- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- arc welding robots

Results for

Arc welding robots - Import export

DOGRAR METAL

Turkey

Fanuc Arc welding robot with 2 meters reaching capacity can weld 5 mm -20 mm parts with multi dimensional and efficient methods. Thin design makes the robot ideal for usage in different sectors from automotive to furniture industry. Unlike traditional welding methods, you can achieve the quality from first to last part. In addition to TIG welding, We are also working with other welding methods such as stainless steel welding (MIG/MAG) and spot welding depending on our client's needs and material preferences.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Metalworking companies are increasingly looking for practical solutions on how to quickly and easily carry out welding tasks. For small quantities, however, automation systems for welding have so far been difficult to implement, from an economical point of view. At the same time, it is becoming increasingly difficult to find qualified welders for manual processing. OTC DAIHEN EUROPE has developed EASY ARC, a new mobile welding robot system for workshop operation, which meets the economic and pragmatic requirements. EASY ARC includes a compact welding robot with intuitive OTC Easy-Teach control, which offers the operator with the perfect weld seam, thanks to the integrated expert system and manufacturer’s own 400A MIG / MAG power source inverter. The robot is mounted on a welding table that is prepared for holding standard clamping elements and equipped with rollers. The simple conversion of the system thus ensures appropriate flexibility in production.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4S from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1435 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3550 W Weight: 189 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Thanks to higher process speeds and shorter cycle times, the FD-B6 fulfills all requirements for the most demanding handling tasks. • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • More stable construction: 1.5 times the load capacity for welding tasks with different ranges. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 145 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Due to its outstanding arm length, it is particularly suitable for large work areas • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • Suitable for up to 6 kg payload capacities. Ideal for corresponding handling applications. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 278 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot FD-V8L with a refi ned design can handle all welding tasks and payloads of up to 8 kg. Due to its outstanding arm length, it is particularly suitable for large working areas. Faster cycle time: Designed for highest industrial speeds. Slim Design: Thanks to the slimmer lower arm design, less rotary motion is needed to reach the working position, thus preventing collisions with jigs and workpieces. User-friendly operation: Even the cables required for SynchroFeed are integrated into the lower arm, which prevents interference behind the robot arm. Stronger structure: Maximum payload now up to 8 kg. The use of different torches and sensors is possible. The main technical specifications at a glance: Number of Axes: 6 Max. payload capacity: 8kg Working Range (P-Point): R2006 mm Positional repeatability: +/- 0,08 mm Drive System: AC Servo Motor Drive Power: 5000 W Weight 273 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot, FD-V8, is equipped for all welding tasks and for load capacities of up to 8 kg. Thanks to integrated cable routing, the FD-V8 can still weld much more interference-free than any other robot in its class. It is 15% faster and the cycle times are accordingly shorter - ideal for maximum productivity. Interference-free: Interference-free welding thanks to integrated cable routing SynchroFeed-ready: Cables for the SynchroFeed / Servo-torch system can be integrated into the robot. Robot distances: Integrated cable routing enables reduced distances between the robots. Increased payload capacity: Higher load capacities of up to 8 kg. Higher performance: Up to 15% higher speeds. The main technical specifications at a glance: Number of axes: 6 Max. payload capacity: 8 kg Working Range (P point): R 1437 mm Positional repeatatbility: +/- 0.08 mm Drive System: AC Servo Motor Drive power: 3016 W Weight: 140 kg

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

Kawasaki's BA Series and RA Series arc welding robots use the latest arc welding technology to compete with the quality of a trained human welder. The robots are equipped as standard with special arc welding software that allows quick and easy programming of the process path. An adaptive welding function is available to change the position of the robot, the shape of the weld seam and the speed during welding in the case of variable weld connections. Their built-in intelligence, flexibility and high accuracy make Kawasaki's arc welding robots ideal for a wide range of arc welding applications.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

Kawasaki's BA Series and RA Series arc welding robots use the latest arc welding technology to compete with the quality of a trained human welder. The robots are equipped as standard with special arc welding software that allows quick and easy programming of the process path. An adaptive welding function is available to change the position of the robot, the shape of the weld seam and the speed during welding in the case of variable weld connections. Their built-in intelligence, flexibility and high accuracy make Kawasaki's arc welding robots ideal for a wide range of arc welding applications.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Access to the workpiece from the outer surface Installation close to the wall edge Linear welding with walking motion Circular welding on the rotating system Motion transfer with linear slides and trolleys Ability to connect welding machine, oxygen and plasma cutting unit Ability to create special applications and stations

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Clean and high-quality cutting edge Increased productivity through reduced scrap and labor costs Low cost maintenance and consumables Maximum system flexibility thanks to robot mobility Designed to run without human intervention Easy and efficient to program, even complex paths and shapes Provides better precision, customization, speed and safety Optimal material utilization Robotic Cutting Software; Parameters automatically adjusted regarding to material and thickness. Calculated tool-paths and robot movements can be verified with simulation. Robot paths and laser parameters can be easily calculated on the offline CAM and simulation software. Step data can be loaded, and paths can be determined from edges or faces of CAD data

Request for a quote

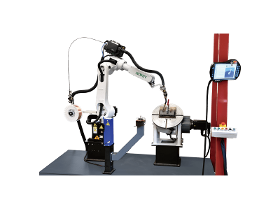

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

The ultimate cobot welding system available to buy and hire. ‘Ready to weld’ complete package The cobot welder includes all components being necessary for automated welding – perfectly matched to each other and easy to mount. The compact ” Ready to weld” cobot package is delivered completely ready for operation which ensures a problem-free integration into existing production processes. Exact, intuitive and safe A torque sensor in each axis allows the Cobotto be programmed and moved precisely. The intuitive operation significantly increases work efficiency. The user can make individual adjustments on the user-friendly touch control panel with macros specially developed for welding. In addition, the Freedrive option with foot switch and the intelligent safety concept guarantee sensitive and safe control of the cobot welder. Another special feature is the simple restart after an emergency stop as no extensive unlocking or free movement of the robot is necessary.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

Due to their high productivity, robotic welding systems offer cost advantages over manual welding, given the corresponding quantities. Benefit from high productivity and efficiency through perfectly matched welding components and fascinatingly good welding results of your products.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Arc welding robots - Import exportNumber of results

18 Products