- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aoi

Results for

Aoi - Import export

JUKI AUTOMATION SYSTEMS GMBH

Germany

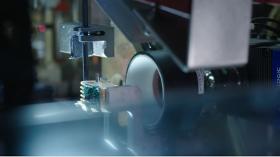

Optical Inspection / Solder Paste Inspection JUKI’s RV2 3DH analyzes the three dimensional shape of the completed board and compares the shape against the specification based on the outlines, heights, and brightness of the components and solder. It then judges whether the board is OK or NG (no good) based on the analysis. The 2D check function is also available.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. For components of the most varied shapes and with diverse electronics components, we will set up our AOI stations according to individual needs and provide reliable optical control of the overall assembly. Automatic optical inspection of your components is naturally part of our service range.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. The 3D automatic optical inspection of SMD components combines 2D and 3D inspection at maximum speed. Some of our machines allow an inspection in 360 ° steps. Depending on the machine, excellent dynamic properties and the highest positioning speed can be achieved on the basis of linear drives.

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Two modern AOI devices (automatic optical inspection) in 2D and 3D secure the manufacturing process during the SMT assembly. We use our X-ray inspection device to control the soldering process on components with connections under the housing. In addition to quality assurance, we also offer test and inspection procedures that are precisely tailored to your needs. In addition to circuit-specific in-circuit and burn-in tests, we can carry out application-related function tests in our test field. For specific tests, many customers send us the test procedures with the appropriate equipment directly. In this way we can check the functionality of your assembly without you having to tell us what exactly the tests are checking. Your advantages with A + B Electronic -Test procedures tailored to your needs -We are not just a service provider, we are a technology partner: A + B Electronic thinks your project with you and together we can successfully bring it into series production

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The AOI system is designed for simultaneous inspection of printed circuit boards top and bottom side. It has two multi-LED illuminated scan units with parallax free view. Those systems are also available for single side as for top or bottom view. The system includes complete set of modus control units. The transport module has a length of 1200mm (47.2 in). Characteristics: Double System for dual side simultaneous inspection for printed circuit boards. Simultaneous display of all results of double side inspection. Combination of different inspection tasks such as SMD placement, THT solder joints, conformal coating and full screening for solder beads. Capture of any number of barcodes and data-matrix codes on the multi PCB. Scan range 420 x 530 mm or 300 x 400 mm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The almost maintenance-free modusAOI MCS18/42-Inline was specially developed for transport conveyor modules in production lines. Existing lines can easily be retrofifitted with this system. The small, cost effective system comes with a 18 or 42 megapixels camera, control unit, modus software and led lighting inclusive controller. Characteristics: Single system for inspection of printed circuit boards from the top side. Combination of diverse application tasks such as SMD placement, pre-reflow, chip control, THT fitting, conformal coating and full screening for lost components. Reads barcodes and data-matrix codes in any position and quantity even on multi-PCBs.

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MLD1200 V2.0-OS is a single-sided offline AOI system for the inspection of assembled printed circuit boards from the top. It has one multi-LED illuminated image scanner as well as our patented parallax-free lenses. It includes a modus control unit with the latest modus software. An optional trolley is available. Characteristics: Single system for inspection printed circuit boards from the top side. Combination of different inspection tasks such as SMD placement, THT solder joints, conformal coating and full screening for solder beads (solder balls). Capture of any number of barcodes and data-matrix codes on the multi PCB. Scan range 300 x 400 mm

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MLD1200 V2.0-DS is an offline dual AOI system for the inspection of assembled printed circuit boards from both sides at the same time. It has two multi-LED illuminated image scanners as well as our patented parallax-free lenses. It includes modus control units with the latest modus software. An optional Trolley is available. Characteristics: Dual system for double-sided simultaneous inspection for both sides of printed circuit boards. Combination of different inspection tasks such as SMD placement, THT solder joints, conformal coating and full screening for solder beads (solder balls). Capture of any number of barcodes and data-matrix codes on the multi PCB. Shows the test result of both sides at once. Scan range 300 x 400 mm

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The triple AOI system is designed for simultaneous inspection at the return conveyor and from top and bottom before and after wave soldering oven. It has three multi-LED illuminated scanner units, as well as patented special optics which generate a parallax free image. The System includes three modus control units. The transport module has a length of 1200mm (47.2 in.). Characteristics: Triple system for simultaneous inspection of top and bottom before and after the soldering process. Optional automatic cleaning of the lower inspection area with an air knife. Combination of different inspection tasks such as SMD placement, THT solder joints, conformal coating and full screening for solder beads (solder balls). Capture of any number of barcodes and data-matrix codes on the multi PCB. Scan range 420 x 530 mm

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MCS42-SEL-AL is a cost effective camera-based AOI system. This solution is optimized for economical and flexible inline inspection of the several production processes. The small and inexpensive system comes with a 42 megapixel, high-definition industry camera and a PC equipped with the powerful modusAOI software whose development includes professional experience of two decades. Characteristics: Single system for inspection of objects. Combination of diverse application tasks in the THT area which take place before a wave soldering or selective soldering oven. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The system comes with four 42 megapixel cameras and a high-performance control unit. LED lighting including LED control is also included in the delivery. The entire picture of the image analysis is orthogonally calibrated. Characteristics: This system can meet the toughest requirements for the inspection of bipolar plates in various production stages. The system has been adapted to the high requirements of the inspection of bipolar plates. The image acquisition time of approx. 2,5 seconds with a resolution of 24 um is outstanding. Inspection with the high-resolution system cameras is carried out using the tried and tested modusAOI software. Test possibilities: Position and minimum thickness of the graphite coating in the central area Checking the surfaces that should not be coated Coating contamination (graphite/screenprint) Testing of a defined target contour in screen print Damage to the metal at the edge (balcony) of the workpiece

Request for a quoteResults for

Aoi - Import exportNumber of results

12 ProductsCountries

Company type