional Burner operating mode: 2-stroke / 4-stroke Pulse mode: yes Availability of the button for saving the selected parameters “MEMORY”, allows you to program 10 parameters for each welding mode (AC/DC). PULSE welding mode is a pulsed consumable-electrode welding (Possibility to use both direct current (DC) and alternative (AC). Waveform selection function (available in AC mode). Dot welding mode 2T and 4T. Adjusting of smooth drop of the terminating current. Adjustable inductance.

Request for a quote

KSL

Ukraine

KSL provides quality services of welding of various metals Metal welding is the process of fusing two metal parts together, using heat and pressure to form a strong metal bond. Heat is generated by an electric arc or flame, and pressure is applied using a welding tool. The process of welding is to melt metal surfaces and blend them together to form a homogeneous mass of metal. There are several welding methods, including MIG, TIG, and arc welding. Welding is rightly considered one of the most popular metalworking processes, which is found in many metal products. Main characteristics of KSL metal welding: Semi-automatic welding; Argon welding; Spot welding; Condenser welding. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #spotwelding #weldingstainlesssteel #aluminumwelding #metalwelding #tigweldingaluminum

Request for a quote

GOGEN LLC

Russia

Internal hot tub with heated water is often placed next to a house or a bathhouse. It is believed that in winter hot tubs provide the same effect as hot mountain springs. Internal stove MATEA 45 kW is suitable for hot tubs with a diameter of 2 meters or more Design, advantages and installation features of Internal stove MATEA 45 kW The equipment is manufactured from stainless steel AISI 340 2 mm using high-precision argon welding. The equipment has weight of 40 kg and dimensions (without chimney) of 110x70x29 cm (HxLxW). It is supplied with blower, lid and chimney 1m long and umbrella. You can additionally purchase scoop and a poker with long handles for cleaning ash. Ash Cleaning set. Special kit for indoor stoves, stainless steel scoop and poker with long handles for easy ash removal. It is made of food grade stainless steel AISI 304. AISI 304 stainless steel products do not rust and do not change their appearance during operation.

Request for a quote

GOGEN LLC

Russia

In winter, hot tubs give the same effect as hot mountain springs. Internal stove MATEA 25 kW is suitable for hot tubs with a diameter not exceeding 1.8 meters. The stove is made from a sheet of stainless steel AISI 304 2 mm using high-precision argon welding, placed in a hot tub, separated by a protective grill, eliminating the risk of scalding. Its weight is 30 kg, it has the following dimensions (without chimney):110x57x27 cm (HxLxW). It is supplied together with lid, blower, chimney 1m long and umbrella. Certain difficulties arise when cleaning ash. The problem is solved by purchasing a special kit. Ash Cleaning set. Special kit for indoor stoves, stainless steel scoop and poker with long handles for easy ash removal. It is made of food grade stainless steel AISI 304. The set includes a reliable bracket for wall mounting. AISI 304 stainless steel products do not rust and do not change their appearance during operation. Our set will last a long time and will delight its owners.

Request for a quote

GOGEN LLC

Russia

When choosing a stove for a hot tub, it is necessary to consider the size of the latter. External stove 45 kW MATEA is suitable for hot tubs with a diameter of 2 meters or more. The stove runs on wood; dry birch wood must be used. The stove is connected to the hot tub with heat-resistant hoses that are included in the kit. Advantages of external stove MATEA 45 kW The furnace is made of stainless steel AISI 304 2mm and 1.5mm with the use of argon welding. Its weight is 80 kg, dimensions without chimney: 77.5x70x48 cm (HxLxW). The stove kit includes the following: • Chimney of 2 pipes (1 m) with a canopy; • grate; • 2 hoses; • 2 flanges; • drain cock and clamps. The stove has double walls between which water circulates. In the process of burning wood, it heats up, moves up and down like a thermal pump. The heated part rises, reducing the pressure in the lower part, as a result, cold water from the hot tub is "sucked" into the stove.

Request for a quoteResults for

Argon welding - Import exportNumber of results

14 ProductsCompany type

Category

- Welding work - steels and metal (6)

- Ovens, wood-burning - professional (2)

- Stoves, heating (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Compactors and crushers (1)

- Fireplaces and stoves, ornamental and accessories (1)

- Gas, compressed (1)

- Steels and metals - welding and brazing (1)