- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- annealing

Results for

Annealing - Import export

PARSMEGA MAKINA

Turkey

Forced annealing; It is used in flour manufacturing facilities to provide high moisture content to wheat in a shorter time and with less water. It is used to give intense and standard tempering to wheat. The wheat to be moistened enters the machine inlet in an automatically controlled manner. Water inlet is controlled by an electronic or mechanical flowmeter. Wheat and water enter the machine at the same time. Provides 5% annealing even at the shortest distance. Forced annealing; It is designed to add (temper) the highest amount of water to wheat. The main bodies, made entirely of metal, are easily removable. The rotor consists of many distributor pallets on it. - Wheat and water are mixed throughout the body thanks to the pallets on the rapidly rotating rotor. With this feature, it performs the annealing process at the desired rate by applying strong rubbing, rubbing and forcing to the wheat. It is possible to reach high capacities with this machine.

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

304 quality is the most commonly, and in a versatile way, used stainless steel in the world. It has ability to be perfectly shaped and welding capability. Austenitic structure of 304 provides to perform deep drawing without intermediate annealing, and therefore, it is preferred in manufacturing which requires deep drawing such as sink, natural gas chimneys and saucepan. It can be used for various purposes in sectors such as industry, architecture, transportation.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your annealing / bright annealing / normalizing operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Annealing / Bright annealing / Normalizing control Solution is supplied with a PROTHERM controller and either an AccuCarb® LTA probe or FurnaceDoctor® FX analyzer or with Protherm ActivePLC™, FurnaceMeter™, AtmoSense™ and UPC oxygen probes for a variety of furnace types. FEATURES • AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Latest achievements in process control • Cost-effective module configurations * depending on the options chosen

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: round Material: 1.4034 (X46Cr13) Type of production: hot-rolled Surface: annealed Standard: EN 10088 eClass 9.1: 35010312 UNSPSC 11.2: 30102405 Dimensions: Diameter (mm): 100 Length (mm): 5,000

Request for a quote

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

Annealed wire for making reinforcements For tying up solid waste. Straw baling.

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

Our Heat Treating Suppliers are certified by Aeronautical and Automotive Industries. Annealing Normalizing Stress Relieving Quenching and Tempering Vacuum Hardening Homogenization Decarburization Nitriding Carburization Case Hardening and more

Request for a quote

PARSMEGA MAKINA

Turkey

Measuring the moisture of the flowing raw material with high precision. Calculation of the amount of water to be given according to the desired humidity amount in lt/hour Control of the calculated amount with the electronic water flow meter placed in the system Calculation of faults from the operator panel Instant monitoring of raw material moisture in % Ability to instantly monitor the amount of water given in lt/hour Ability to monitor the amount of water that needs to be given in lt/hour Ability to monitor the total amount of water given in liters. Ability to connect the system to the computer at any time and perform all controls from the computer without having to go near the device.

Request for a quote

PARSMEGA MAKINA

Turkey

In flour and semolina factories, it ensures rapid mixing of the product with water and helps shorten the tempering time. Their rotors consist of steel pallets. It is an effective machine in peeling as the grain moves by being squeezed inside the machine.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication for applications where pastes or powders have been used up until now Chain lubrication of heavily loaded chains in temperature ranges in which oil or grease lubrication is not possible For example, in annealing, stoving and baking ovens for aluminium tube manufacturing, in painting systems or in baking lines Advantages and benefits Hygienically harmless as defined in German LFGB Approved by Nuremberg LGA for use in food processing technology NSF H2 registered Economical due to low consumption Optimum wear protection at high pressures and extreme temperatures Can be mixed with water in ratio of up to 1:5

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Spring steel is a model of load-bearing capacity. Characteristic for this material group are homogeneous microstructures and optimal surfaces. It stands for above-average service life, dimensional stability and constant quality in every end product. Spring steel obtains its special properties through special treatment in the production process, whereby the even distribution of the carbon content is of particular importance. It undergoes several rolling processes and repeated heat treatments in numerous work steps - this is how we guarantee optimum quality for your products! C 67 S - C 100 S/➔ according to DIN EN 10132 - 4 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This material group stands for breaking strength, service life and wear resistance. Due to these properties, quenched and tempered steel is always used where high strength, yield strength and high toughness are required for highly stressed machine parts. C 22 E, C35 E, C 45 E/➔ according to DIN EN 10132 - 3 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed ground grit 240, grade 1.4301, 10-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 12-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed ground grit 240, grade 1.4301, 10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 10-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded, not annealed,Tol. EN EN ISO 1127, DIN EN 1027-7 TC1, grade 1.4301, 5-0.75 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAPPERT INTRAMET SA

Belgium

Tube round welded, not annealed Tol. DIN EN ISO 1127, DIN EN 10217-7 TC1, grade 1.4301, 10-2 mm

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

It is the general name of the placement aimed at improving the mechanical properties of heat treatment metals. A type of metallurgical process. Generally, it is done by annealing metals in a certain way, bringing their structure to the desired stage.

Request for a quote

ALSAN ALUMINYUM PROFIL VE REKLAM MALZEMELERI LTD

Turkey

PLANSEE SE

Austria

Plansee supplies sintering and annealing boats made of molybdenum, tantalum, niobium, tungsten and various alloys such as ML or TZM. They are dimensionally stable, corrosion resistant against many chemicals and have a very good creep resistance. Whether is is continuous or batch furnaces - Plansee has the right solution at hand. For best quality surfaces we supply sintering and annealing boats with coatings made of aluminum and zirconium. Plansee produces its boats according to the customer's drawing in different sizes and shapes.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quoteResults for

Annealing - Import exportNumber of results

91 ProductsCountries

Company type

Category

- Steel sheets and strips (13)

- Aluminium sheets and bands (12)

- Pipes and tubes, aluminium (7)

- Sections - non-ferrous metal (6)

- Aluminium and aluminium alloys (4)

- Oils, cooking - machinery and equipment (3)

- Steel, special (3)

- Welding, soldering and brazing - equipment and supplies (3)

- Brazing - equipment and supplies (2)

- Steels and metals - machining (2)

- Steels, nickel (2)

- Aluminium alloys (1)

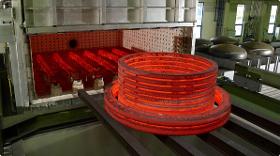

- Casting, steel (1)

- Heat treatment of steels and metals (1)

- Laser - cutting and welding machines (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Pipes and tubes, titanium (1)

- Plates, perforated - ferrous metal (1)

- Silicones (1)

- Sintering - steels and metals (1)