- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- anodes

Results for

Anodes - Import export

STANDART ALUMINIUM

Turkey

Anodizing surface treatment is a method used to change the surface chemistry by electrolysis method. Anodized coating, in addition to maximizing the resistance to corrosion in aluminum profiles, provides an aesthetic appearance and provides resistance against scratching. The processes performed in our anodized coating surface treatment are applied within the framework of European QUALANOD and TSE standards, with features such as UV resistance and color permanence.

Request for a quote

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

All surface treatments called classics are possible, based on the final requirements. Phosphating ; Black Oxide ; Epoxy Paint ; Anodizing ; Hard Chrome Plating ;Electrolytic Zinc Plating; TICN ;Glass Blasting (Glass Beads)

Request for a quote

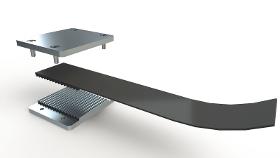

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER timing belt clamping plates can be made of many different materials, e.g. aluminum, steel or stainless steel. Keiper can produce them in all pitches and designed according to your specifications and drawings. This means that you will receive the optimal solution for the intended application and load. Our timing belt clamping plates work together optimally with our extensive and complete range of timing belts: in other words, a perfectly matched system for your requirements. We also have a large number of standard aluminum clamping plates on stock, which can be reworked according to your specifications (e.g. bores and mechanical processing based on drawings). Furthermore, such special surface coatings as hard coating, anodizing, zinc coating or bronzing improve the corrosion and wear resistance.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Aluminium Anodizing: A Premium Surface Treatment Solution At Aluminium Anodizing, we take immense pride in offering a top-notch anodizing process that sets the industry standard. With our state-of-the-art facilities and expertise, we specialize in conducting anodizing procedures up to an impressive thickness of 20 µm and a length of 7,000 mm. Our meticulous attention to detail ensures that each anodized product meets the highest quality standards. Whether you require standard or special colors, our skilled technicians are adept at delivering exceptional results that cater to your specific needs. What sets us apart is our unwavering commitment to excellence, demonstrated by our prestigious Qualanod certificate. This certification serves as a testament to our dedication to providing unparalleled quality and reliability in every anodizing project we undertake.

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Anodizing stands for electrolytic oxidation of aluminum and is a process for strengthening the natural oxide layer present on aluminum through anodic oxidation. Unlike traditional electroplating processes, anodizing dissolves the top layer of aluminum and converts it into aluminum oxide. The resulting oxide layer protects the underlying workpiece from corrosion.

Request for a quote

PLANSEE SE

Austria

Tungsten and tungsten alloy electrodes are used to produce the arc in high-intensity discharge lamps. Tungsten electrodes from Plansee excel due to their outstanding physical and mechanical properties: a high melting point, low vapor pressure, low thermal expansion, good thermal conductivity and a low electron work function. Plansee supplies anodes, cathodes and support rods. With special alloy additives, Plansee improves the high-temperature dimensional stability, electron work function, formability, machinability and thermal conductivity of the material. For cathodes, aluminium-potassium silicate (AKS) or lanthanum oxide-doped tungsten is available. A new addition to the range: WLZ, a tungsten material doped with lanthanum and zirconium oxide. WLZ is the non-radioactive alternative to thorium-doped materials.

Request for a quote

MARXAM PROJECT

Poland

All required protective coatings are made in certified external companies. The basic condition for cooperation is meeting all environmental requirements. Our capabilities include the following metal protective coatings: - aluminum anodizing (soft and hard); - cataphoresis (electrophoretic painting); - electropolishing; - galvanic zinc; - hot-dip galvanized (galvanizing metal); - powder coating. As a production company, we offer: - metal sandblasting of crude steel; - removing paint coatings by sandblasting and soda blasting (without heating and damaging the surface); - glass blasting of stainless steel and aluminum; - unifying the surface after machining and welding; - large-area painting with a hydrodynamic, airless unit.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Passivation is the chemical treatment of surfaces to increase corrosion protection with excellent conductivity. Positive for subsequent painting and powder coating processes, to reduce fingerprint sensitivity and to change the appearance (gloss, color). Maximum measurements 4000 x 1000 x 360 mm

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

A combination of the anodizing process with coloring (absorption dyes and alternating current coloring) offers a wide range of design, functional and aesthetic options for creating an attractive surface (e.g. for cases, dials, front panels, jewelry, etc.). Maximum measurements 700 x 700 x 500 mm

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

The anodizing process is the creation of an oxidic protective layer through anodic oxidation in the uppermost aluminum zone. A 5 to 25 μm thin, resistant hard layer is created that protects against corrosion. — Semi-automatic anodizing plant, processing dimensions 4000 x 1000 x 500 mm — hand anodizing plant, processing dimensions 2500 x 700 x 500 mm

Request for a quote

CORROCONSULT UK LIMITED

United Kingdom

Our Company Capability Statement is also available in Spanish, detailing a comprehensive list of our services, a summary of our recent key experience and what sets us apart from our competitors

Request for a quote

CORROCONSULT UK LIMITED

United Kingdom

Our Company Capability Statement is also available in Portuguese, detailing a comprehensive list of our services, a summary of our recent key experience and what sets us apart from our competitors

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CORROCONSULT UK LIMITED

United Kingdom

Our Company Capability Statement has been updated detailing a comprehensive list of our services, a summary of our recent key experience and what sets us apart from our competitors.

Request for a quote

YILDIZ CILA POLISHING COMPOUND AND BUFF MANUFACTURER

Turkey

Gives standard brightening effect to Aluminium profiles during polishing process.

Request for a quote

DUTCH SCRAP RECYCLING B.V.

Netherlands

Carbon Anode Butt Carbon Anode Scrap/ graphite scrap 1.for copper smelting 2 replace foundry coke as fuel 3 well cleaned Features: 1.Anode scrap is high in calorific value and low in moisture; 2.Anode scrap can be divided into different sizes by crushing and screening, including 10cm, 20cm above and powder. 3. It can also be used as the smelting fuel.

Request for a quote

DUTCH SCRAP RECYCLING B.V.

Netherlands

Adopt the high-quality petroleum. Our products has hig destya hig mechnical strength, good electrical condctvity and high corrosion resstance. Ordinary Power Graphite Anode Plate and Impregnating Graphite Anode Plate are mainly used in various types of stove for smelting rare earths. Various Specification of the Ordinary Power Graphite Anode Plate and Impregnating Graphite Anode Plate can be customized according to customer's requirement.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor socket 9902A made of solid aluminum with 2 slots. The reversible cover is anodized in natural aluminum or can be covered with carpet, linoleum etc. and closes in a straight or angled shape even when the standard plug is inserted. Further equipment variants on request.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The material is aluminum. The process is CNC milling. The finish is black anodized.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Quality Anodized Aluminum Parts Ming Xiao Manufacturing Co., Ltd engaged in precision turning parts manufacuring more than 20years, we have a lot of different machines for different turned parts & machined parts. we custom quality anodized aluminum parts according to customers drawing or samples. What is anodizing? Anodizing is an electrolytic process that deposits a chemically stable oxide layer on aluminum surfaces. The resulting oxide film is thicker and stronger than the native oxide coating of aluminum. It is hard, porous, and transparent, making it an integral part of metal surfaces so it will not peel or peel. effect: protective decorative Insulation Improves adhesion to organic coatings Improves adhesion to inorganic coatings We are specialize in custom Anodized Aluminum parts, If you have any aluminum machined Parts need done anodizing,Welcome contact us to discuss about your projects.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Material:Stainless steel, copper alloy,aluminum alloy and so on Surface treatment:Polishing, Zinc plating, Nickel plating, Chrome plating, powder coating, Anodizing, E-coating Drawing operation:PDF, JPG, Auto CAD, Pro/Engineer, Solid Works, UG. Etc. Industry:Automotive, Electrical, Building, Furniture,Mechanical, Machine assembly, Computer, Air industry. Electronics etc. Professional team :Over 10 years experience in metal fabrication Delivery time:Strictly according to customer confirmed order. Package detail:Standard export package or as customers' specific requirement

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Our Service High precision CNC parts manufacture Metal and plastic parts manufacture Prototypes manufacture Mass production manufacture

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: Aluminium 2.Machining type: precision cnc milling 3.Surface: Black anodized 4.Tolerance:+/-0.05mm 5.Application : Machine parts 6.Quality,reliability and long product life

Request for a quote

STANDART ALUMINIUM

Turkey

S-Clamp SpeedPro series are the solar mounting clamps which are the most appropriate clamps for universal usage. S-Clamp SpeedPro series are compatible with all Standart Aluminium Solar Mounting Systems. Product is made of 3 pieces. Available in black anodized option and grounding pin! Compatible Panels (Height): 35, 40, 42 and 45 mm. Length Options: 50, 60, 70 and 80 mm.

Request for a quoteResults for

Anodes - Import exportNumber of results

214 ProductsCountries

Category

- Aluminium alloys (25)

- Zinc and zinc alloys (20)

- Structures, aluminium (12)

- Milling - steels and metals (11)

- Aluminium and aluminium alloys (9)

- Screen printing on metal (7)

- Machine tools, metal machining - parts and accessories (6)

- Polishing - steels and metals (6)

- Aluminium coatings (5)

- Components and parts for large household appliances (5)

- Moulds, precision (5)

- Pipes and tubes, aluminium (5)

- Anti-corrosion coatings (4)

- Hinges (4)

- Stainless steels (4)

- Aluminium sheets and bands (3)

- Lighting (3)

- Solar energy (3)

- Automobiles (2)

- Bicycle accessories (2)