- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- api 682

Results for

Api 682 - Import export

KROMA LTD

Serbia

Cartridge mechanical seals manufactured to meet API 682 (ISO21049) are meant for use in the petroleum, natural gas and chemical industries. During processing of crude oil various chemical compounds are being released, and designers should count on sealing fluids which could be: -under the very high pressure -under very high or very low temperatures -on very high or low pH value -very high or very low viscosity -abrasive -harmful, polluting and potentially explosive API 682 (ISO21049) specifies requirements and gives recommendations for sealing systems with aim to secure that the fluids with characteristics above could be transported: -with minimum waste -with maximum environmental protection -with minimum mechanical failure -with best price-quality ratio

Request for a quote

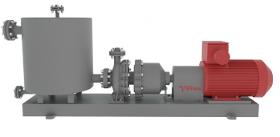

VILLINA LLC

Russia

Centrifugal pumps have well-known advantages such as uniform pumping without surges, the ability to create high pressures at low pump rate in multi-stage designs, long service life and others. Advantages: the fluid can be taken in at a point lower than the axis of the inlet suction pipe without using a pre-installed vacuum pump. - Purpose: transit of corrosive, toxic, explosive and flammable fluids at insufficient suction pressure; - Pump rate ranges: 0.8 to 450 m3/h; - Head ranges: 3 to 132 m; - Self-priming height (depth): up to 6 metres; - Seal type: magnetic coupling according to API 685 or tandem mechanical seal according to API 682; - Climatic version: for moderate and for moderate and cold climate; - Temperature of the pumped fluid: for GNGC-S, GNGC-S-M up to plus 350°С, for NCG-S up to plus 450°С; - Shaft speed: 1,450 or 2,900 rpm; - Structural design: ОН-2 single-stage back pull-out pump according to API 610 or a single block.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

This rugged and reliable liquid ring compressor expaned the NASH Vectra compressor range with a model that operates at up to 4 bar G (60 PSIG). The XM-150 comes in 681 and 682 compliant versions and is specifically designed for the higher pressures and performance requirements found in many process applications, including vapor recovery, flare gas recovery, biogas, corrosive gas handling (e.g. VCM and chlorine) and hydrogen compression. The NASH Vectra XM-150 liquid ring compressor provides the same quality and reliability you've come to expect from the existing Vectra series with these features: Single, conical port design; Between bearing rotor/shaft design; single pressure boundary sealing point; API-681 and API-682 category II/III compliance; increased bearing life; 316 stainless steel construction; and horizontal, self-draining inlet/discharge nozzles. The rugged construction and easy to service design of this liquid ring compressor reduces maintenance requirements and minimizes downtime for maintenance and repairs in even the most demanding applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Api 682 - Import exportNumber of results

3 ProductsCountries

Company type

Category