- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- angle sensor

Results for

Angle sensor - Import export

MEGATRON ELEKTRONIK GMBH & CO. KG

Germany

The MUP potentiometers in 22 mm housing are suitable for applications in which a compact sensor with good quality and reasonable price is important. The precision potentiometers of the series MUP are space-saving, economical and universal wirewound potentiometers. Models with electrical rotation angle of 320° (MUP1300 / 1350) and 270° (MUP1307) are available.

Request for a quote

MEGATRON ELEKTRONIK GMBH & CO. KG

Germany

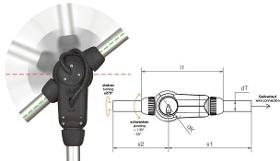

The MCP30 potentiometers with precision ball bearings and servo flange are suitable for applications where a very long life with high linearity and precisely mountable sensor is important. The precision potentiometers of the MCP30 series are designed for high demands on accuracy and reliability. They have good linearity and excellent life expectancy. The potentiometer is equipped with a servo flange for precise mounting. In closed loop controlled systems, the conductive plastic potentiometers can be used particularly advantageously. As passive components, they do not cause any dead times due to signal propagation and the signal is infinitely available. Very long life Very precise sensor Servo flange for precise mounting 2 Precision ball bearings Robust metal housing

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

The inductive linear position sensors of the Ri series operate contactless and wear-free according to a new, revolutionary measuring principle: The angular position is not detected via a positioning magnet but via an oscillating RLC circuit. The sensors are thus completely immune to magnetic fields such as generated by large motors for example. The measuring range of the rugged angle sensors is 360°. As starting variants analog voltage or current outputs and switching outputs are available.

Request for a quote

IGUS® GMBH

Germany

robolink® multiple-axis joint robolink® configurator

Request for a quote

IGUS® GMBH

Germany

robolink® multi-axis joint robolink® Configurator

Request for a quote

IGUS® GMBH

Germany

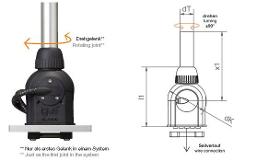

DOF* rotating Can only be used as the first joint in a system. Material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) *degree of freedom Balls: DOF* rotating Can only be used as the first joint in a system. Material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) *degree of freedom Balls:

Request for a quote

IGUS® GMBH

Germany

Oscillatory robolink® joint - optional with angle sensors material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) Balls: Oscillatory robolink® joint - optional with angle sensors material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) Balls:

Request for a quote

IGUS® GMBH

Germany

robolink®-based joint: Bearing ring rotation on the basis of PRT-01-50 iglidur® J gliding elements rotating on aluminium HC Weight: 1.250 g max. load: privot 20 Nm, rotate 10 Nm Pivoting angle: 180° (± 90°) Rotation angle: 180° (± 90°) Material: Fine polyamide PA 2200, VA screws, Dyneema ropes, aluminum HC bearing (alternativ iglidur® J) A = privoting ±90° B = rotating ±90°

Request for a quote

IGUS® GMBH

Germany

robolink®-2-axial joint: Weight: 400 g max. load: pivoting 12 Nm, rotating 5 Nm Pivot angle: 180° (+180°/0°) Rotation angle: 340° (± 170°) Material: Fine polyamide PA 2200, VA screws, Dyneema ropes, aluminum HC bearing (alternativ iglidur® J) A = rotating ±270° | B = pivoting ±180° - 0° C = rope run

Request for a quote

IGUS® GMBH

Germany

Drive units with 3 DOF with angle sensors Drive units with 4 DOF with angle sensors Drive units with 5 DOF with angle sensors robolink® drive units for all articulated arms Significantly expanded workroom Freely configurable arm length through modular design Step motor driven Alternative drive/control systems easily possible Drive units with 3 DOF with angle sensors Drive units with 4 DOF with angle sensors Drive units with 5 DOF with angle sensors

Request for a quote

IGUS® GMBH

Germany

Drive unit for up to 6 DOF: Freely selectable arm lengths Drive with igus® step motors 6-axis unit completely mounted on a sturdy aluminium base Ready for connection to individual controls Articulated arms with or without optional angle sensors

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental rotation sensors are used wherever displacement, positions or speeds have to be measured accurately. They are therefore important interfaces between the mechanical and electronic parts of a machine. Mechanically robust, electrically reliable and resistant to extreme ambient conditions; these are the outstanding properties offered by this sensor. Typical applications include —Machine tools —Wood and plastic machining —Textile machines —Lifts —Door systems —Paper machines —Drive equipment —Assembly and handling equipment —Packaging machines —Scales —Test machines —Conveying equipment —Doors and gates Specific characteristics —Degree of protection IP65, all-around —Robust —High resistance to interference —Rotary speed sensor: 60 pulses/turn (standard) —Angular displacement sensor: up to 3600 pulses/turn —Detection of rotation direction (channels A and B) —Reference pulse (channel N) —Special versions on request

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

A very cost effective and compact potentiometric angle sensor with integrated power and reset spring. Available on request! For further information please contact: automotive@novotechnik.de, +49 711 4489-222 Automotive-Applications.pdf

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

As an angle sensor that is both accurate and economical, this rotary potentiometer is suitable for all types of analog angle measurement up to 350°. Typical fields of application include: —Position feedback in servo-systems —Pendulum weighing machines —Cam and butterfly flap positions —Jockey roller controllers —Measuring the tension of threads and tape —Trigonometric measurements at joints The heart of the potentiometric angular displacement sensors is an extremely precise, low-wear resistor track made of plastic. Due to its high resistance to abrasion, the sensors are particularly suitable for measurements for the purpose of quality assurance in ongoing production, where a long service life and large numbers of rotations are required. The potentiometric angular displacement sensor uses a multi-finger slider system with precious metal contacts. This ensures good contact even when moving at high speed and in the presence of vibrations.

Request for a quote

SIKO GMBH

Germany

A combination of the MSAC506 magnetic sensor and the MRAC506 magnetic ring forms a system for absolute angle measurement. The MSAC506 sensor has an SSI interface with a resolution of 12 Ö 16 bit. There is also an analogue output (1 VSS) with 64 periods for dynamic position tracking. The sensor has an LED for distance monitoring. Magnetic absolute encoder single-turn. Compact design. Resolution 12 … 16 bits. Additional analog Sin/Cos 1 VSS signals. Reading distance ≤1 mm

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques. An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface.

Request for a quote

SIKO GMBH

Germany

Freely programmable 5-digit measurement display for the evaluation of incremental measurement information obtained from length and angle sensors. LED display (1 line of 5 digits). Input for incremental encoder recognition of the counting direction for length and angle measurement. Free programming via front keyboard. Non-volatile parameter storage (EEPROM). With reference connection. Integrated quadruple evaluation of counting pulses. Compact design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZEMO VERTRIEBS GMBH

Germany

Electric Impulse Tool with Torque Control and Angle Monitoring. The YOKOTA electric system wrenches with integrated torque transducer and angle sensor offer a large reduction of energy consumption, a high degree of accuracy and fantastic work efficiency. Faulty tightening detection with maximum accuracy due to the use of an integrated torque transducer and also an integrated angle sensor. Torque transducer and angle sensor located directly at the front of the main shaft, giving the best accuracy of measurement. The angle sensor is an extremely compact (PAT) rotary encoder that detects both angle as well as direction by 1 degree, signal transmission contactless. Due to the newly developed outer rotor servo motor and the composite body, the Yokota system e-wrench has the lightest weight in its class. For cooling of the motor it is equipped with a fan that reduces motor size (and weight at the same time). For cooling of the impulse unit it is equipped with a separate fan. [...

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Hybrid Technology – Smart Assembly Solutions The YOKOTA electric system wrenches with integrated torque transducer and angle sensor offer a large reduction of energy consumption, a high degree of accuracy and fantastic work efficiency. Torque transducer and angle sensor located directly at the front of the main shaft, giving the best accuracy of measurement. Faulty tightening detection with maximum accuracy due to the use of an integrated torque transducer and also an integrated angle sensor. During the tightening process, four different variables are measured and monitored: Torque - Angle - Time - Nº. of Impulses. Torque transducer measures directly and transmits the signals contactless. Detects cross threads, double hits, contamination, etc. Special feature to prevent cross threaded tightening: reversely rotating a bolt to a preset angle at the start of tightening. Combinations of buzzers and LED (Green / Red) for operator feedback on OK / NOK tightenings. [...]

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Application: Motor Management Electronic pedal sensor modules comprise of an accelerator pedal, angle sensor, and mechanics for simulating the driver's traditional sense of the accelerator pedal. When the accelerator pedal is pressed down, the pedal sensor transmits information to the control electronics. Based on this information, the position of the throttle valve is calculated. Automotive-Applications.pdf For more information please contact: automotive@novotechnik.de, +49 711 4489-222

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Application: E-gas, idle speed control The information detected from the pedal sensor are transmitted to the electric motor-driven throttle valve positionier via control and correction electronics. The current throttle valve position is measured by an integrated or adapted angle sensor. The idle controller regulates independent of the load the idling speed or the engine through the throttle position. This leads to an optimised fuel consumption. Automotive Applications.pdf For more information please contact: automotive@novotechnik.de, +49 711 4489-222

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The AT multi-turn actuators are characterized by their compact shape and clear design. Integrated grooves for sensor mounting. Angle of rotation from 0° to 180°.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Model 9180 supports force, pressure and torque sensors operating on the strain gauge principle, as well as the connection of position and angle sensors in potentiometer or DC/DC configuration. It also allows the measurement of process signals ± 1 V/ 5 V/ 10 V or 0 ...1 mA, 0(4) ... 20 mA. The current measured value is indicated on the 14 mm high LED main display, while a second display located directly below provides a reading of the peak value. The display is particularly suitable for highly accurate measurements due to the high accuracy of 0.1%. It is also possible to monitor up to 4 limit values and provide the results via relay or transistor outputs. Thus the process value display can be used for classification, process and control tasks. The current measured value is frozen on the display by activating an external HOLD signal. The TARE function is useful for balancing out previous loads for example.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications. GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

SIKO GMBH

Germany

Other versions Profile MA07/1: Incremental, length, angle, rotational speed or number of pieces measurement LED display (1 line of 5 digits) Inputs for incremental sensors, length and angle measurement, rotational speed or number of pieces Free programming via front keyboard Incremental measurement function (operating mode I), actual value memory (operating modes I and S) With reference connection Programming enabled via external input (keyswitch) Compact design

Request for a quote

SIKO GMBH

Germany

Freely programmable, compact measurement display. Optionally, the positions of incremental measurement systems or rotary speeds as well as number of pieces can be displayed combined with commercially available initiators or light barriers. Incremental, length, angle, rotational speed or number of pieces measurement. LED display (1 line of 5 digits). Inputs for incremental sensors, length and angle measurement, rotational speed or number of pieces. Free programming via front keyboard. Incremental measurement function (operating mode I), actual value memory (operating modes I and S). With reference connection. Programming enabled via external input (keyswitch). Compact design.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

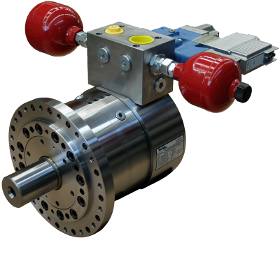

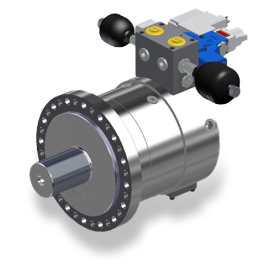

Thanks to a wide range of accessories, Hense operators can be individually configured for a wide variety of applications and optimally matched to the function of the overall system. To ensure perfect and safe operation, we are on hand to help you select and optimally coordinate all components.Servo valves, proportional valves and switching valves with different nominal sizes Pulsation damper for smoothing vibrations and uneven flow rates Subplates for positioning valves and pulsation accumulators close to the motor High-resolution rotation angle sensors that are coupled directly to the swivel motor shaft by means of a torsionally rigid coupling Pressure sensors Torque measuring shafts or reference torque measuring disks Clamping sets, shrink disks or profiled hubs for torque transmission Torsionally rigid couplings for reliable torque transmission with simultaneous shaft displacement Angled flanges for mounting the swivel motors parallel to the axis

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quoteResults for

Angle sensor - Import exportNumber of results

86 ProductsCountries

Category

- Sensors (58)

- Potentiometers (46)

- Electric motors and parts (8)

- Measurement and control instruments (2)

- Automation - systems and equipment (1)

- Construction machinery (1)

- Cylinders, pneumatic (1)

- Electric tools (1)

- Measurement - Equipment & Instruments (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Thermometers (1)

- Welding, soldering and brazing - equipment and supplies (1)